Burnish molding tool

A molding tooling and workbench technology, applied in the field of extrusion molding tooling, can solve the problems of slow work efficiency, high scrap rate, high processing cost, etc., achieve high production efficiency, high positioning accuracy, and avoid hard impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

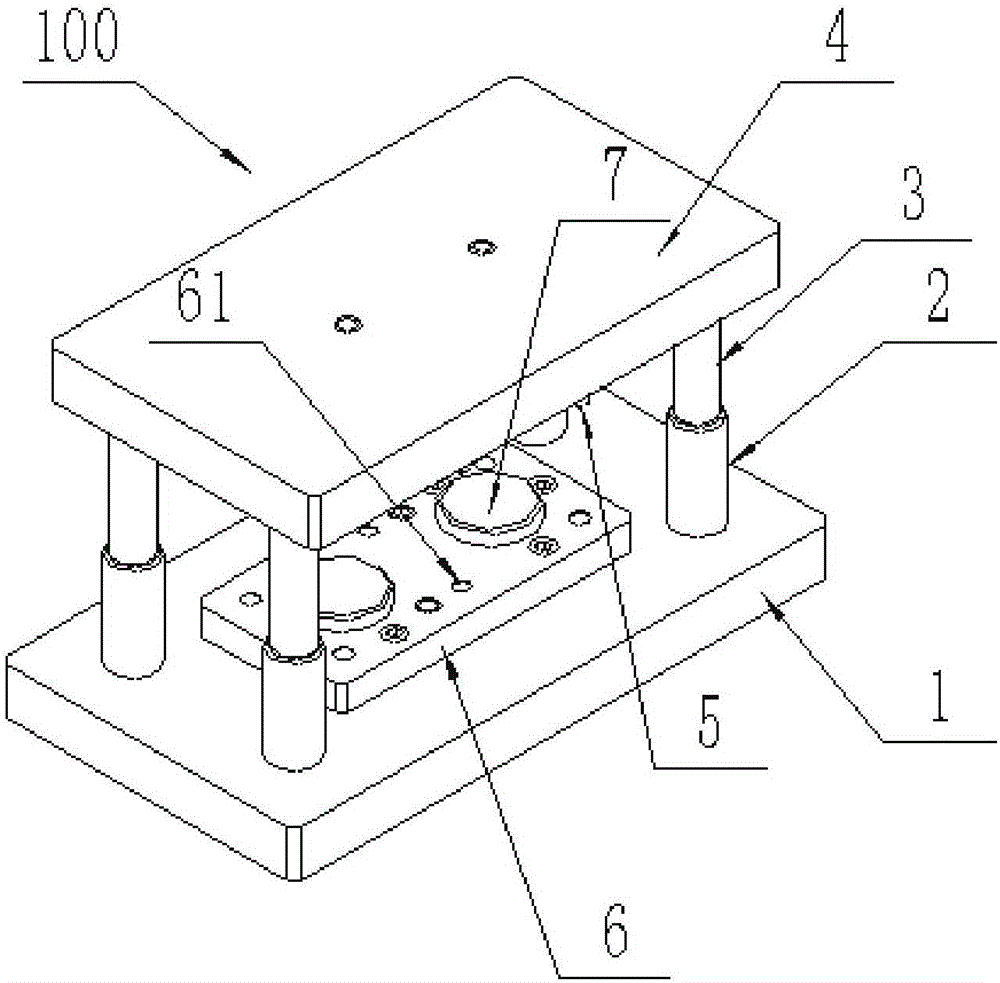

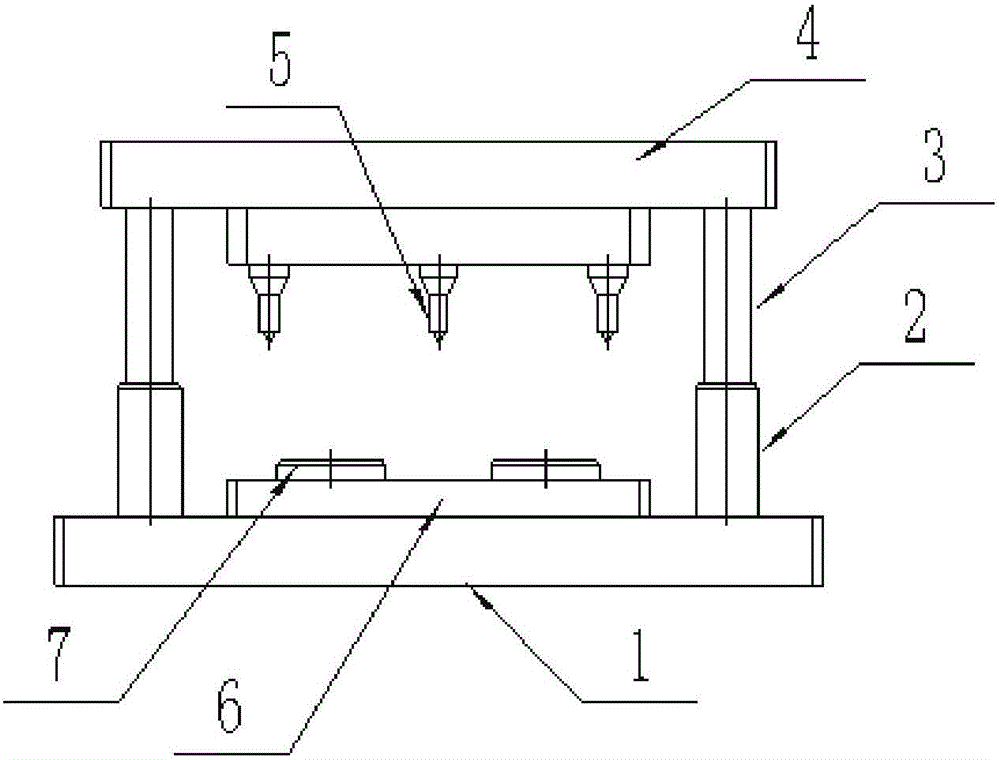

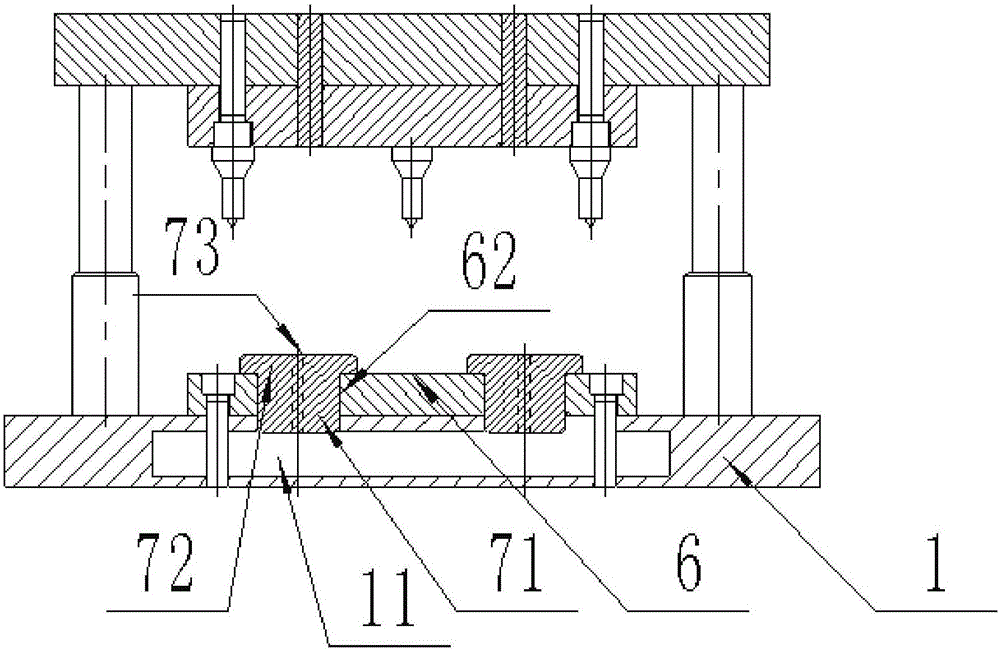

[0025] see Figure 1-2 , the extrusion molding tooling 100 of the present invention includes a base 1, a guide sleeve 2, a guide column 3, a pressing block 4 and a thimble 5, the base 1 is used to support the processing parts, and the guide sleeve 2 is fixedly installed on the base 1 , the pressing block 4 is connected above the guide column 3 , the guiding column 3 slides up and down along the guide sleeve 2 , and the thimble 5 is installed on the pressing block 4 for punching the extrusion hammer 200 .

[0026] Such as Figure 5-6 As shown, the squeeze hammer 200 is used to process the hole 301 on the part 300. The squeeze hammer 200 includes a cylinder 201 and an extrusion ring 202 located in the middle of the cylinder 201 and processed integr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap