An ultrasonic motor with multi-stator planar array structure

An ultrasonic motor, planar array technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. The effect of improving friction driving ability, high electromechanical conversion efficiency, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

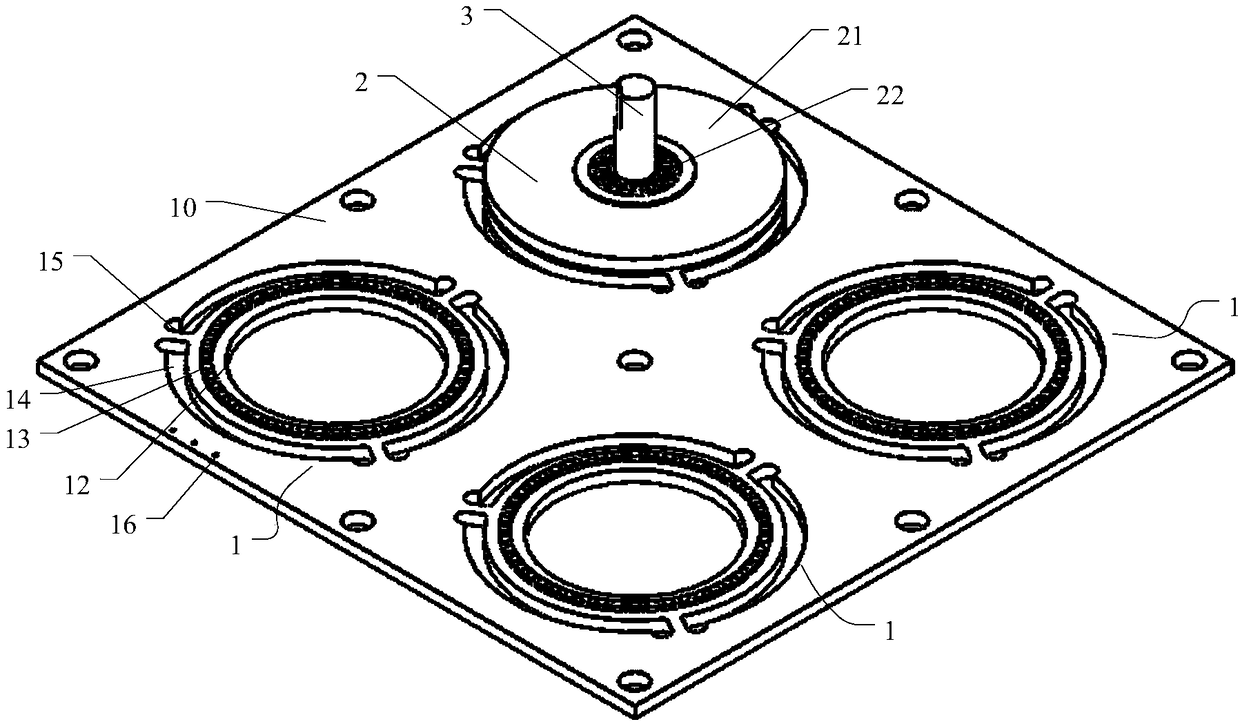

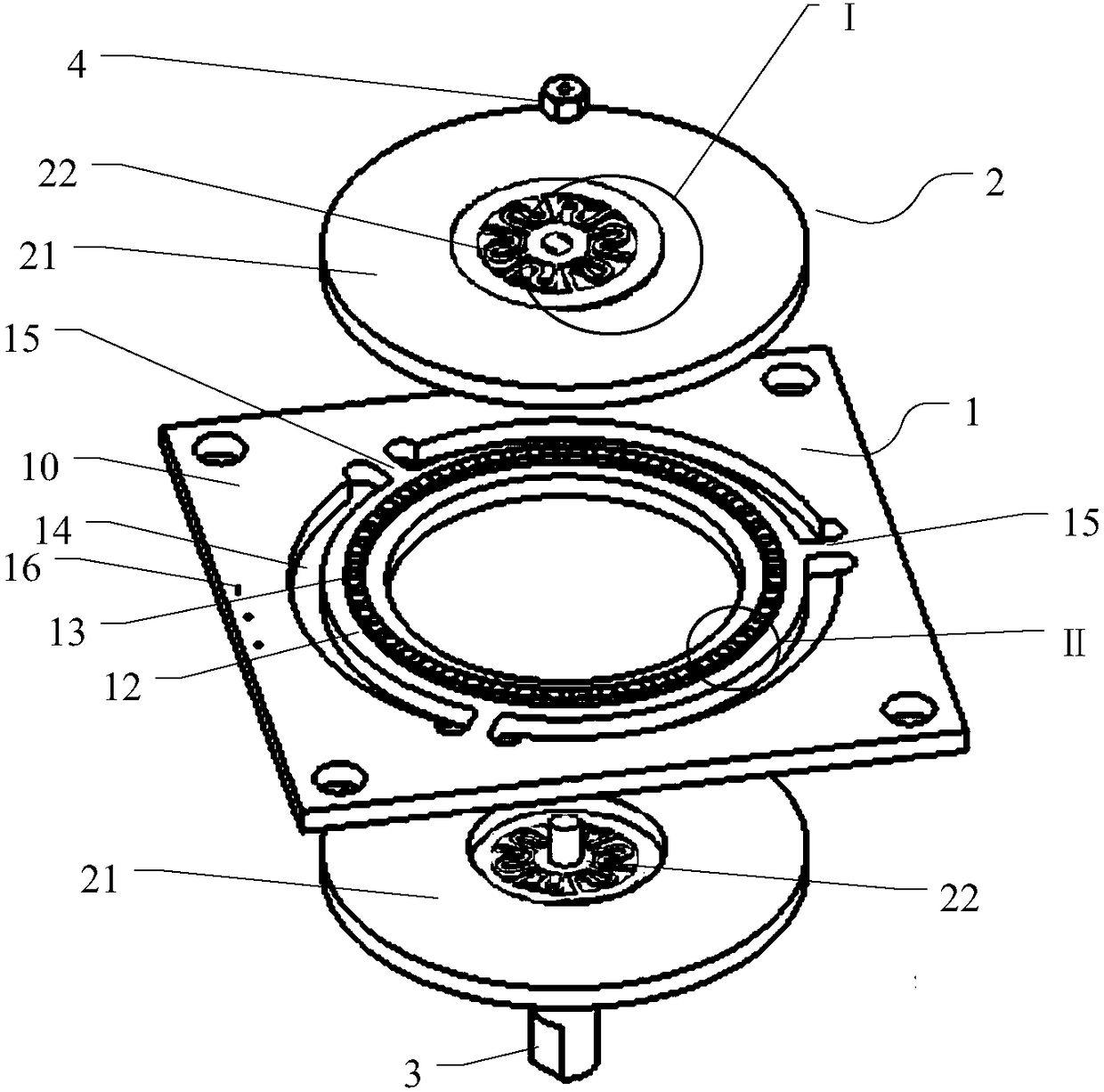

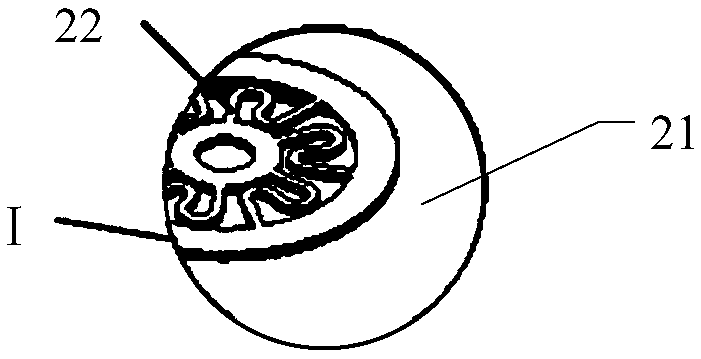

[0053] like Figure 1~Figure 4 As shown, an ultrasonic motor with a multi-stator planar array structure includes a stator 1, a rotor 2 and an output shaft 3. The ultrasonic motor with a multi-stator planar array structure includes a stator plate 10, and the stator plate 10 is provided with at least Two stators 1, each corresponding to two rotors 2; the stator 1 includes a hollow stator ring 12 and a piezoelectric ceramic module, the stator ring 12 is provided with annularly distributed welding pads, and the piezoelectric ceramic module Including N piezoelectric ceramic elements 13, the piezoelectric ceramic elements 13 are welded and fixed on the pads of the stator ring 12, wherein, N is a multiple of 8; between the stator ring 12 and the stator plate 10, a stator The ring 12 vibrates in the gap 14, and the stator ring 12 is connected with the stator plate 10 through a support connecting hinge 15; the stator plate 10 is also provided with driving electrodes, and the electrodes...

Embodiment 2

[0063] On the basis of Embodiment 1, this embodiment is different from Embodiment 1 in that it adopts a four-phase driving method, and the arrangement rule and signal connection mode of the piezoelectric ceramic elements 13 on the stator ring 12 on the pads are different from Embodiment 1. Specifically:

[0064] like Image 6As shown, the piezoelectric ceramic element 13 and the electrodes include 4 groups of standing wave drive units, which are respectively unit a, unit b, unit c and unit d, and each unit includes two piezoelectric ceramic elements on the front side of the stator ring 12 13 and two piezoelectric ceramic elements 13 on the opposite side of the stator ring 12, the piezoelectric ceramic elements 13 are arranged in sequence according to unit a, unit b, unit c, and unit d, and are arranged circularly on the front and back sides of the stator ring 12;

[0065] In the unit a, unit b, unit c, and unit d, the polarized positive poles 131 of the two piezoelectric cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com