A multifunctional fiber laying head

A fiber laying and multi-functional technology is applied in the field of fiber laying equipment to simplify the refeed mechanism, improve the efficiency of the guide wire, and avoid stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in detail below with reference to the drawings and embodiments.

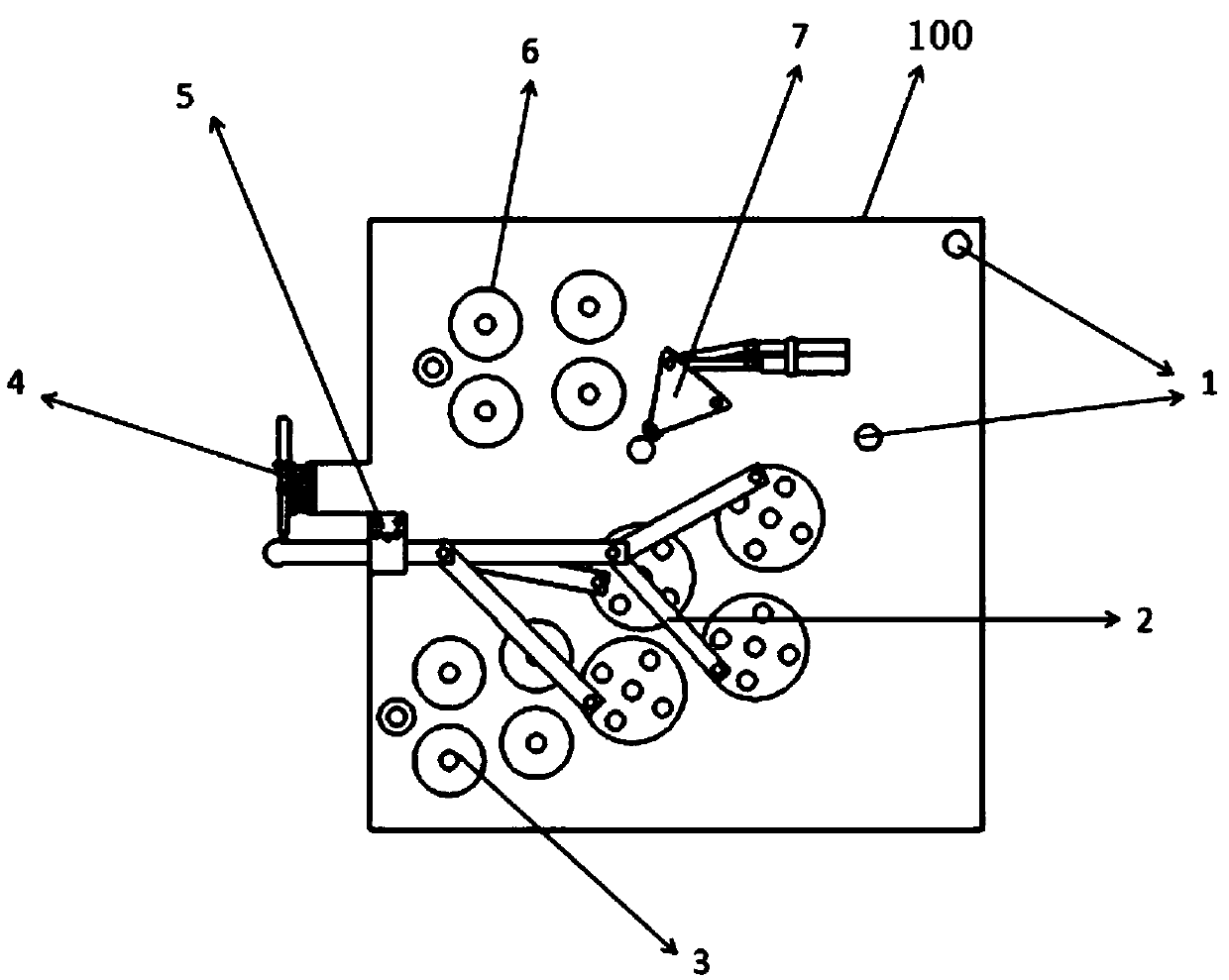

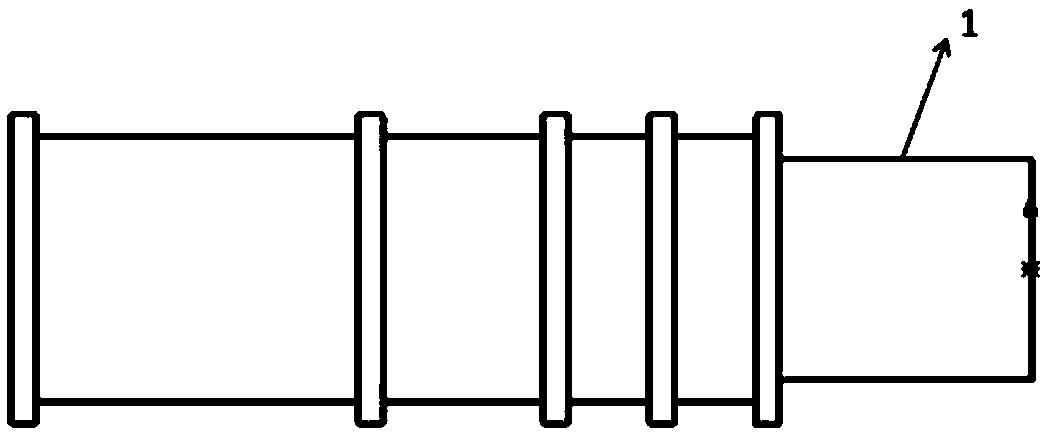

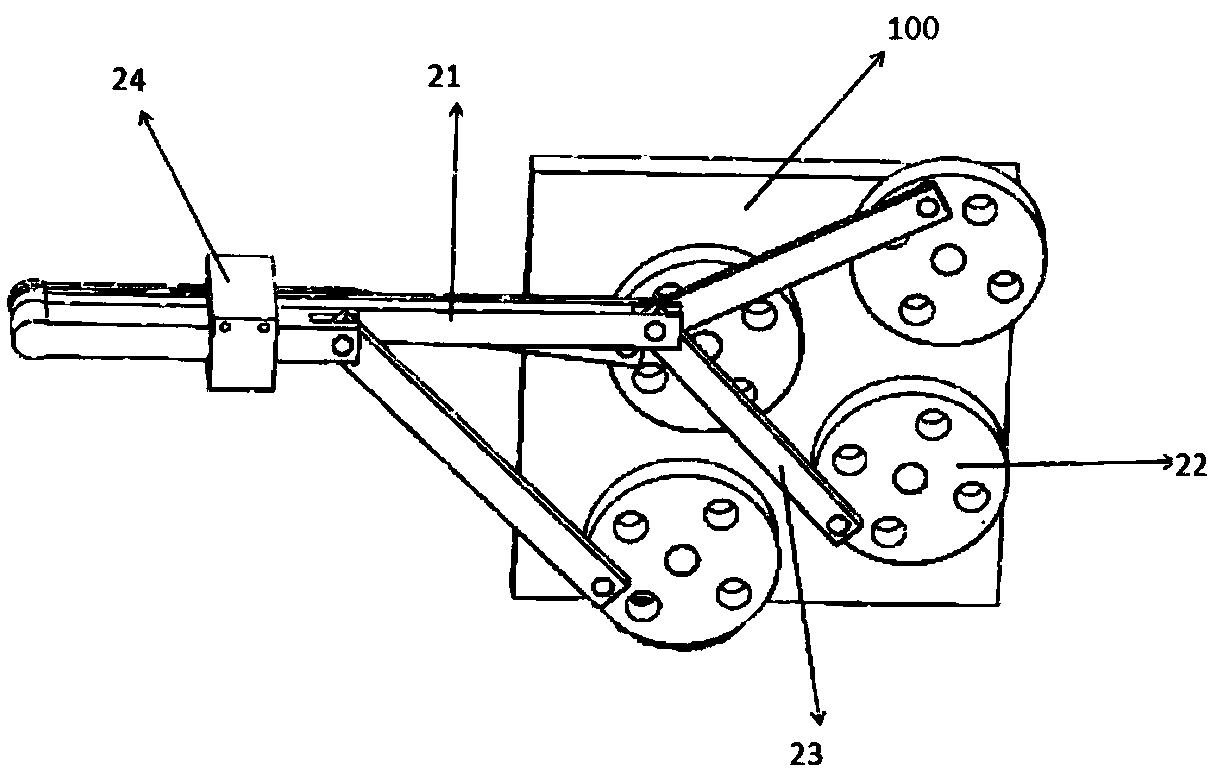

[0035] Reference figure 1 As shown, the multifunctional fiber placement head according to the embodiment of the present invention includes a guide roller mechanism 1, a re-feeding mechanism 7, a heating mechanism 5, an upper backing paper recycling mechanism 6, a shearing mechanism 4, The pressure roller mechanism 2 and the lower backing paper recovery mechanism 3, the guide roller mechanism 1 is used to pass the fiber tape into the placement head, the fiber tape passes through the guide roller mechanism 1 in the placement head to the refeeding mechanism 7, and then passes through the heating mechanism 5. , And then under the interaction of the upper backing paper recovery mechanism 6, the lower backing paper recovery mechanism 3 and the pressure roller mechanism 2, compactly laid on the core mold; the shearing mechanism 4 is set near the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com