Sealing device for heat treatment furnace provided with disc rollers and heat treatment furnace provided with the same

A heat treatment furnace and sealing device technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems that the shape cannot be kept uniform, the contact part is worn, the heating gas leakage channel, etc., and achieves good hot gas prevention performance and good contact state. , The effect of uniform adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

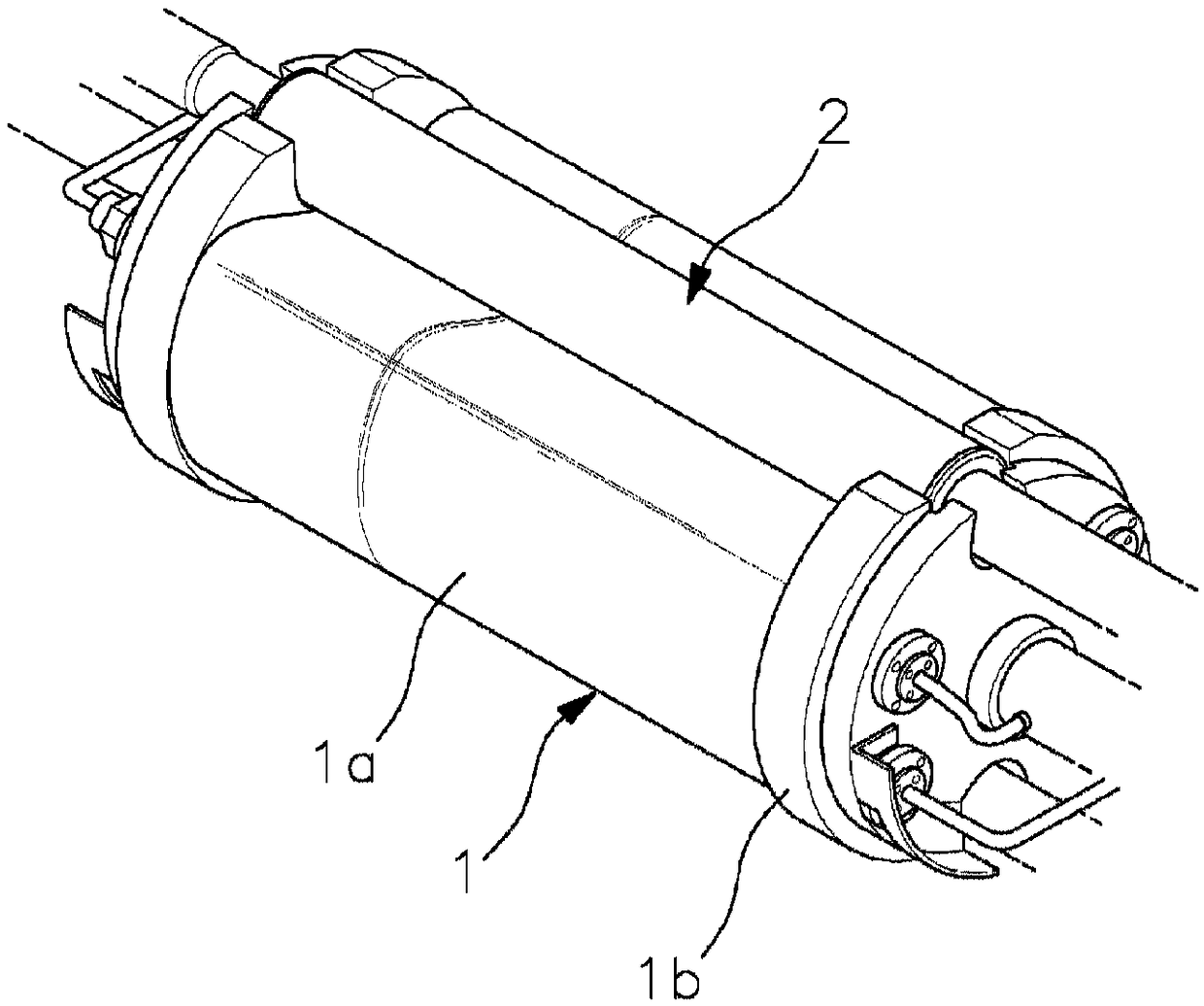

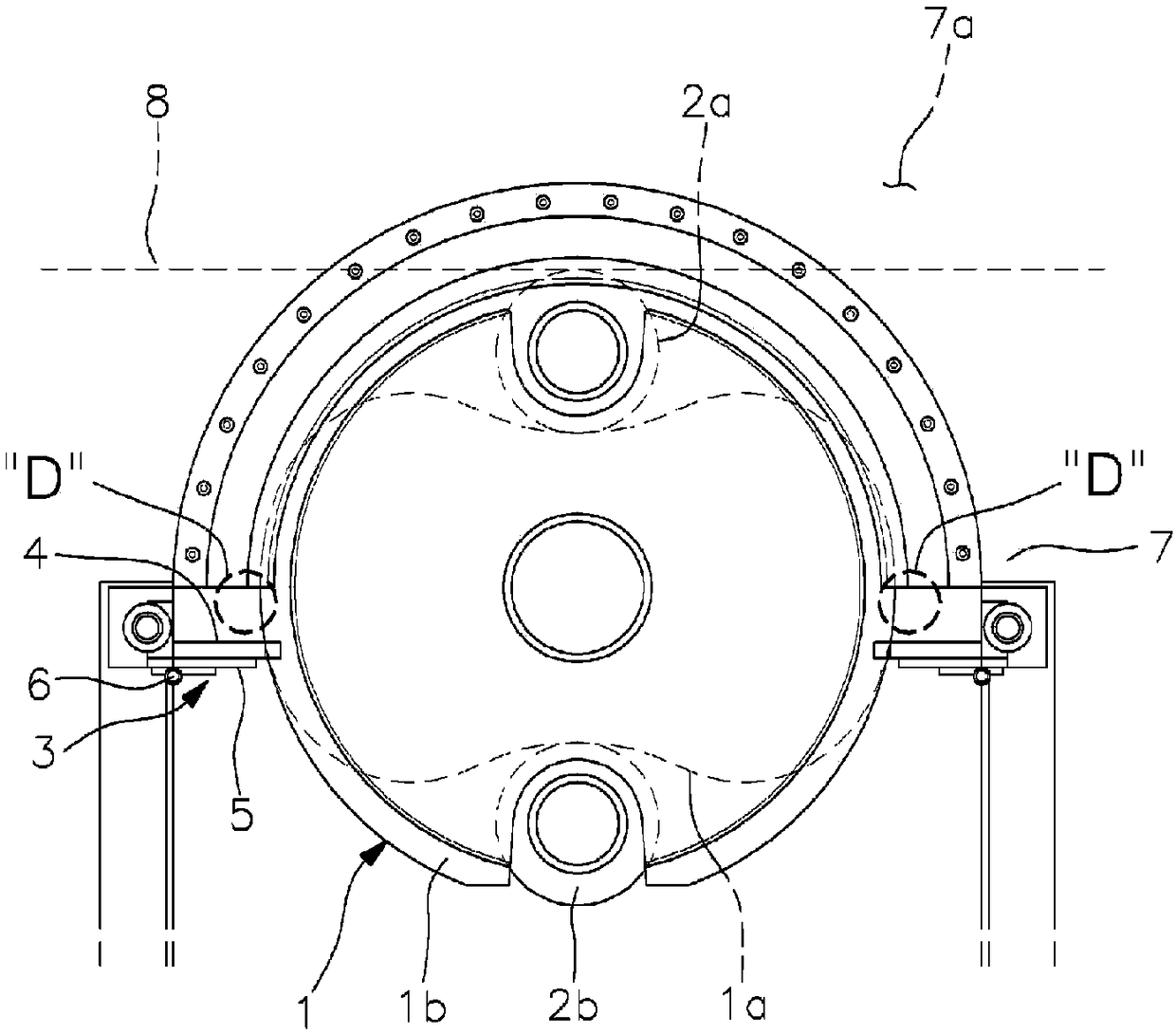

