Wiring terminal

A terminal and terminal technology, applied in the direction of connection, contact parts, parts of connection devices, etc., can solve the problems of complex structure, affecting production efficiency, many assembly parts, etc., and achieve good connection reliability, fast self-locking or separation. , The effect of easy and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

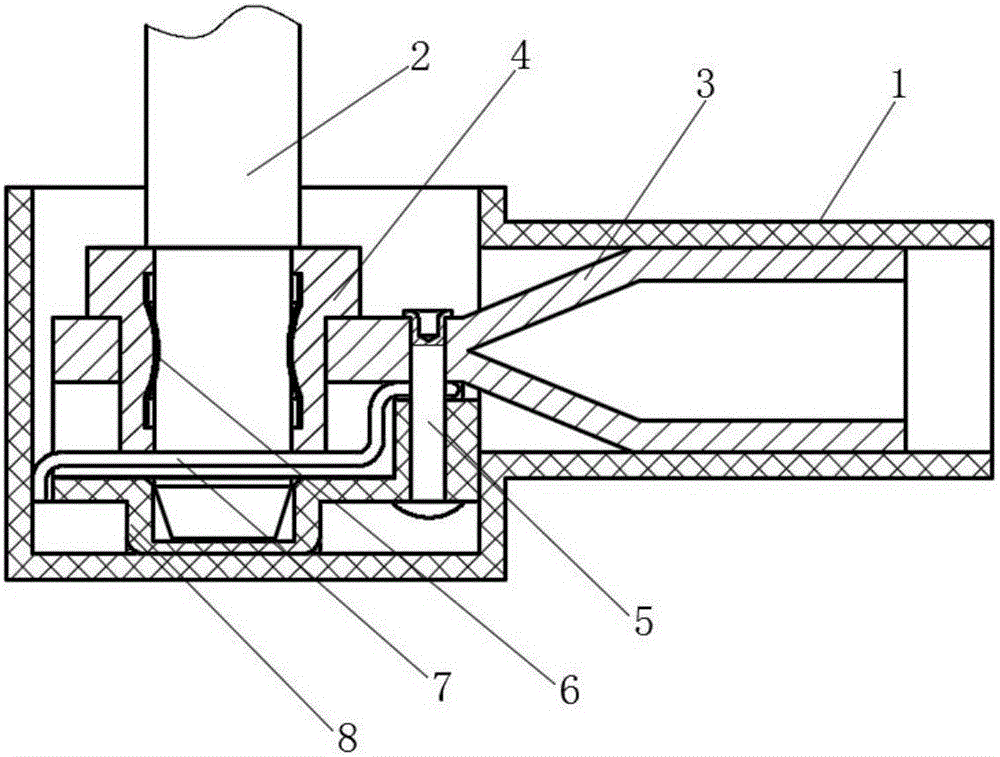

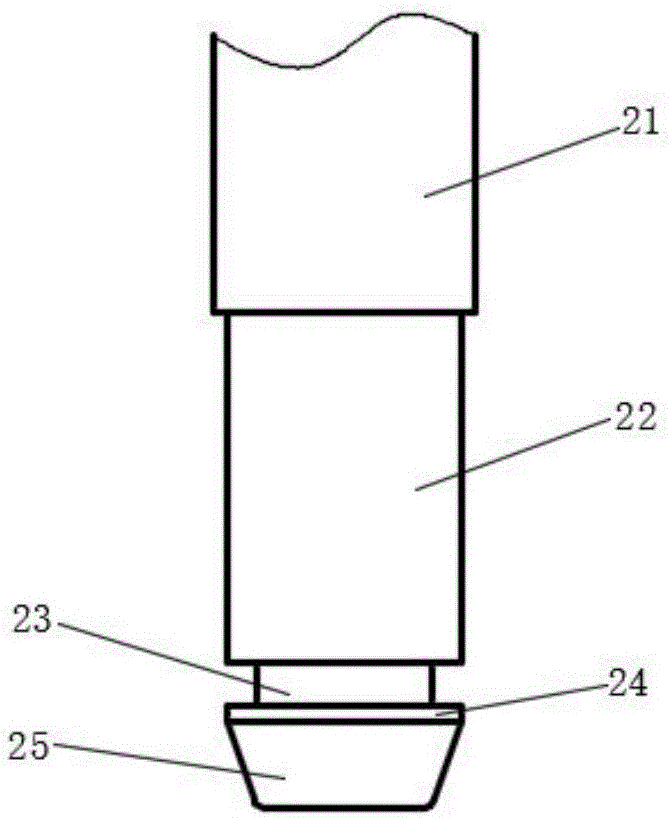

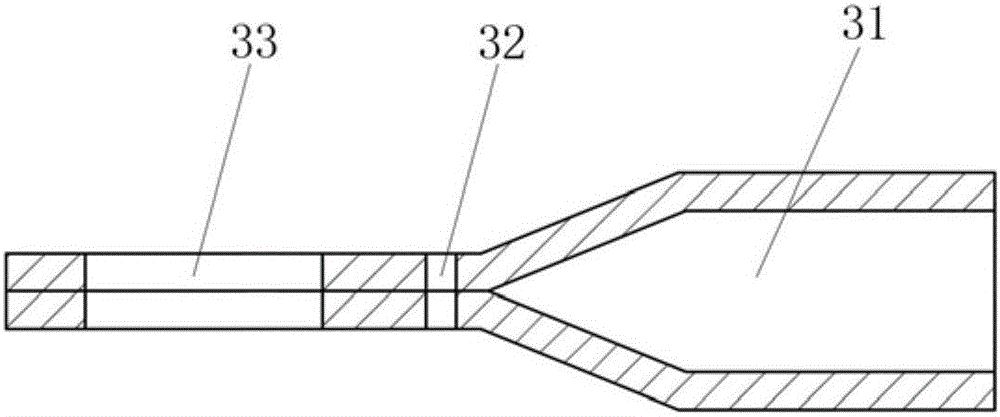

[0046] Such as Figure 1-25 As shown, the terminal of this embodiment includes a contact pin 2 , a terminal body 3 , a convex support 4 , a rivet 5 , a crown spring 6 , an elastic member 7 and a support member 8 . The contact pin 2 includes an external section 21, a contact section 22, a locking section 23, a buffer section 24, and an insertion section 25 from top to bottom. The external section 21, the contact section 22, the locking section 23, and the buffer section 24 are all It is a cylindrical structure with the same axis, the diameter of the external section 21 is greater than the diameter of the contact section 22, the diameter of the contact section 22 is greater than the diameter of the locking section 23, and the diameter of the contact section 22 is equal to the diameter of the buffer section 24; the insertion section 25 is a cylindrical structure with a trapezoidal cross section, the diameter of the upper bottom surface is equal to the diameter of the buffer secti...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that: any possible angle is formed between the terminal body terminal and the contact hole, and the angle is 0-360°, which can be selected according to actual needs and can be adapted to different applications. For other structures, please refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com