Steel bar mechanical connecting structure and installation method

A mechanical connection structure and mechanical connection technology, applied to structural elements, building components, building structures, etc., can solve the problems of difficult construction of steel bar connection and low reliability of connection quality, so as to reduce residual deformation and ensure connection quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

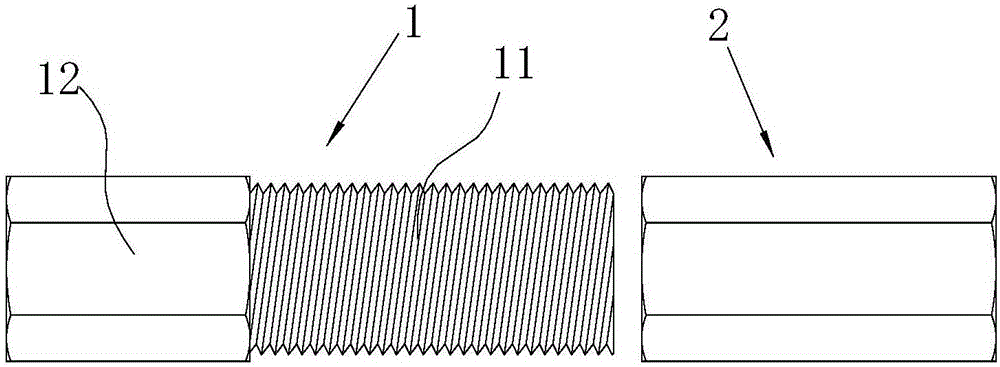

[0031] Step a. According to the diameter and type of the connecting steel bar, use the supporting stud 1 with connecting cap and the mechanical connecting sleeve 2. Connecting cap 12 of column 1, such as figure 2 shown;

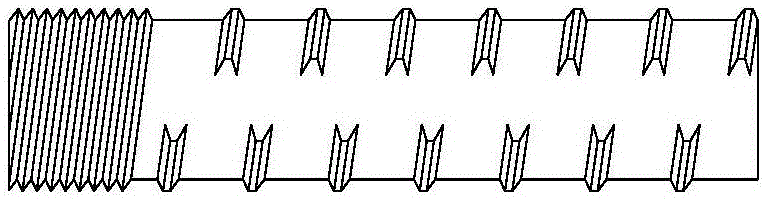

[0032] Step b. Before the prefabricated component or the steel bar skeleton is bound to the steel bars, process the ends of the first connecting steel bar 3 and the second connecting steel bar 4 to be connected and make threaded threads. The depth and length of the threaded heads must meet the corresponding requirements of mechanical connection. Such as image 3 shown;

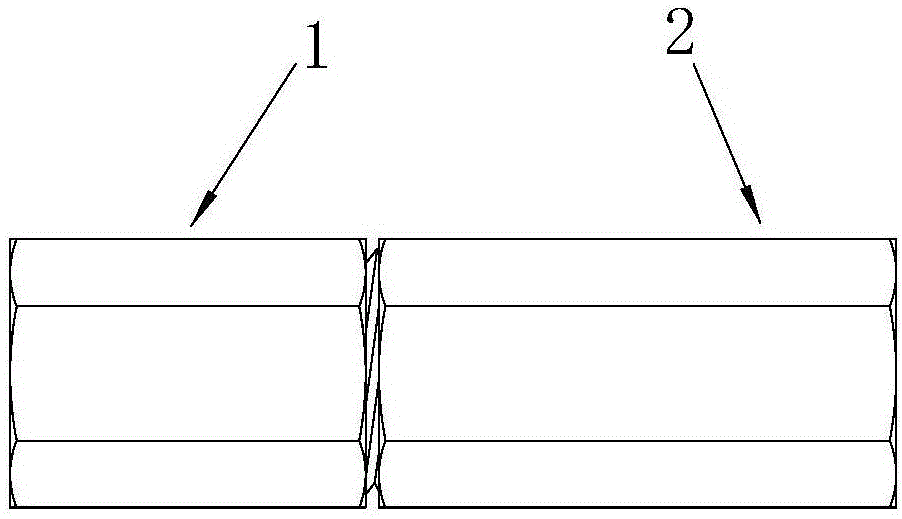

[0033] Step c, on-site positioning and fixing of prefabricated components or reinforced skeletons, such as Figure 4 As shown, to ensure that the connectors can be screwed in accurately and the gap at the joint must meet the requirements. When the position or alignment of the connected steel bars cannot meet the requirements, the connecting steel bars need to be processed or the connectin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap