Yarn guide transmission mechanism for chemical fiber production

A technology of transmission mechanism and guide wire, which is applied in the direction of filament production, textiles and papermaking, etc. It can solve the problems of inability to meet the demand of chemical fibers, low efficiency of guide wire transmission, increase of production labor force, etc., and achieve reduction of production labor force and novel structure , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

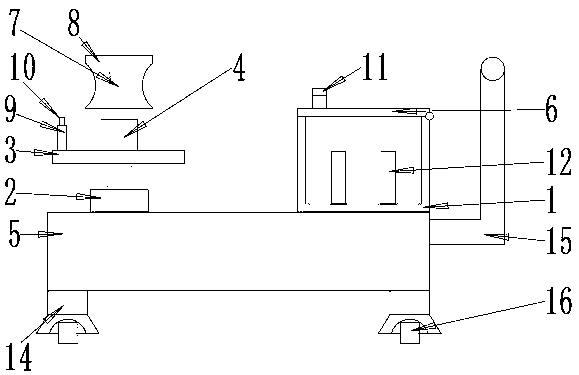

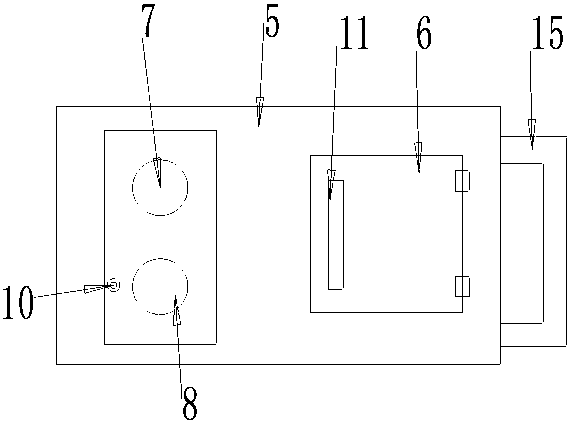

[0020] Embodiment: In the idle place of the device, place all the electrical components with matching drivers, and connect all the above-mentioned drivers, which refer to the power components, electrical components and the adapted power supply, through wires by those skilled in the art, For the specific connection method, please refer to the following working principle. The electrical connection between the electrical components is completed in sequence. The detailed connection method is a well-known technology in the field. The following mainly introduces the working principle and process, and does not discuss the electrical control. Explain that the specific work is as follows: first, the first handle 15 is used to push the workbench 5 to move. At this time, the universal wheel 14 will move under the force. The limit is fixed to avoid movement during work, and then a pair of first electric control push rods 2 will drive the bearing plate 3 to move up or down to find the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com