Entrainment Fluid Detection and Diagnosis

A fluid and process fluid technology, applied in the field of dragged fluid detection and diagnosis, which can solve problems such as damage to the system and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

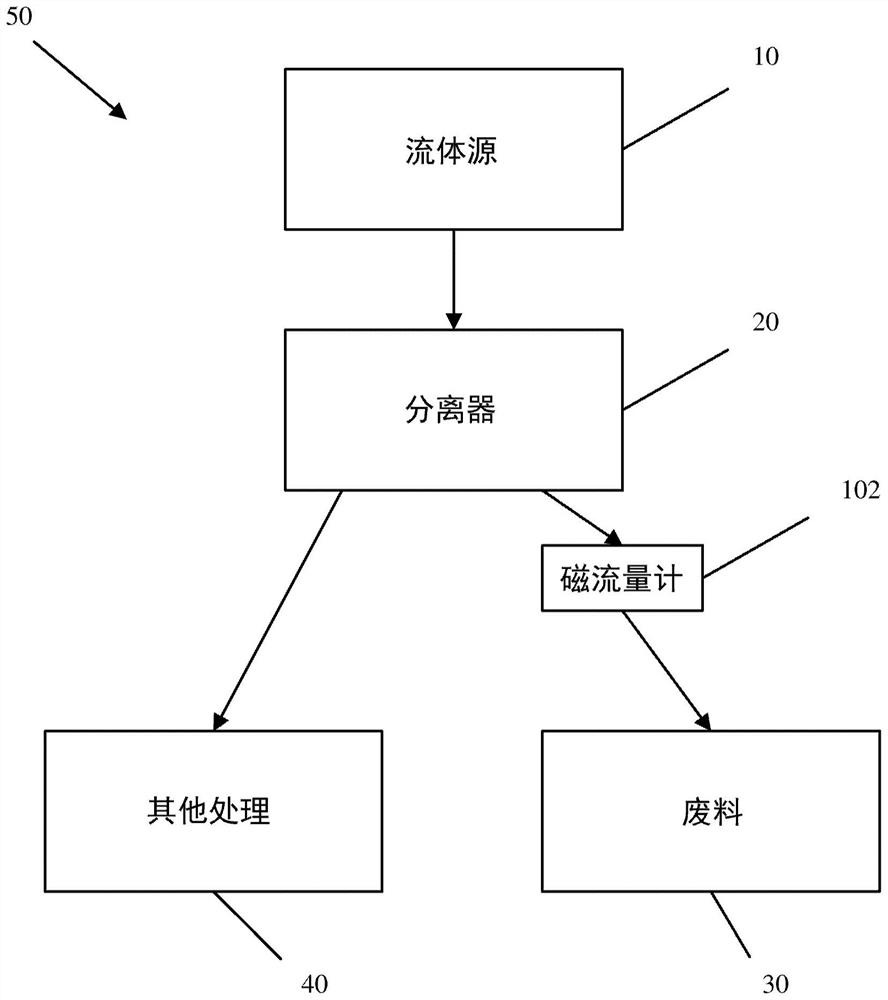

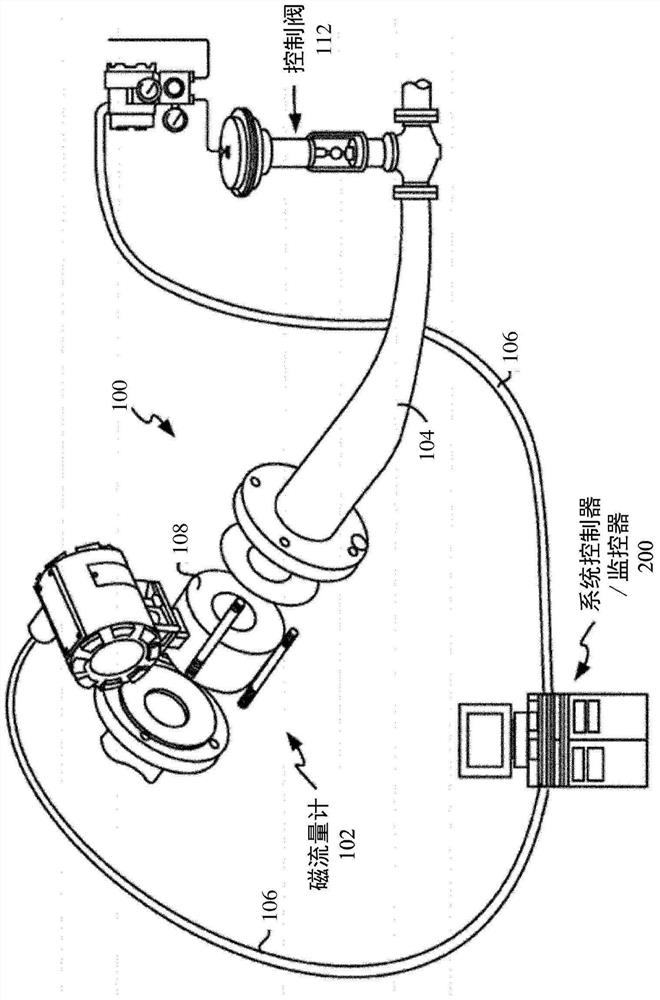

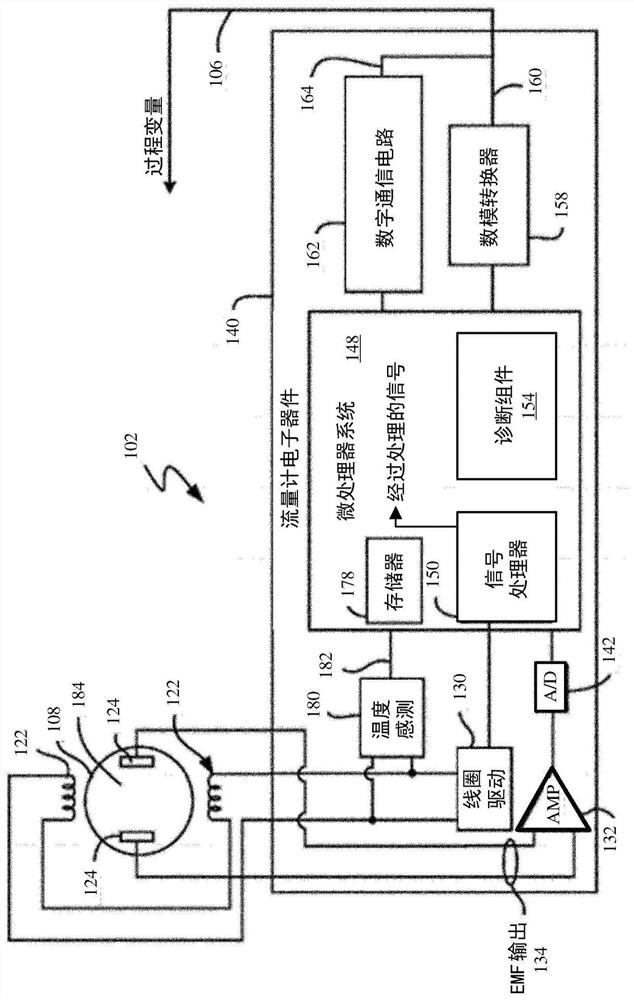

[0011] figure 1 A simplified example procedural environment for specific use by embodiments of the invention is shown. Process fluid may be circulated in, or produced by, the example process environment 50 . The process fluid can be natural gas, oil or other fluids. Fluid originates from an example fluid source 10, such as a wellhead, and is provided to a separator 20, wherein the separator 20 is configured to separate liquid from non-productive material, for example, from fracturing fluid (fracturing fluid). cracked) or treated water to separate natural gas. In one embodiment, as the liquid passes through separator 20, the product continues to flow in process stream 40 for other downstream processing. Instead, non-product matter may be directed to waste stream 30 . Flow meter 102 is configured to measure one or more process variables or parameters related to waste stream 30 exiting separator 20 .

[0012] Early detection of entrained fluid in process streams can minimize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com