Back cover plate equipped with locking mechanism for railway train communication equipment, and use method for back cover plate

A technology of train communication and locking mechanism, which is applied in the direction of electrical equipment casing/cabinet/drawer, casing/cabinet/drawer parts, electrical components, etc. Problems such as the number of plates and structural parts, etc., to achieve the effect of satisfying the reliability of use, and the convenience and speed of installation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

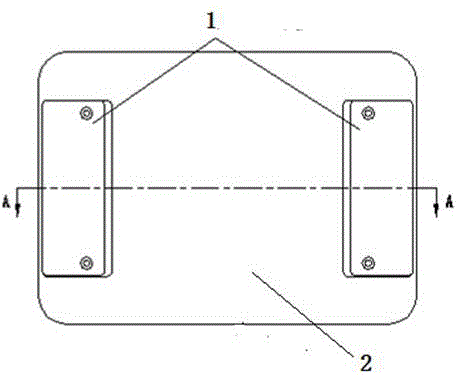

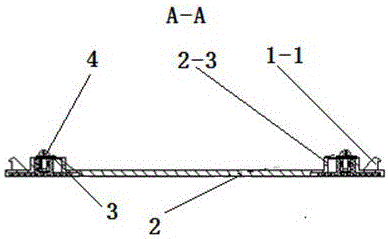

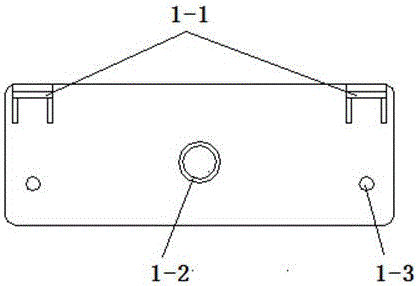

[0014] like Figure 1~7 As shown, buckle 1 is an injection molded part, and the material is engineering plastics. There are hooks 1-1, internal threaded columns 1-2, fixing holes 1-3, and rear cover plate 2 on the buckle 1, which are matched with the front shell of the equipment. It is a machine-added part, made of aluminum alloy, with two grooves 2-1 that match the buckle 1, four hook holes 2-2, and two internal thread column oblong holes 2-3 with bosses. And four threaded holes 2-4, the anti-loosening gasket is machined, and the material is galvanized steel; two buckles 1 are placed on the groove 2-1 of the rear cover 2, and the four hooks 1 of the buckle 1 -1 is inserted into the four hook via holes 2-2 of the back cover 2, and two internally threaded columns 1-2 are inserted into the two internally threaded column oblong via holes 2-3, and the internally threaded columns 1-2 are higher than the back cover The surface of the plate 2 is 0.15 mm, and the two screws 4 are eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com