A method for removing oxygen from oxygen-containing light hydrocarbons

A light hydrocarbon and oxygen technology, applied in the fields of organic chemistry, absorption purification/separation, etc., can solve the problems of loss of deoxygenation capacity of light hydrocarbon gas, expensive catalyst cost, etc., and achieve the effect of reducing investment and consumption, simple process, and improving deoxygenation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example is used to illustrate the method for deoxygenating oxygen-containing light hydrocarbons of the present invention.

[0044] This embodiment deals with the oxygen-containing light hydrocarbon gas produced by the hydrogen peroxide process propylene oxide industrial device, and the composition of the oxygen-containing light hydrocarbon gas and the C4 absorbent is shown in Table 1.

[0045] Table 1

[0046] Mass composition (weight%)

Oxygenated light hydrocarbon gas

C4 absorbent

Nitrogen

0.24

-

oxygen

4.34

-

carbon dioxide

0.48

-

ethane

14.58

-

Vinyl

56.78

-

propane

5.37

-

Propylene

18.15

-

n-butane

0.06

27.91

Isobutane

-

15.59

1-butene

-

7.72

Isobutylene

-

0.04

trans-2-butene

-

28.44

cis-2-butene

-

20.23

water

-

0.01

Dimethyl ether

-

0.06

[0047] ...

Embodiment 2

[0051] This example is used to illustrate the method for deoxygenating oxygen-containing light hydrocarbons of the present invention.

[0052] This embodiment deals with the oxygen-containing light hydrocarbon gas produced by the hydrogen peroxide process propylene oxide industrial device, and the composition of the oxygen-containing light hydrocarbon gas and the carbon five absorbent is shown in Table 3.

[0053] table 3

[0054] Mass composition (weight%)

Oxygenated light hydrocarbon gas

C5 absorbent

Nitrogen

0.36

-

oxygen

4.39

-

carbon dioxide

0.23

-

Methanol

1.04

-

propane

4.78

0.02

Propylene

89.13

0.26

n-butane

0.07

0.01

Isopentane

-

0.63

n-pentane

-

34.03

Cyclopentane

-

17.05

2,3-Dimethylbutane

-

8.83

2-Methylpentane

-

27.42

n-Hexane

-

11.76

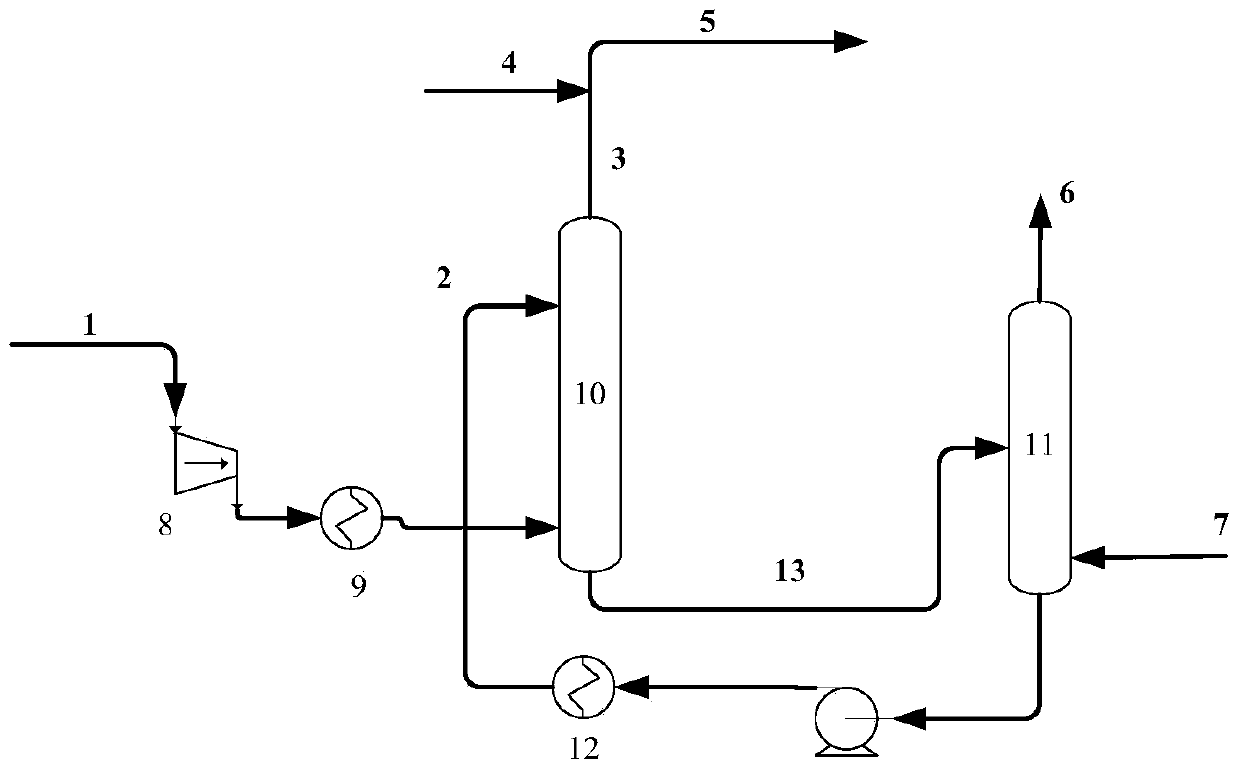

[0055] use as figure 1 The process show...

Embodiment 3

[0060] This example is used to illustrate the method for deoxygenating oxygen-containing light hydrocarbons of the present invention.

[0061] This embodiment deals with the oxygen-containing light hydrocarbon gas produced by the hydrogen peroxide process propylene oxide industrial device, and the composition of the oxygen-containing light hydrocarbon gas and the C4 absorbent is shown in Table 5.

[0062] table 5

[0063] Mass composition (weight%)

Oxygenated light hydrocarbon gas

C4 absorbent

Nitrogen

0.24

-

oxygen

3.21

-

carbon dioxide

0.31

-

Methanol

1.33

-

propane

1.91

-

Propylene

92.94

-

n-butane

0.06

27.91

Isobutane

-

15.59

1-butene

-

7.72

Isobutylene

-

0.04

trans-2-butene

-

28.44

cis-2-butene

-

20.23

water

-

0.01

Dimethyl ether

-

0.06

[0064] use as figure 1 The proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com