Anti-wave device and working method for floating signal tower

A wave-proof and signal tower technology, applied in the field of signal towers, can solve problems such as threats to equipment and personnel safety, and poor mooring environment, and achieve the effects of convenient installation and transportation, improved mooring environment, and reduced impact on normal operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

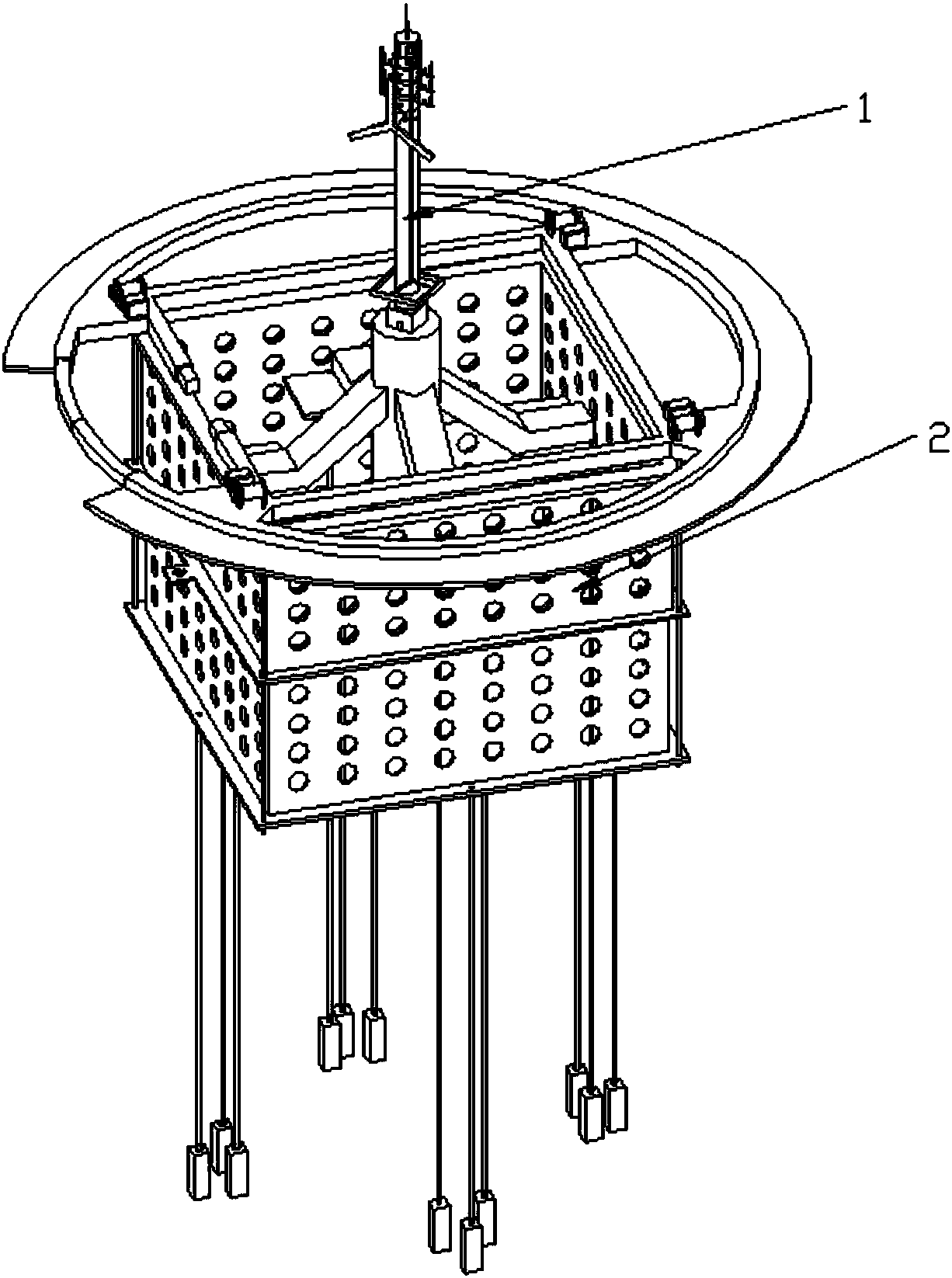

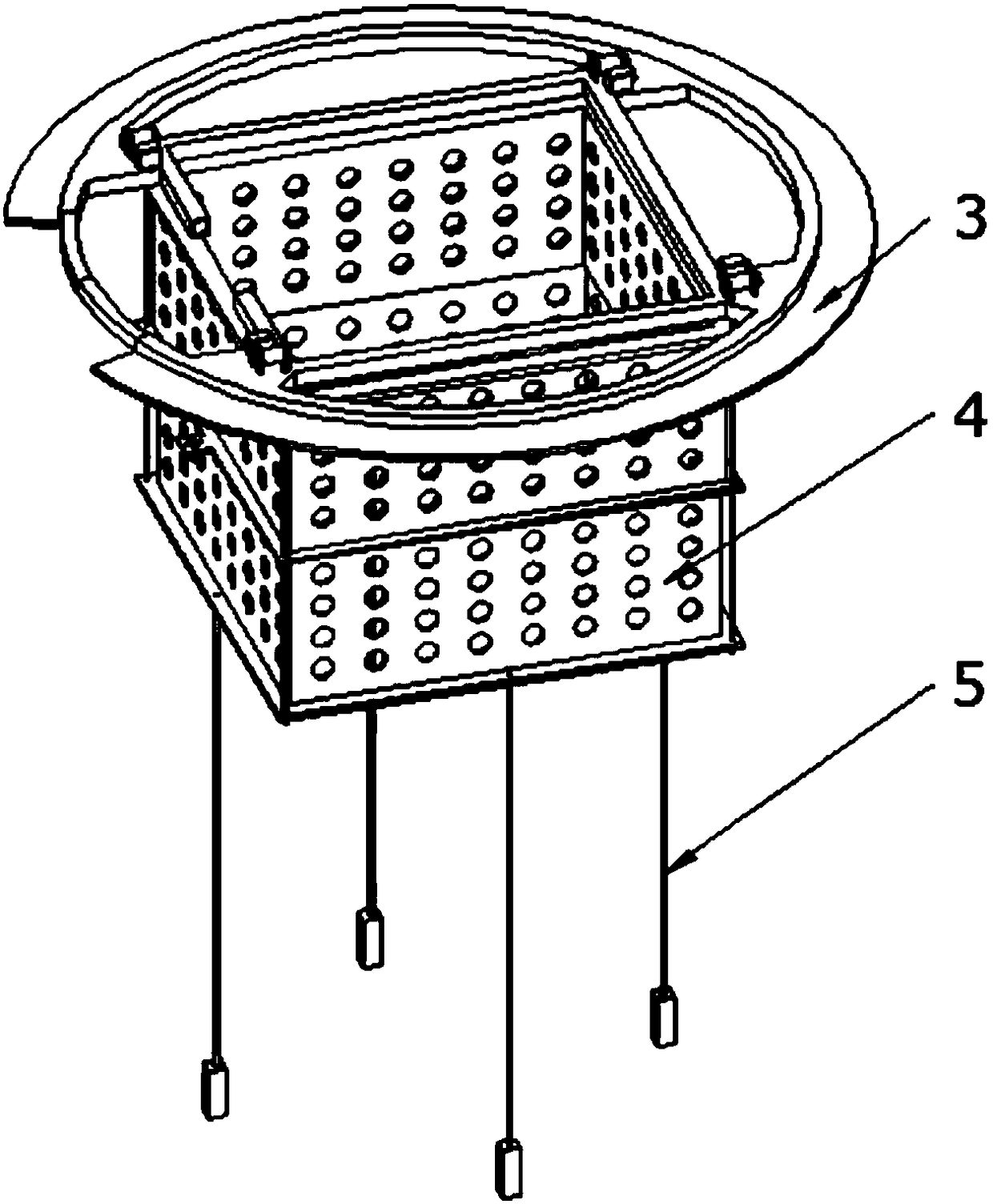

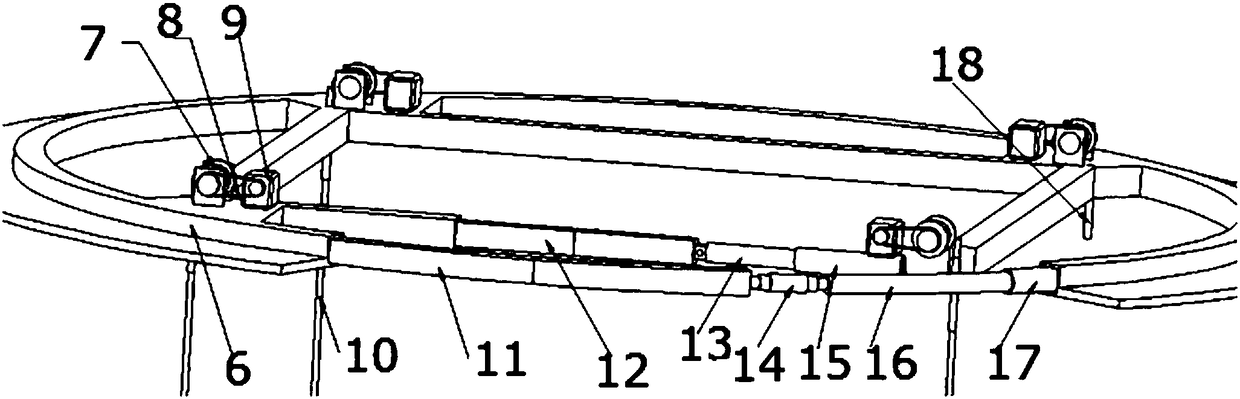

[0039] An anti-wave device for floating signal towers, such as Figure 2.1 As shown, it includes the anti-wave device buoy 3, the anti-wave system 4 and the tension leg system 5 connected sequentially from top to bottom, such as Figure 2.3As shown, the wave-proof tube system 4 includes a primary wave-proof tube 19, a secondary wave-proof tube 22 that can move up and down and is sleeved in the primary wave-proof tube 19, the primary wave-proof tube 19 and the secondary wave-proof tube 22 up and down There is no cover, and several anti-wave holes 23 are provided on the walls of the primary wave-proof barrel 19 and the secondary wave-proof barrel 22 .

[0040] The anti-wave device is arranged on the periphery of the signal tower 1, such as figure 1 As shown, the anti-wave device buoy 3 makes the anti-wave device float on the sea surface, controls the expansion degree of the secondary anti-wave cylinder 22, changes the size of the anti-wave hole 23, controls the flow rate of the...

Embodiment 2

[0054] The working method of the anti-wave device described in embodiment 1, the specific steps include:

[0055] (1) The anti-wave device is transported around the signal tower 1 by a transport ship, the pile anchor 25 is fixed on the seabed, and the anti-wave device is floated around the signal tower 1 by the buoy 6 and the tension leg system 5;

[0056] (2) Control the rotation of the drum 7 through the motor 9, control the movement of the limit screw 21 through the traction rope 10, and control the expansion degree of the secondary anti-wave cylinder 22, so that the anti-wave device can adapt to different working environments;

[0057] (3) When a working ship enters and exits the signal tower 1, the expansion and contraction of the buoy outer retaining ring 11 and the buoy inner retaining ring 12 are respectively controlled by controlling the outer ring hydraulic cylinder 17 and the inner ring hydraulic cylinder telescopic cylinder 15, so that the anti-wave device is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com