An Optimum Structure for Adjusting the Movement of the Cutting Die

A technology of mobile adjustment and optimized structure, which is applied in the direction of metal processing, etc., can solve the problems of large upper and lower tolerances, inability to fit tightly, and large contact area of the moving knife part of the knife die, and achieve reduced contact area, tight fit, and quick disassembly and assembly of tools Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

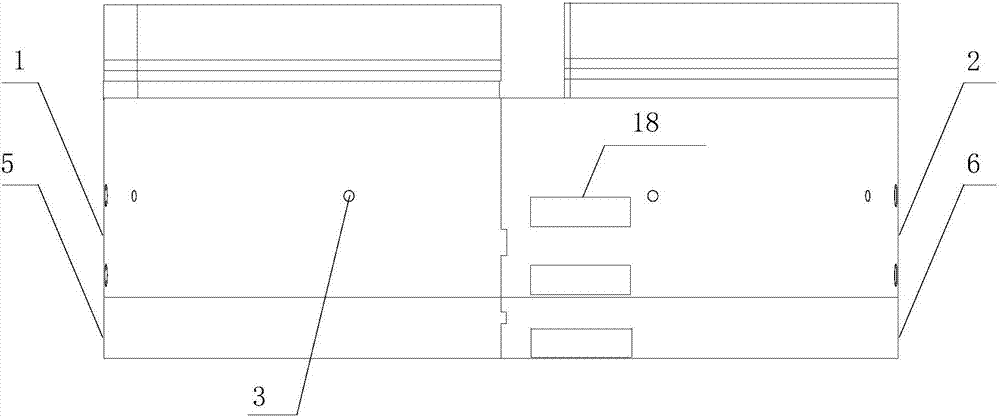

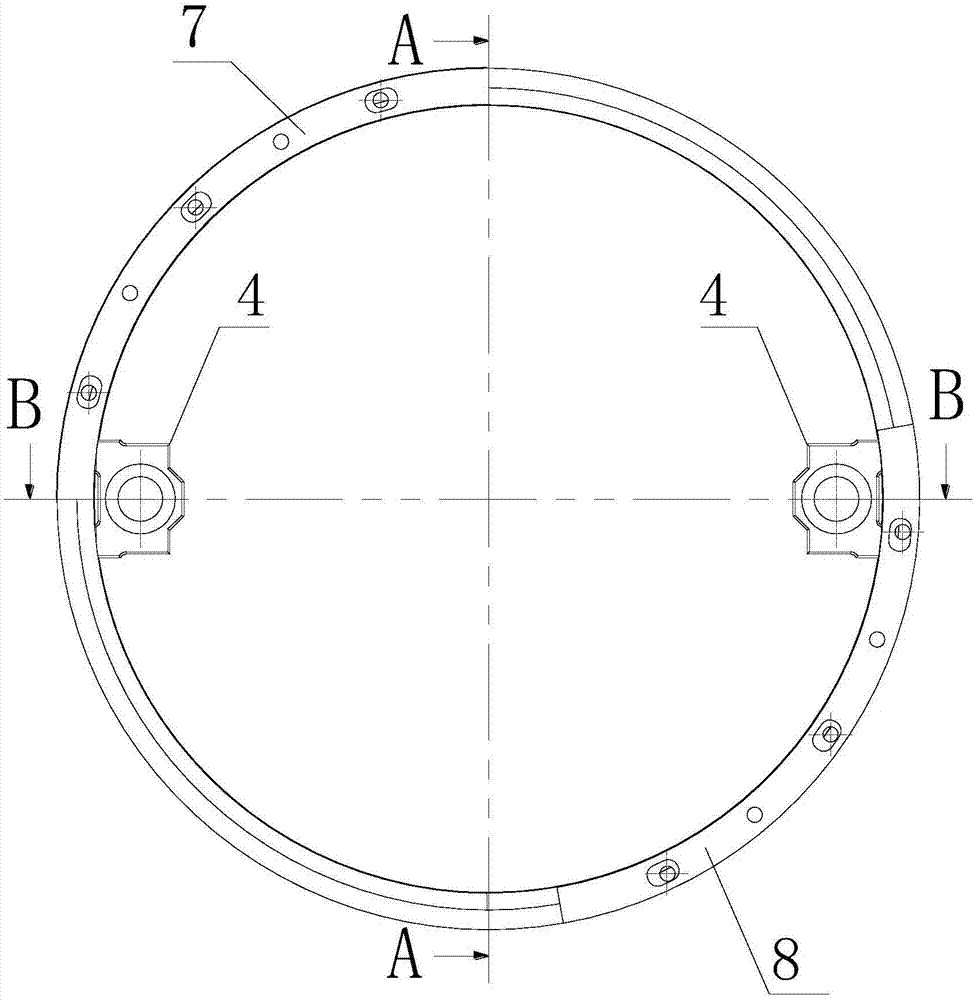

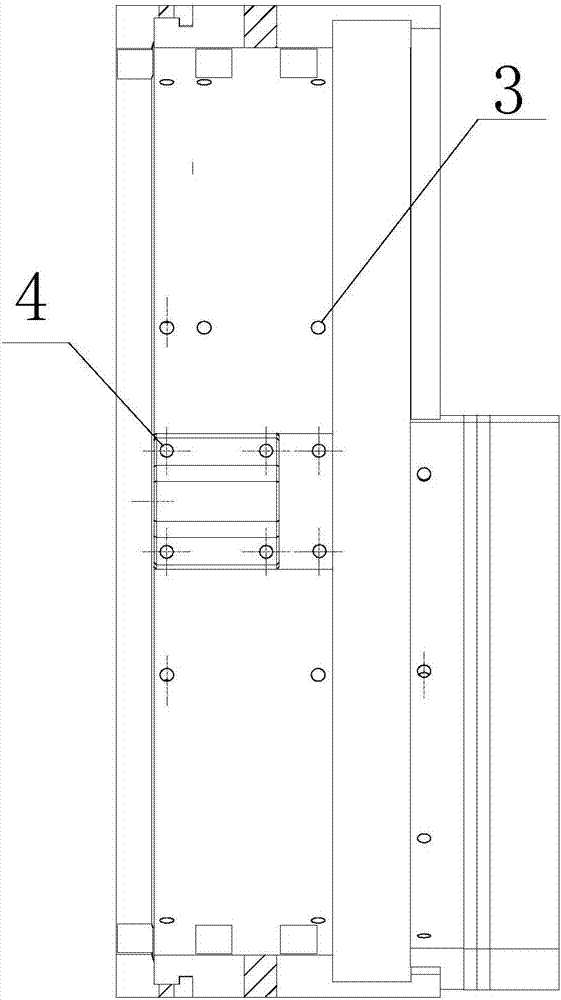

[0037] see Figure 1-14 , an optimized structure for adjusting the movement of the knife mold, including a knife mold main body, the knife mold main body is composed of a fixed knife main body, and the fixed knife main body is composed of a first fixed knife main body 1 and a second fixed knife main body 2 which are symmetrically arranged. The fixed knife main body 1 and the second fixed knife main body 2 are connected to each other to form a ring structure. The first fixed knife main body 1 and the second fixed knife main body 2 are provided with several steel ball embedding holes 3 that cooperate with steel balls. The first fixed knife main body 1 and the inner side of the second fixed knife body 2 are provided with a linear sliding unit slider 4, and the bottoms of the first fixed knife body 1 and the second fixed knife main body 2 are respectively installed with the first knife mold fixing ring 5 and the second knife mold fixed ring 5. Circle 6, the top of the first fixed ...

Embodiment 2

[0048] see Figure 15-21 , as another implementation of the present invention, the two ends of the grooved linear optical axis 22 are installed on the drum 41 through the linear optical axis fixing seat 42, and the middle part of the linear optical axis fixing seat 42 is provided with the grooved linear optical axis 22 The matching optical axis hole, the two sides of the optical axis hole are provided with fixing holes, the linear optical axis fixing seat 42 is fixed on the roller 41, the grooved linear optical axis 22 passes through the optical axis hole, and the grooved linear optical axis 22 is located on the linear optical axis The outer part of the shaft fixing seat 42 is sequentially covered with a thrust bearing 43, an adjusting hexagonal sleeve 44 and a round nut 45, wherein the inner circumference of the adjusting hexagonal sleeve 44 is provided with a protrusion matching the groove of the groove linear optical axis 22, the protrusion Snap into the groove of the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com