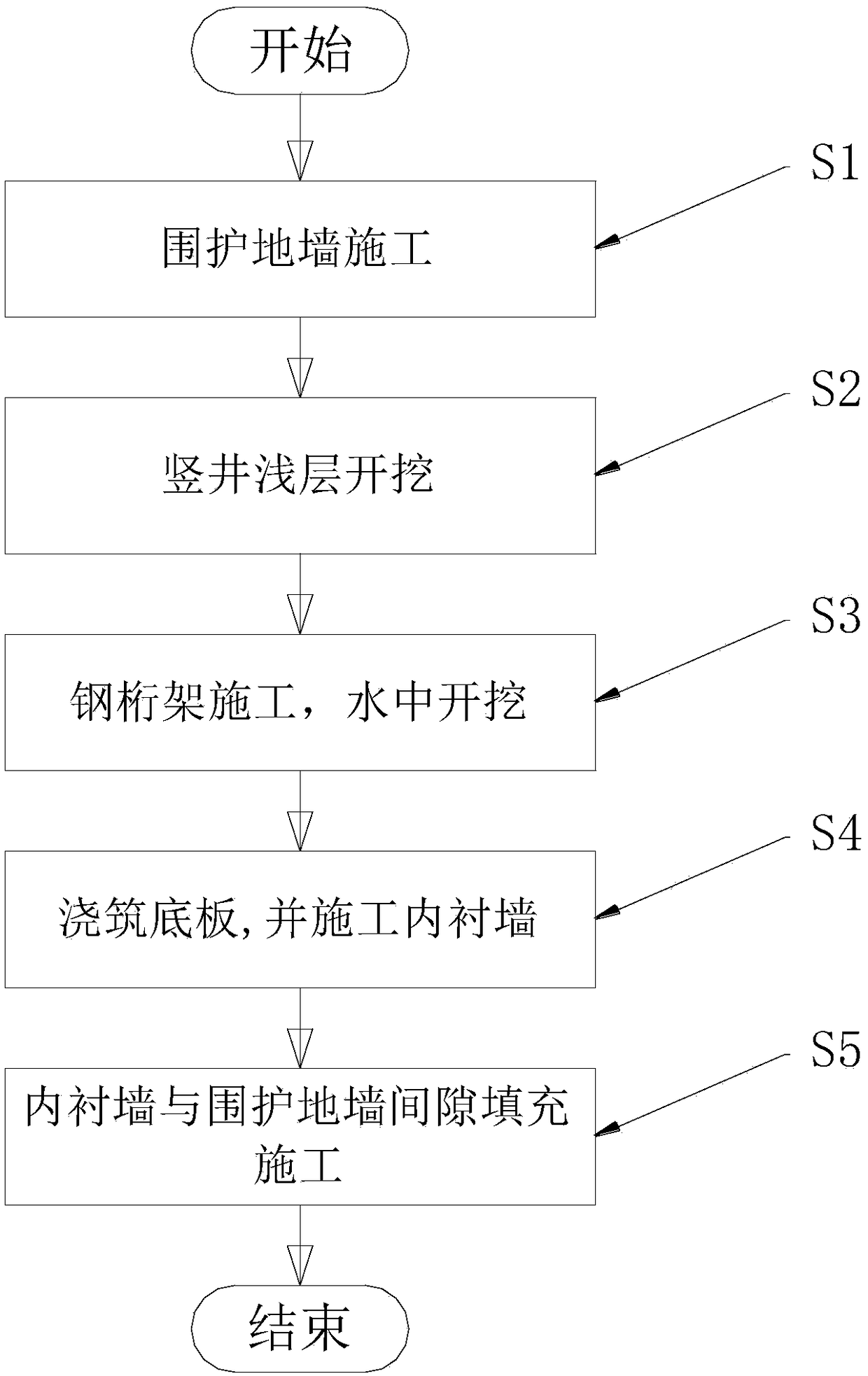

A construction method for shaft excavation

A construction method and shaft technology, which are applied in the field of shaft excavation construction and ultra-deep shaft engineering construction, can solve problems such as anti-floating and impact of shaft bottom plates, and achieve the effects of shortening construction depth, improving construction efficiency and reliable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

