Layering-preventing structure for TSOP packing lead frame

A technology of encapsulating leads and layered structures, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of product reliability, poor shrinkage force, and poor stress resistance, so as to ensure vacuum fixation and increase impact. The effect of cutting area, reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

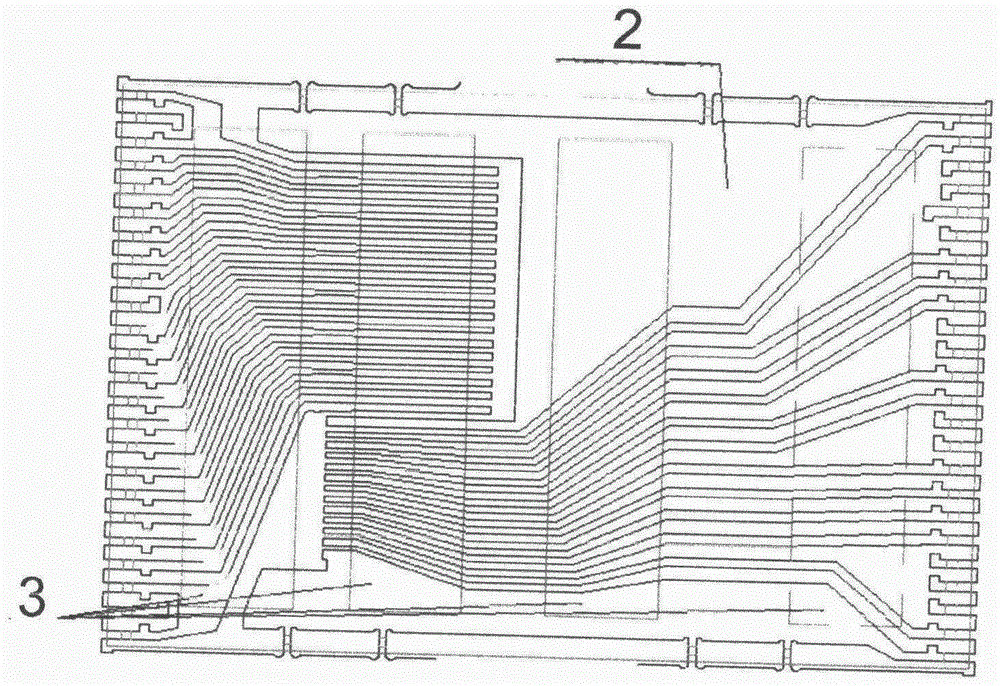

[0014] Such as figure 1 with figure 2 Shown, the contrast of the anti-delamination structure of the TSOP package form lead frame of the present invention and the existing layered structure is: the large-area copper sheet area (such as figure 1 As shown), it can be well absorbed by the suction plate of the wire bonding machine, but it will cause the problem of delamination in the injection molding. The body produces a large stress difference due to different shrinkage rates, resulting in delamination (such as figure 2 shown).

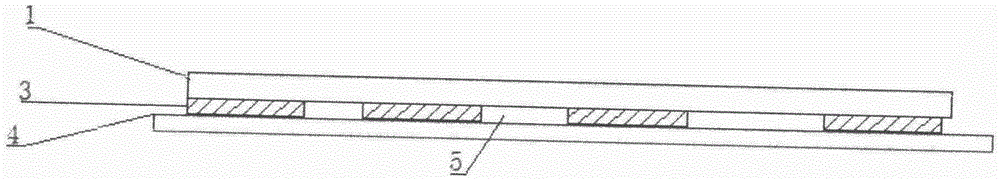

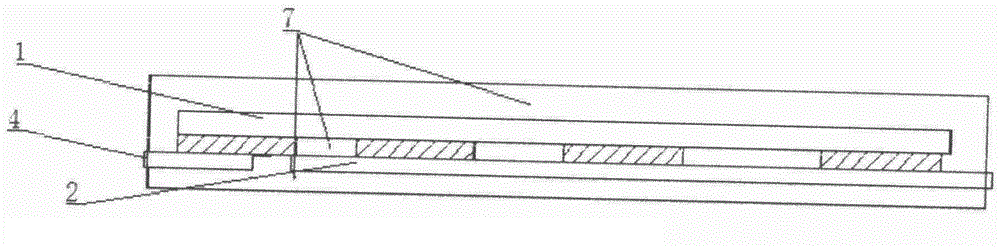

[0015] Such as image 3 with Figure 4 As shown, the TSOP package lead frame anti-delamination structure of the present invention includes wafer IC1, adhesive tape 3, lead frame 4 and floating area 5, and a large-area copper area 2 is provided on the lead frame below the wafer IC1 position , the wafer IC1 is covered with adhesive tape 3, the suspended area 4 is arranged between the adhesive tapes 3, the lead frame 4 is arranged on the bottom surfa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap