Method for fracturing high-angle naturally-fractured oil reservoir by using permanent plugging agent

A natural fracture, high-angle technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low production, insufficient reservoir stimulation, etc., to ensure full stimulation, increase single well production, and successfully rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

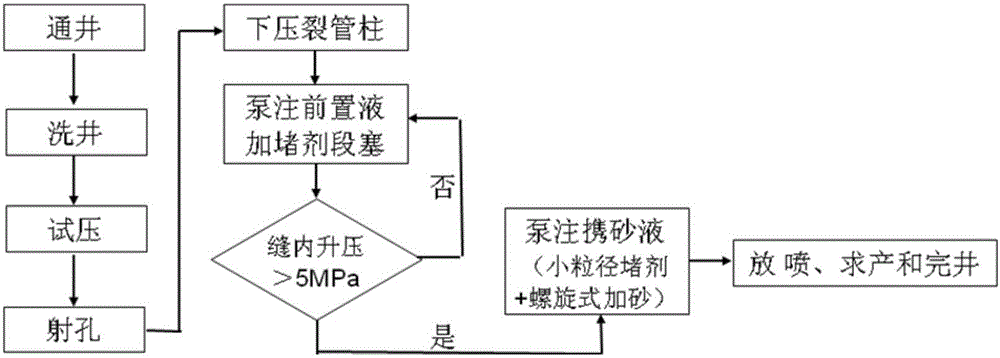

Method used

Image

Examples

Embodiment

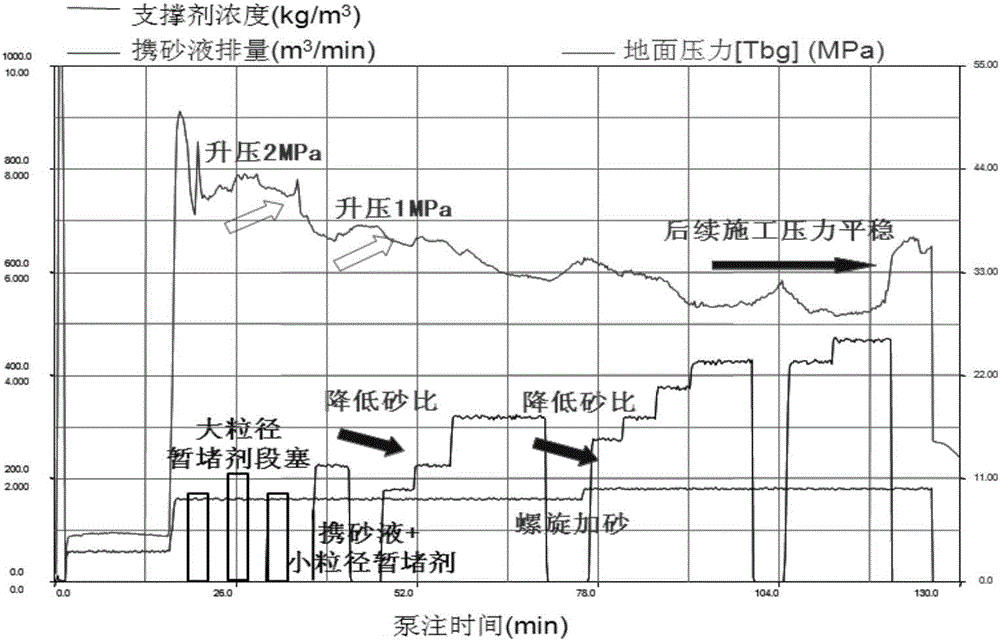

[0052] see figure 2As shown, taking the test well A as an example, a large particle size temporary plugging agent is added in the pre-fluid stage, pumped for 3 pulses, and the construction pressure rises by 2 MPa to initially plug high-angle fractures; a small particle size temporary plugging agent is added in the initial stage of the sand-carrying fluid stage proppant, and the pressure increased by 1 MPa, the purpose is to reduce the construction pressure by grinding the fractures near the wellbore, plugging micro-fractures, and improving the liquid efficiency, so as to ensure the effective filling of the subsequent main fracturing with conventional proppants. In the later stage of the main fracturing sanding, the spiral sanding method is used to add sand. The so-called spiral type means that the sand is added step by step from a low sand ratio, and after a few steps, the sand ratio is reduced and the sand ratio is lowered again. This method of adding sand can effectively re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com