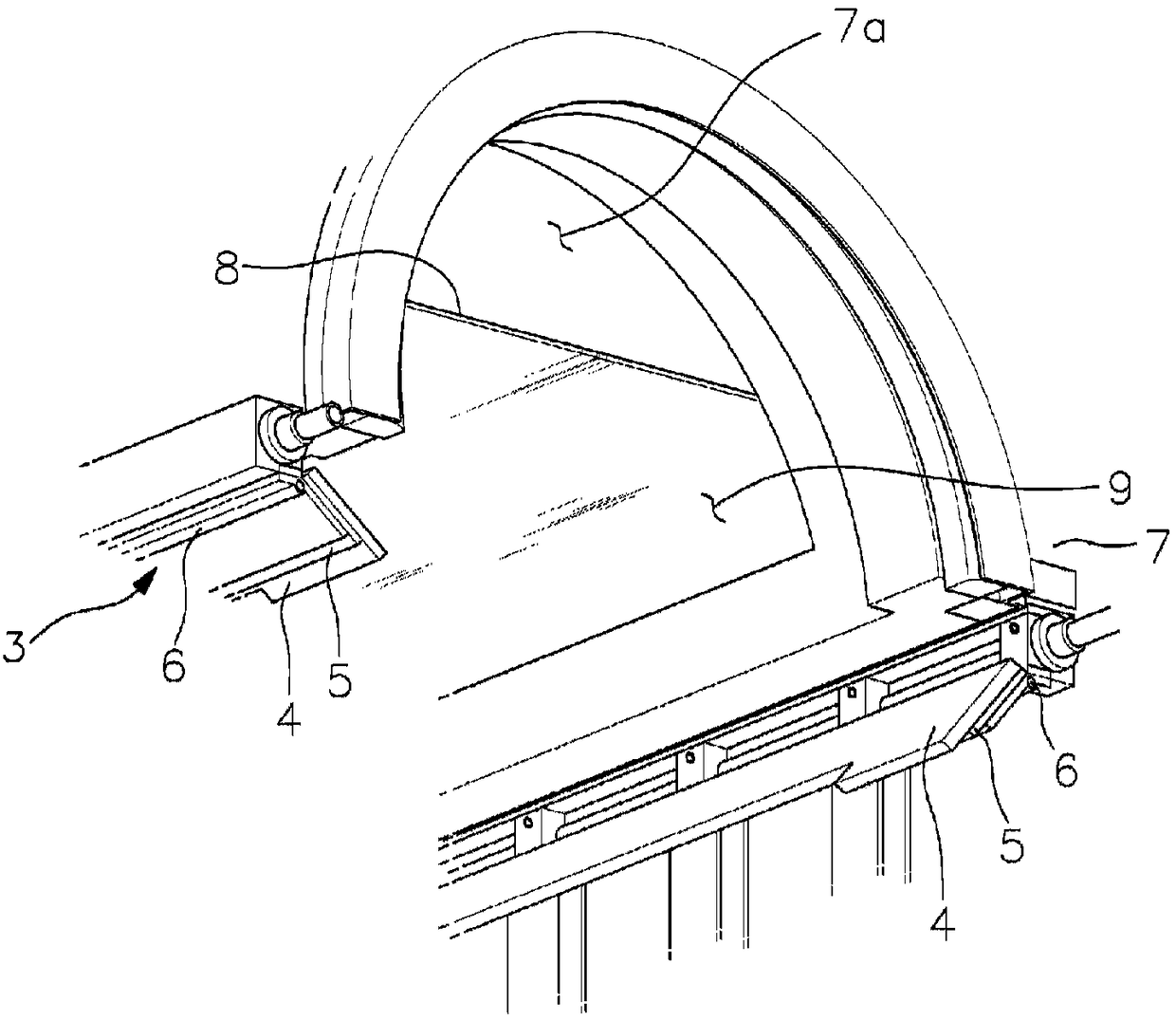

[0056] A first embodiment of the present invention will be described in detail with reference to the drawings.

[0057] Figure 4 is a side structural view illustrating the setting state of the sealing device of the heat treatment furnace provided with the disc roller according to the first embodiment of the present invention; Figure 5 is a plan configuration diagram illustrating an installation state of a sealing device of a heat treatment furnace provided with a disc roll according to a first embodiment of the present invention.

[0058] refer to Figure 4 and Figure 5 , the sealing device 30 is respectively arranged on the furnace wall 70 of the heat treatment furnace on the two sides of the disc roller 10, to prevent hot gas from leaking from the gap between the side of the disc roller 10 and the furnace wall 70 of the heat treatment furnace.

[0059] The inner space 70a of the heat treatment furnace maintains a high temperature, and the steel strips 80 pass through i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com