Embedded wire stator transferring tool

A technology for transferring workers and stators, which is applied in the field of wire-wire stator transfer tooling, can solve the problems of inter-turn short circuit, mutual collision of wire-wire stators, and deformation of the winding ends of wire-wire stators, so as to reduce the frequency of back-and-forth transfers and improve production. Efficiency, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

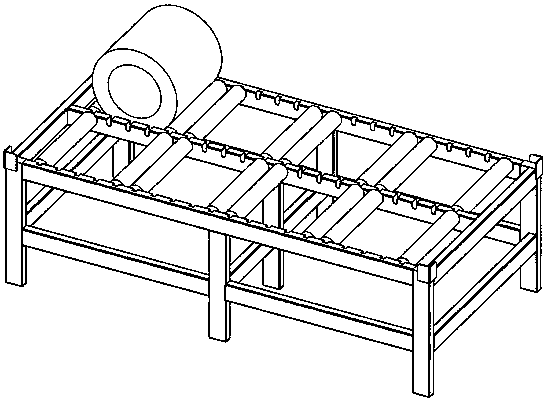

[0010] Such as figure 1 As shown, the present invention comprises integral frame 1, roller 2; Integrated frame 1 is a rectangular frame formed by the welding combination of upright column and cross column, and upright column and cross column adopt carbon steel square pipe to make; On integral frame 1 There are two or three horizontal columns parallel to each other along the length direction on the end surface. figure 1 The middle is set as three, and the three horizontal columns are two of which are respectively arranged on the two long sides of the overall frame 1, one is located in the middle of the two, and the three columns are parallel to each other; between two or three horizontal columns The upper surface is evenly opened with "U"-shaped notches 4, which are used to place and fix the roller 2. The "U"-shaped notches 4 on two or three horizontal columns correspond to each other, so that the rollers placed on them can 2 are parallel to each other; roller 2 is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com