A collection device for terminal production and processing

The technology of a terminal and a collecting device is applied in the field of collecting devices for the production and processing of the terminal, which can solve the problems of low production efficiency, and achieve the effects of improving the production efficiency, increasing the fault tolerance rate, and improving the stability of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

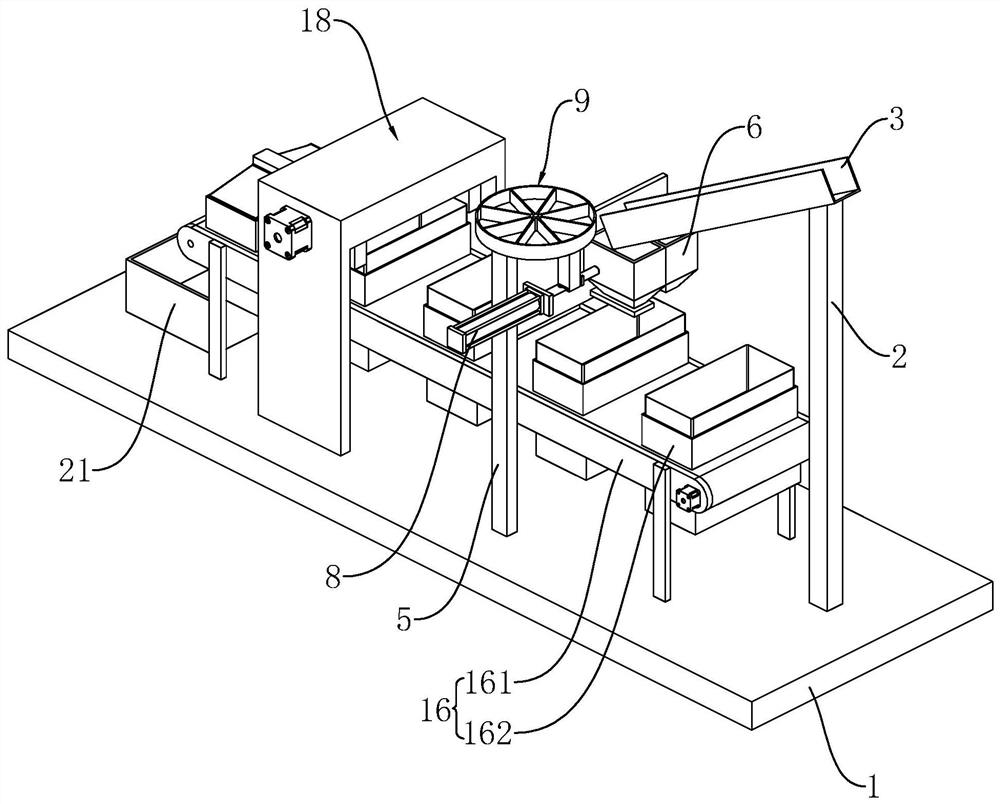

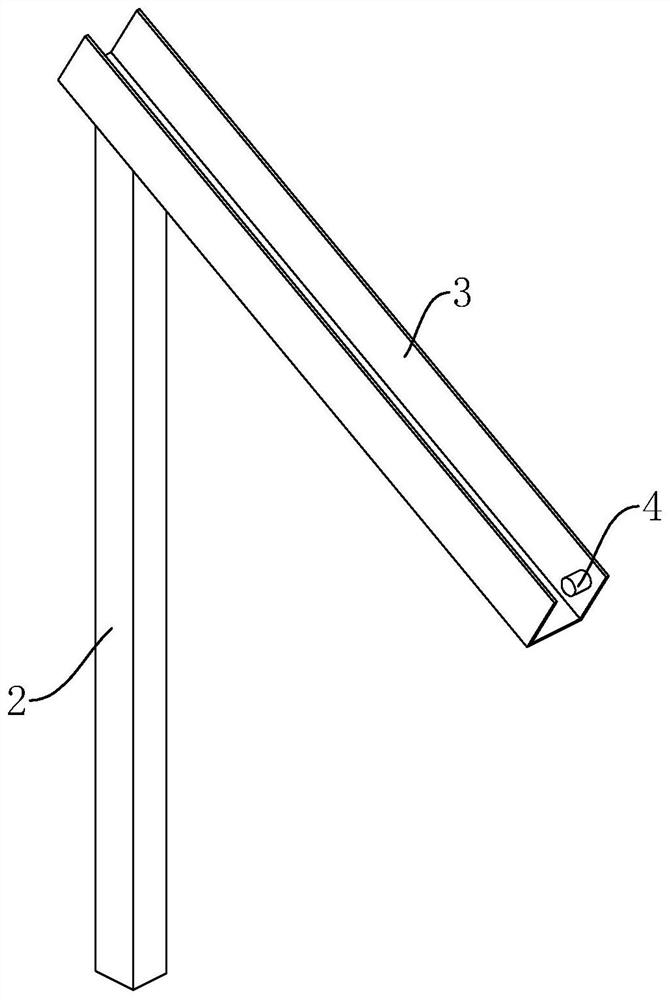

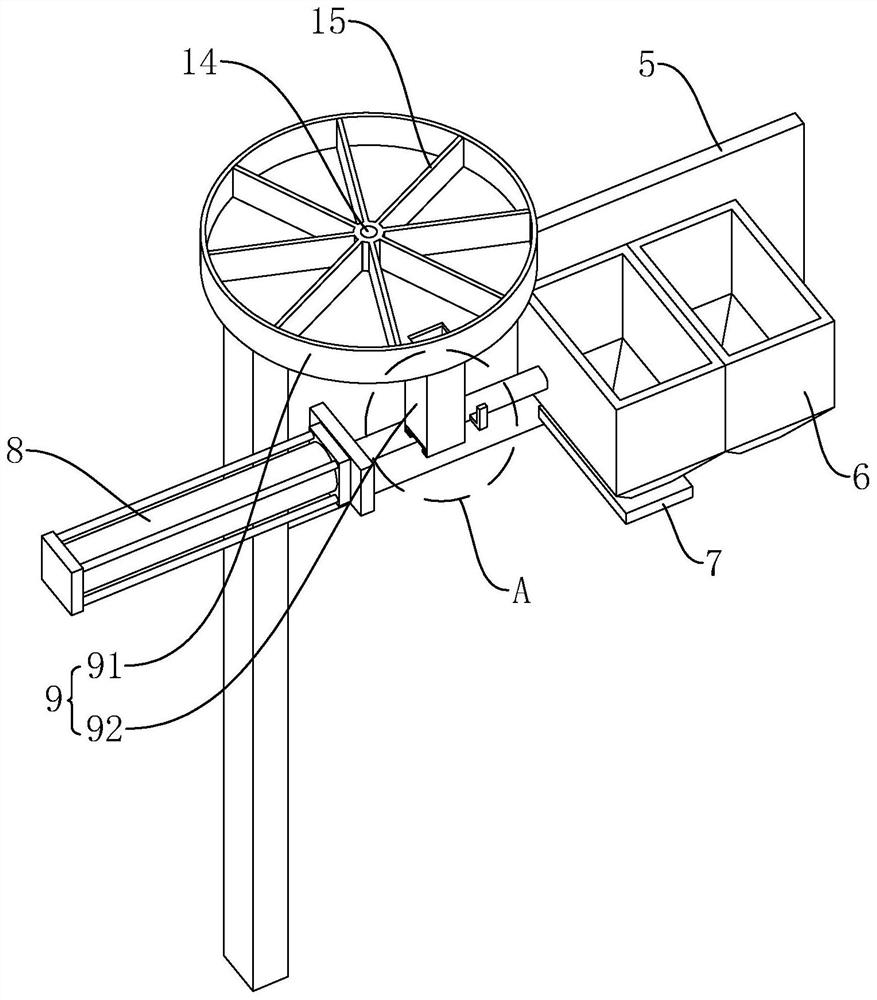

[0044] refer to figure 1 and figure 2 The collecting device for terminal production and processing includes a horizontally arranged workbench 1 , the upper end surface of the workbench 1 is vertically fixedly connected with a support rod 2 , and the upper end surface of the support rod 2 is fixedly connected with a guide rail 3 . The guide rail 3 is arranged in an inclined shape with the feed port higher than the discharge port, and the feed port of the guide rail 3 is used to align with the discharge port of the terminal production equipment. In this way, the finished terminal blocks can slide through the guide rail 3 in turn, thereby realizing separate transportation of the finished terminal blocks.

[0045] refer to figure 1 and figure 2 , the guide rail 3 is fixedly connected with an infrared counter 4, and the signal transmitter and signal receiver of the infrared counter 4 are respectively fixedly connected on the inner walls of both sides of the discharge port of t...

Embodiment 2

[0073] refer to Figure 7 The difference between this embodiment and Embodiment 1 is that the feeding mechanism includes a pair of feed rollers 22 horizontally rotatably connected to the side wall of the mounting frame 5, and there is a gap between the pair of feed rollers 22 for the entire string of dry bags to enter. . The side wall of the mounting frame 5 is fixedly connected with two drive motors 23, and the output shafts of the two drive motors 23 are respectively fixedly connected with one end of the corresponding feeding roller 22, thereby providing a stable driving force for the rotation of the feeding roller 22. The output shafts of the two driving motors 23 rotate in different directions synchronously, so that when the two feeding rollers 22 rotate in different directions synchronously, the whole string of dry bags can be transported.

[0074] refer to figure 1 and Figure 7 , the feeding mechanism also includes a feed pipe 24 vertically fixedly connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com