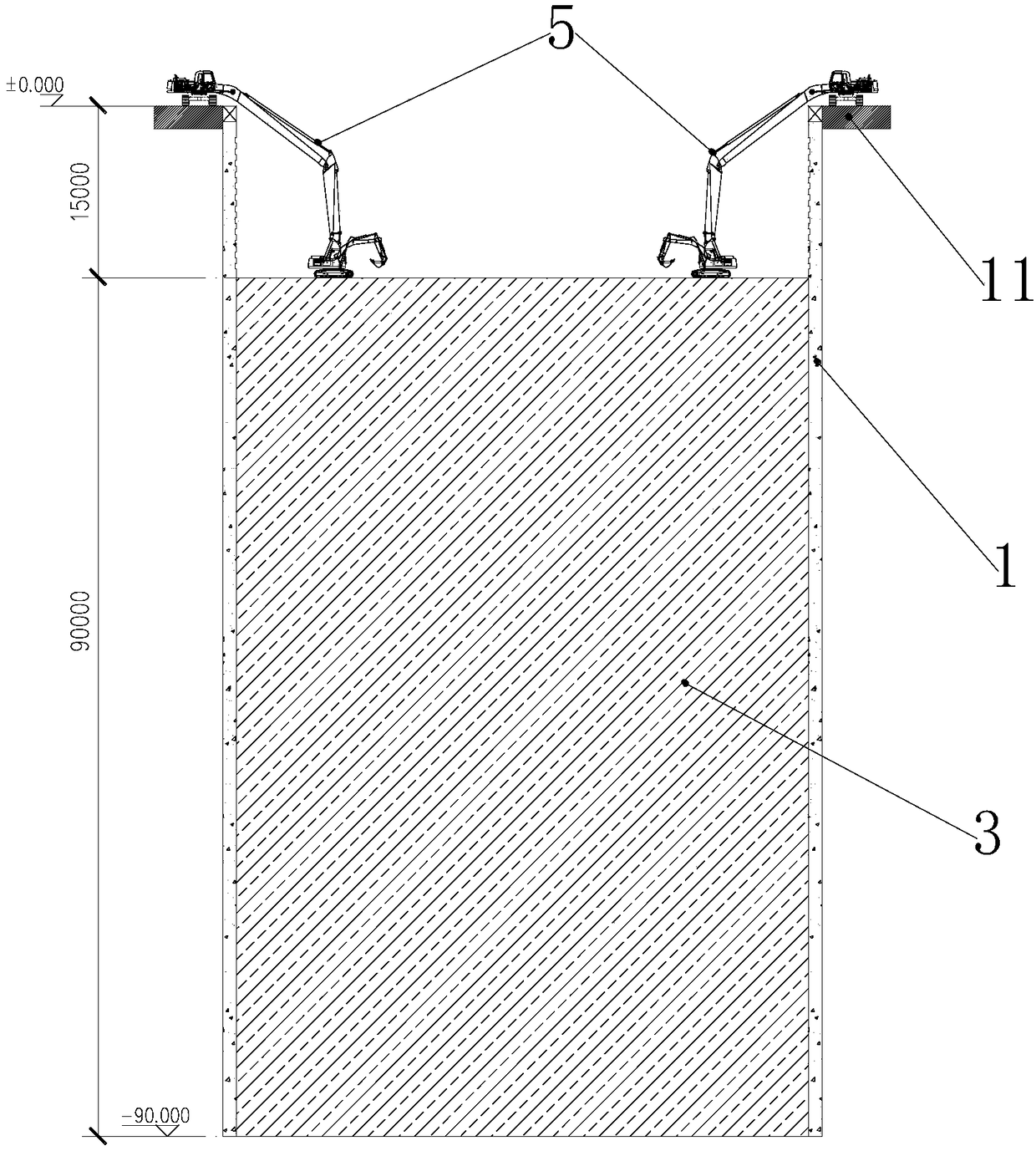

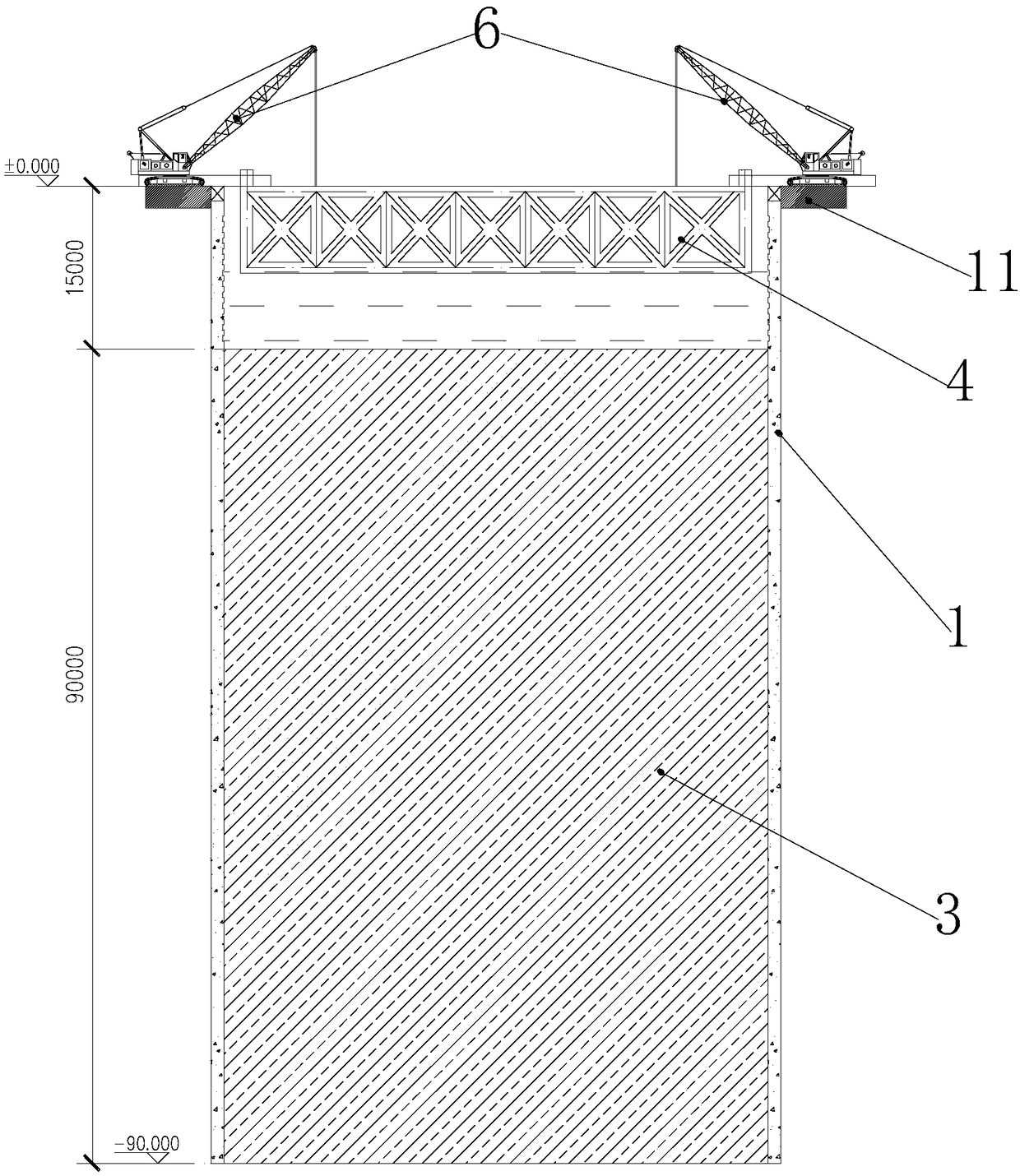

[0042] The core idea of this application is: in the construction process of the ultra-deep shaft structure, the construction method of not lowering the deep confined water is adopted, and at the same time relying on the buoyancy of the water and combining the lifting equipment to construct the lining wall of the shaft, the construction efficiency is improved, the quality is reliable, and the problem is solved. The water pressure inside and outside the foundation pit of the shaft is balanced, which has little impact on the surrounding environment of the shaft; secondly, fill in sections between the enclosure wall and the lining wall, and set up shear keys at local locations to solve the problem of common problems between the bottom plate of the ultra-deep shaft and the support structure. Stress problem.

[0043] The shaft excavation construction method proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com