Inkjet head and inkjet printer

An inkjet head and nozzle technology, applied in printing, inking device, etc., can solve problems such as adverse effects of spitting in the spitting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

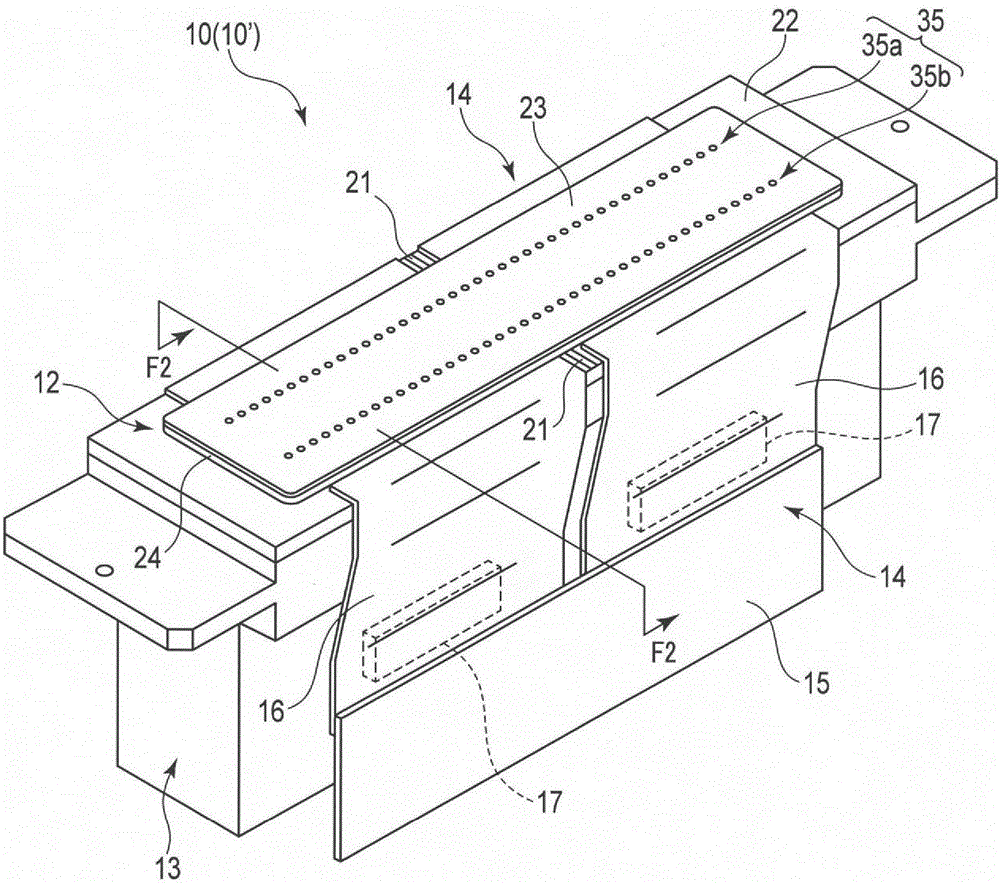

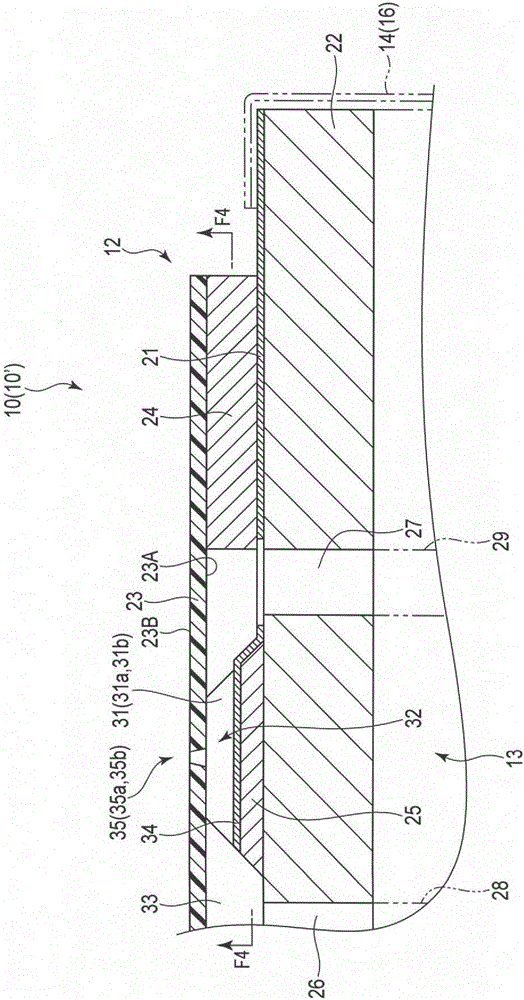

[0019] Embodiments will be described below with reference to the drawings.

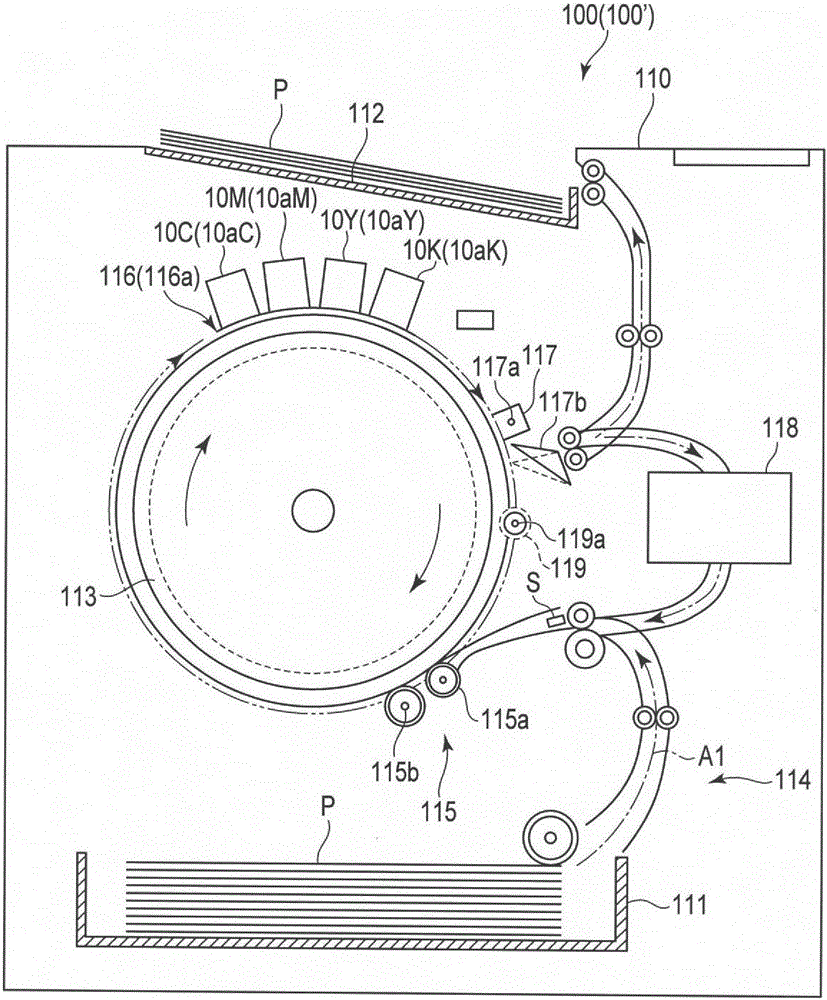

[0020] figure 1 It is a diagram showing a configuration example of the inkjet printer 100 according to the embodiment.

[0021] The inkjet printer 100 is a device that performs various processes such as image formation while conveying paper P as a printing medium along a predetermined conveyance path. The inkjet printer 100 includes an inkjet head 10 , a casing 110 , a paper feed cassette 111 as a paper supply unit, a paper discharge tray 112 as a discharge unit, holding rollers 113 , a transport device 114 , and an inverting device 118 .

[0022] The housing 110 constitutes the exterior of the inkjet printer 100 . Paper feeding cassette 111 is provided inside housing 110 . Paper feed cassette 111 stores paper P. A paper discharge tray 112 is provided on an upper portion of the casing 110 . The paper discharge tray 112 is used to discharge the paper P on which an image is formed.

[0023] The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com