Heating type industrial aluminum profile extrusion die

A technology for extruding dies and aluminum profiles, applied in the direction of metal extrusion dies, etc., which can solve the problems of increased weight of the protruding end, bending of the profile at the extruded part of the die, and low yield rate, so as to avoid bending and breaking of the profile and extrude Rapid prototyping and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

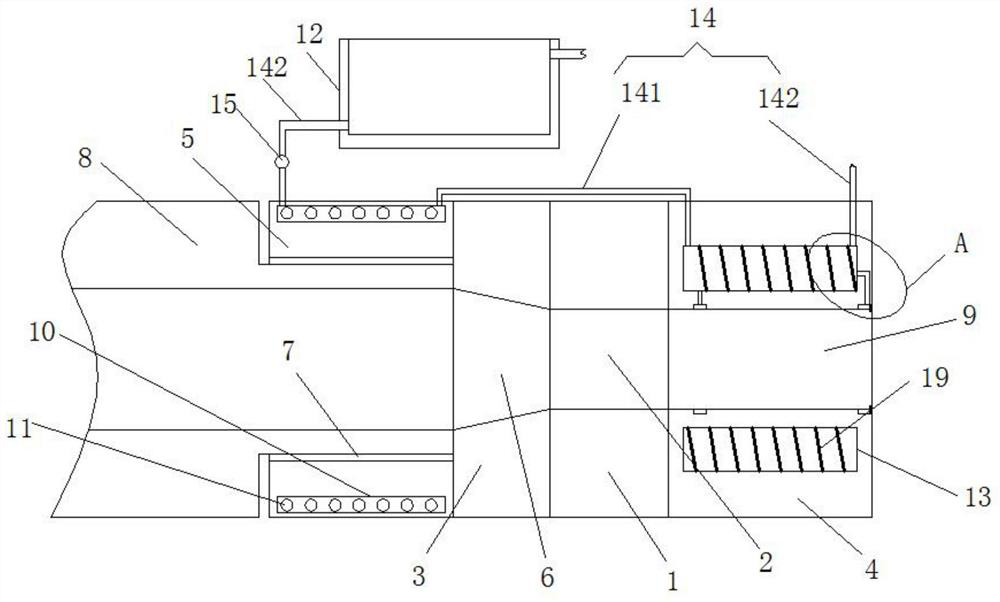

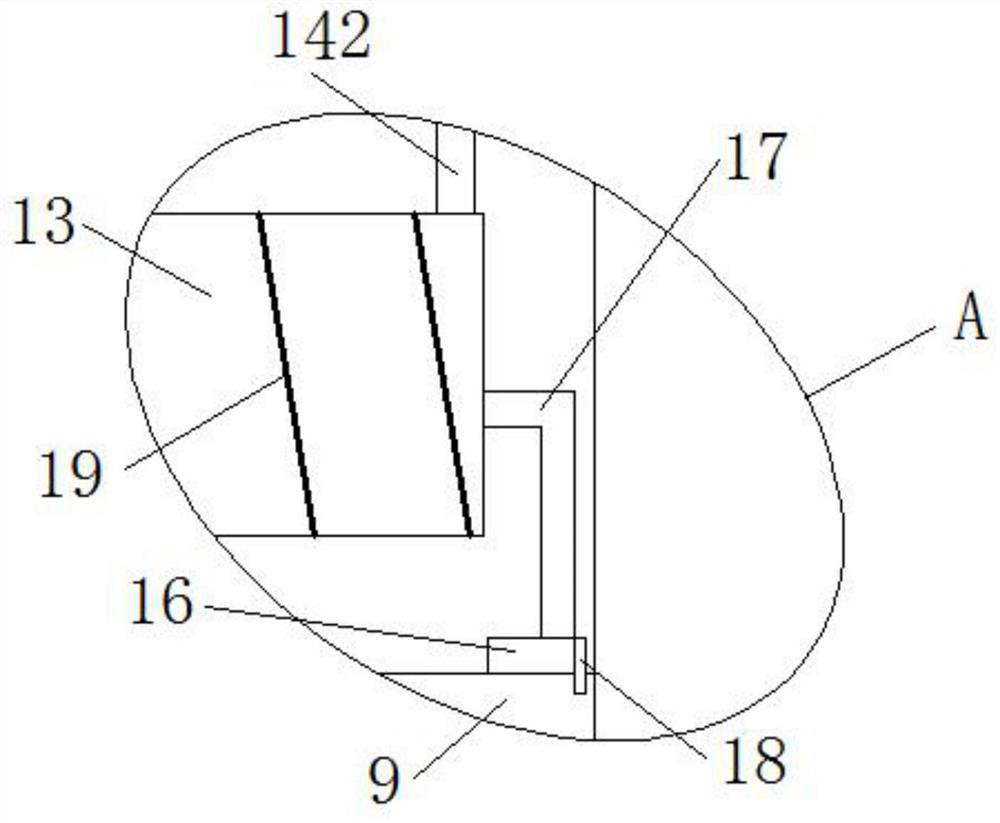

[0018] Such as Figure 1-2 As shown, a heated industrial aluminum profile extrusion die described in this embodiment includes a die body 1, a die groove 2 is opened on the die body 1, and guides are coaxially arranged on both sides of the die body 1. Section 3 and lead-out section 4, the side of the guide section 3 away from the mold body 1 is coaxially provided with a heating section 5, the mold body 1, guide section 3, lead-out section 4 and heating section 5 are integrally structured, the The guide section 3 is provided with a diversion groove 6, and the diversion groove 6 is connected to the mold groove 2, and the heating section 5 is provided with a socket 7 coaxial with the mold body 1, and the socket 7 is connected to the diversion groove 6. The extruded tube 8 is inserted into the socket 7, and the extruded tube 8 inserted in the socket 7 communicates with the diversion groove 6. The export section 4 is provided with an export hole 9, and the outlet hole 9 The shape i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap