Electric lifting table

An electric technology for lifting tables, which is applied in the field of lifting tables, can solve the problems of easy oil removal, product stability and service life, sliding friction parts falling off, etc., and achieve the effect of ensuring the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

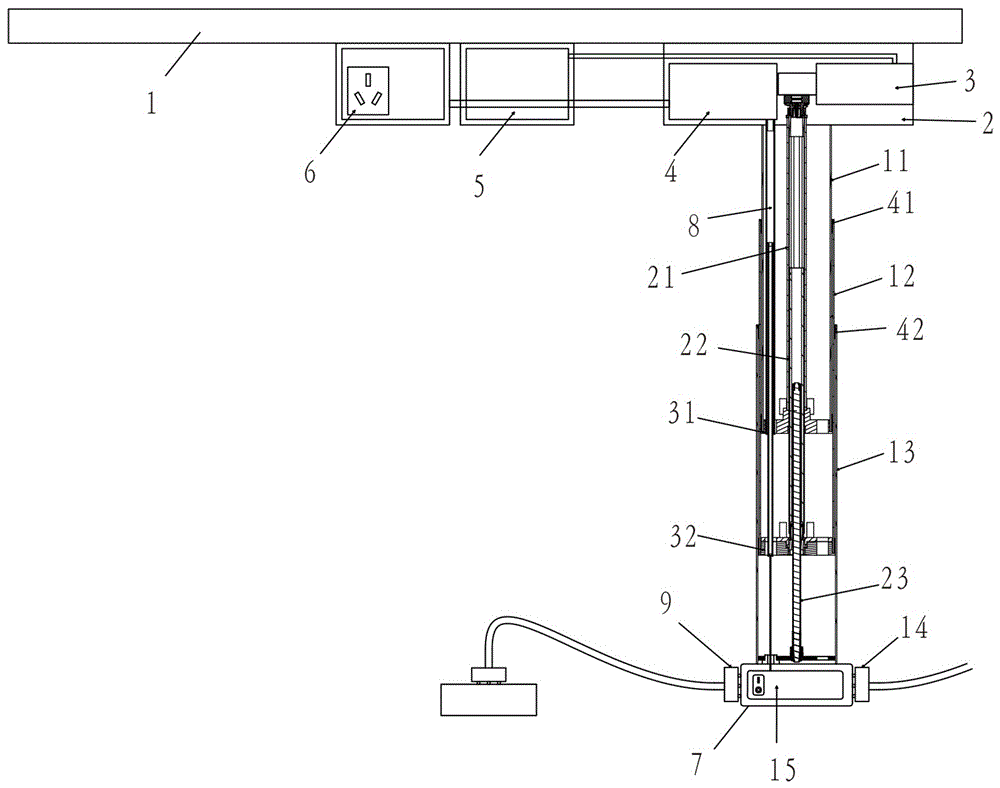

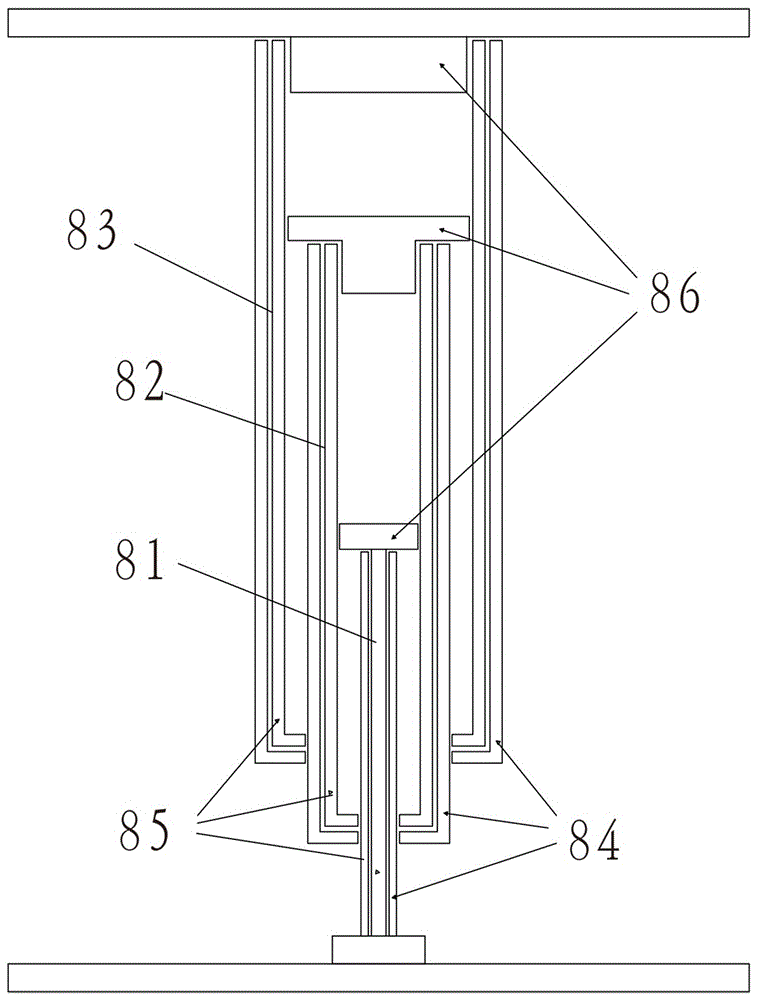

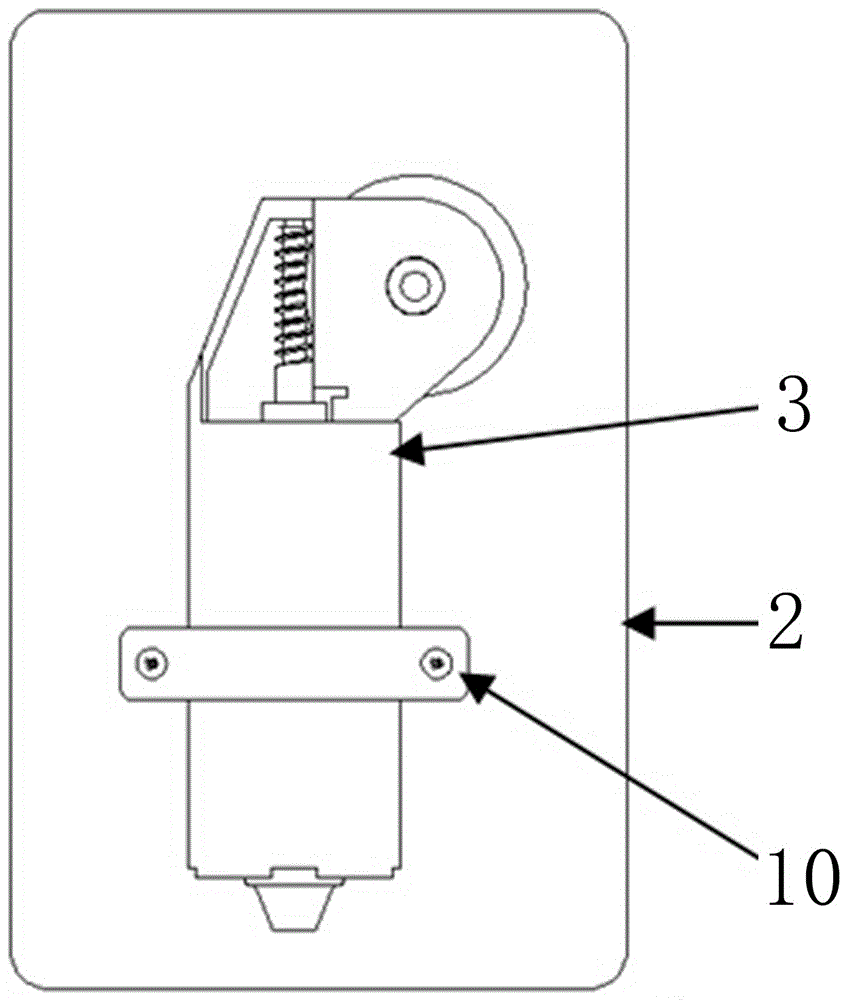

[0024] See attached picture. This embodiment comprises desktop 1 and the lifting table leg that is installed under the desktop, motor box 2 is installed under described desktop, and lifting motor 3 and power controller 4 are installed in motor box 2; Motor is also installed under described desktop 1 The controller 5 and the AC socket 6; the lifting table leg is a hollow structure, and a base 7 is provided under the lifting table leg; the lifting table leg is composed of an inner tube 11, a middle tube 12 and an outer tube 13, and the outer tube 13 is set in the middle tube 12, the middle tube 12 is set outside the inner tube 11; the bottom of the outer tube 13 is fixed on the base 7, and the top of the inner tube 11 is fixed on the desktop 1; the lifting table leg is provided with a conductive rail 8, and the lifting table leg The base 7 below is provided with a power input interface 9, the bottom end of the conductive rail 8 is fixed on the base 7, and is electrically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com