Electric hydraulic device

A hydraulic device and electric technology, applied in the field of disaster relief equipment, can solve problems such as low operating efficiency, affecting rescue time, inconvenient use, etc., and achieve the effect of high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

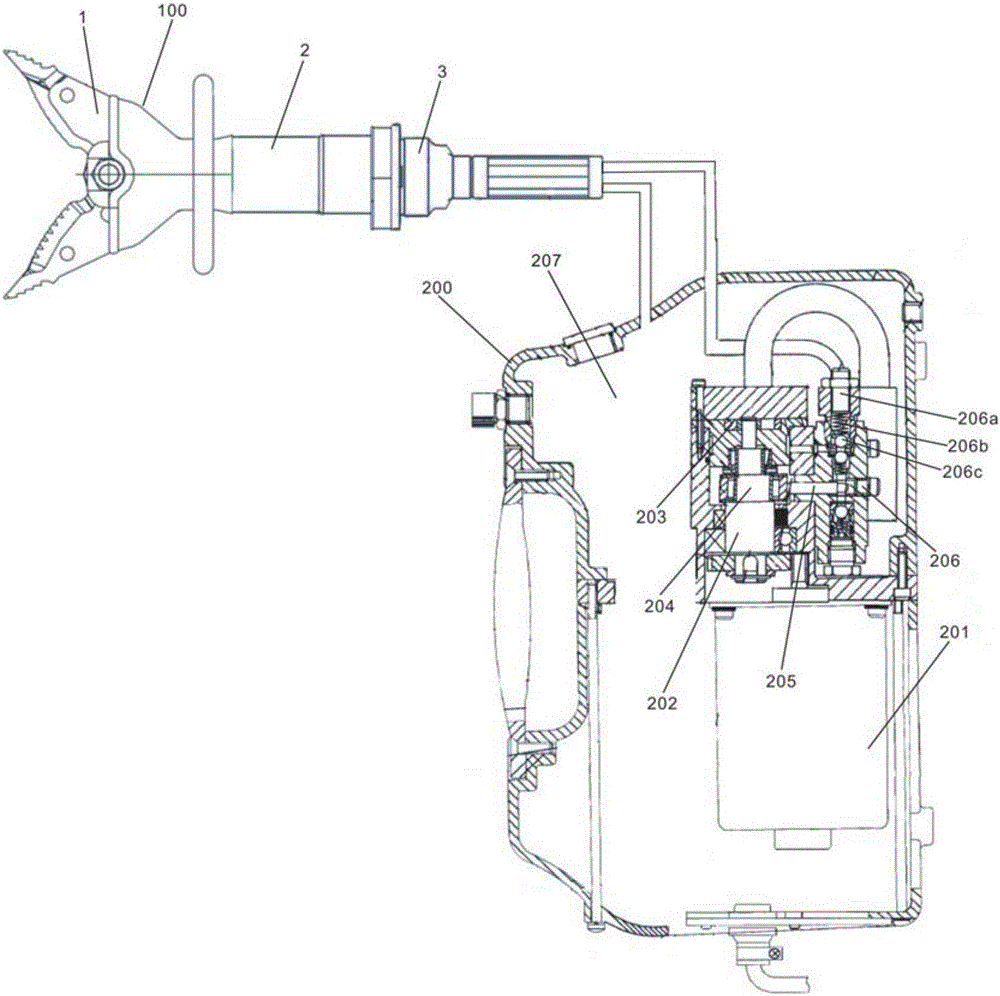

[0042] Such as figure 1 As shown, the electrohydraulic device provided in this embodiment includes a working head 100 and a power pump 200 . The working head 100 includes a work piece 1 , a hydraulic drive assembly 2 and a reversing assembly 3 , and the hydraulic drive assembly 2 is connected to the work piece 1 to drive the work piece 1 to work. The reversing assembly 3 provides the hydraulic drive assembly 2 with oil circulation in two opposite directions. The power pump 200 is connected with the reversing assembly 3 and delivers hydraulic oil to the reversing assembly 3 .

[0043] In this embodiment, the work piece 1 is a shear. However, the present invention does not make any limitation thereto. In other embodiments, the workshop 1 can be other work pieces such as a shear expander, expander, or propper.

[0044]In this embodiment, the power pump 200 includes a driving motor 201 , a rotating shaft 202 , an impeller assembly 203 , an eccentric shaft 204 , a piston 205 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap