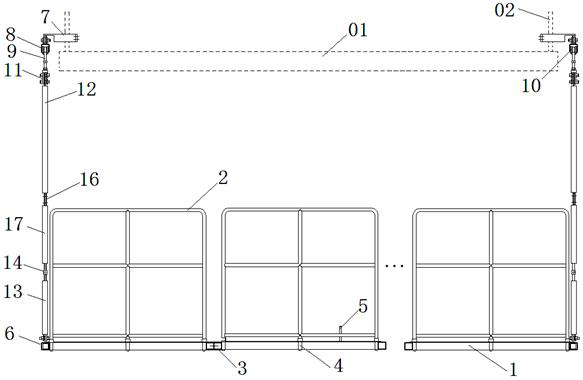

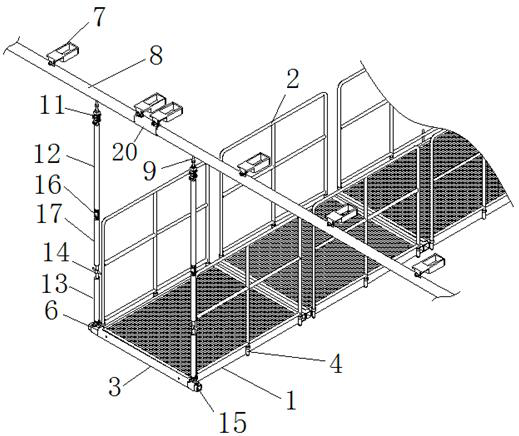

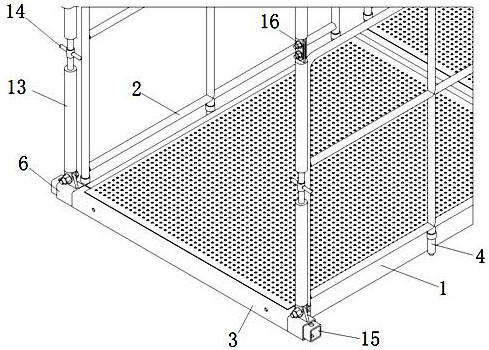

Light movable assembled bridge maintenance hanging basket

A mobile, lightweight technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of occupying bridge deck space, time-consuming and labor-intensive splicing, complex structure, etc., and achieve the effect of convenient use and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] According to the construction requirements, the present invention selects an operation starting area on the bridge surface. According to the width of the bridge deck, a number of modular walking decks 1 are selected according to the starting point of the bridge deck construction work, and placed on the flat ground or floating platform under the bridge deck. The modular walking platforms 1 are spliced together through the through-hole alignment bolts on the side connecting rods 3 to form an overall hanging platform platform for maintenance bridges (such as figure 1 and figure 2 shown). The outer side of the walking platform 1 in the middle part of the hanging platform platform is installed with a hook 5 (such as figure 1 shown), used to fix the safety rope and tie the other end of the safety rope to the railing of the bridge deck, or to tow the mobile gondola platform. The lower end of the frame-shaped guardrail 2 is inserted into the socket 4 provided on the two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com