Air-filling equipment for making foam plastics

A foamed plastics and equipment technology, which is applied to the field of gas filling equipment for foamed plastics production, can solve the problem of difficult to know whether or not enough gas has been added, and achieves the effect of simple operation and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

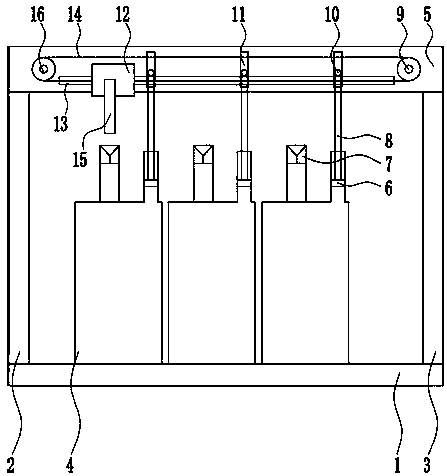

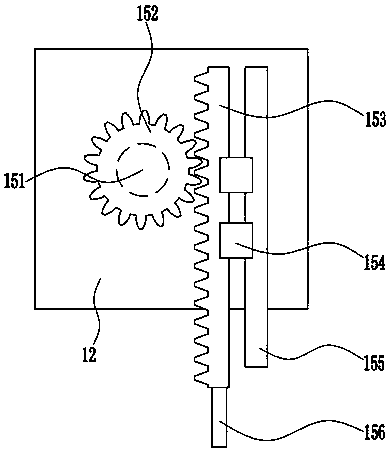

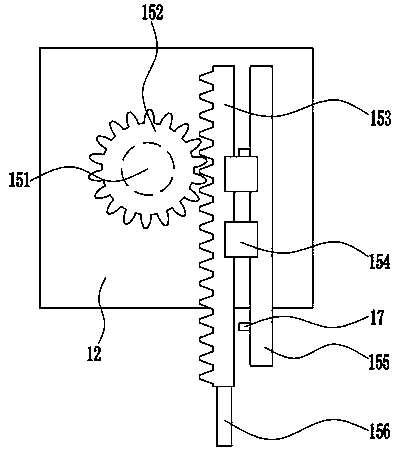

[0028] A kind of air-filling equipment for making foam plastics, such as Figure 1-4 As shown, it includes bottom plate 1, left frame 2, right frame 3, storage tank 4, mounting plate 5, piston 6, rubber plug 7, connecting rod 8, first fixed pulley 9, first travel switch 10, first Slider 12, first slide rail 13, pull wire 14, elevating device 15 and second fixed pulley 16, bottom plate 1 top left side is welded with left frame 2, bottom plate 1 top right side is welded with right frame 3, left frame 2 and right The top of frame 3 is welded with mounting plate 5, evenly has a word hole 11 on the mounting plate 5, and the front side of mounting plate 5 is welded with the first fixed pulley 9 and the second fixed pulley 16 through the bracket left and right symmetry, the first fixed pulley 9 and the second fixed pulley The two fixed pulleys 16 are rotatable, the first fixed pulley 9 and the second fixed pulley 16 are wound with a backguy 14, and the lower part of the front side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com