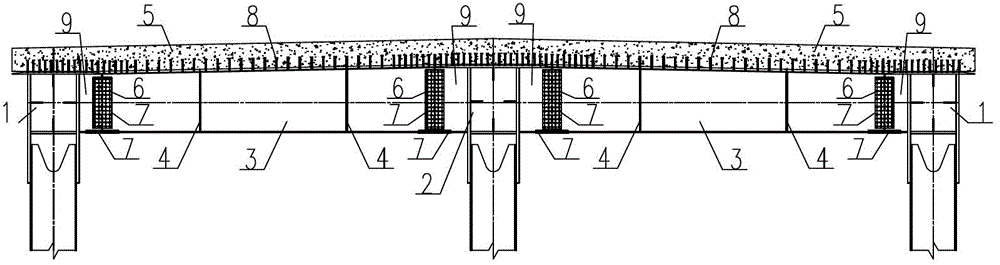

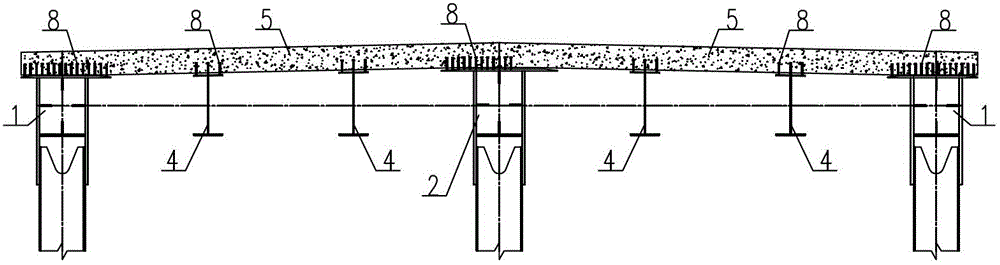

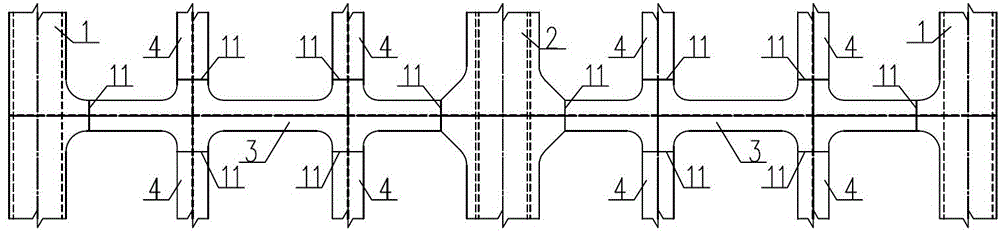

Composite structure of three main trusses, longitudinal beams, transverse beams and concrete slabs

A technology of concrete slab and composite structure, which is applied in the direction of bridges, truss bridges, bridge parts, etc., to achieve the effect of durable structure, simple construction, and solving the problem of bridge deck paving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The side girders constituting the three main girders of the present invention, the top plate, the bottom plate and the vertical plates on both sides of the girder are welded into one body, and its cross section is box-shaped.

[0015] The top plate, web plate and bottom plate of the steel longitudinal beam are welded as a whole, and the longitudinal beam joint 10 at the steel longitudinal beam and the steel cross beam are bolted and welded as a whole (see Figure 5 ). The top plate, web plate and bottom plate of the steel beam are welded as a whole, and the beam is bolted and welded together with the beam joint 9 at the node of the center truss and side truss (see figure 1 ).

[0016] The concrete slab is a reinforced concrete structure, and the concrete slab is combined with the side girder 1, the middle girder 2, the steel beam 3 and the steel longitudinal beam 4 through the shear key 8.

[0017] Specific embodiments of the present invention will be described in det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com