Novel production scheduling algorithm for solving job shop scheduling problem

A job shop, scheduling problem technology, applied in computing, manufacturing computing systems, instruments, etc., can solve problems such as the problem of not considering the combination of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

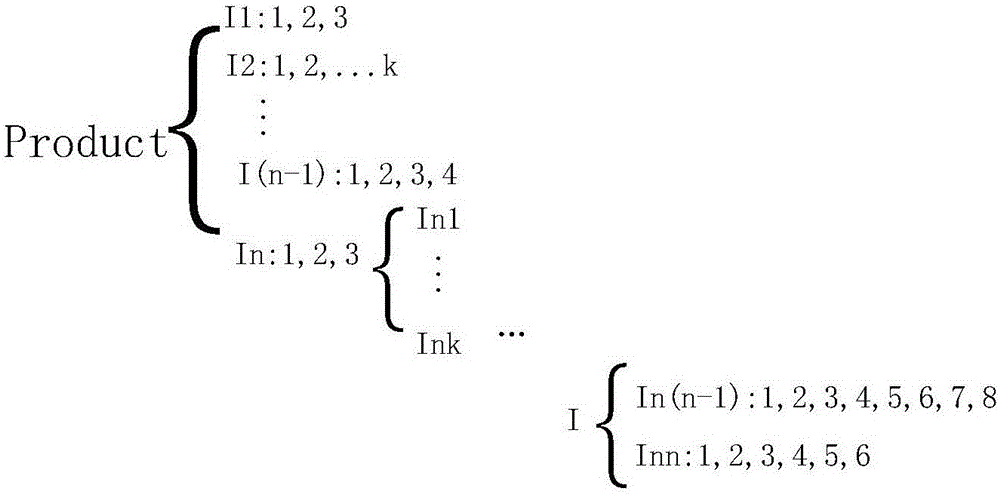

[0021] The algorithm proposed by the present invention solves the complex workpiece combination problems existing in the actual production process such as image 3 As shown, that is, multiple parts are combined to form a new part. This new part 1 may be combined with other workpieces to form a new part 2. The new part 2 may need to be processed and then assembled with a new part 3. An artifact, so cyclical problem.

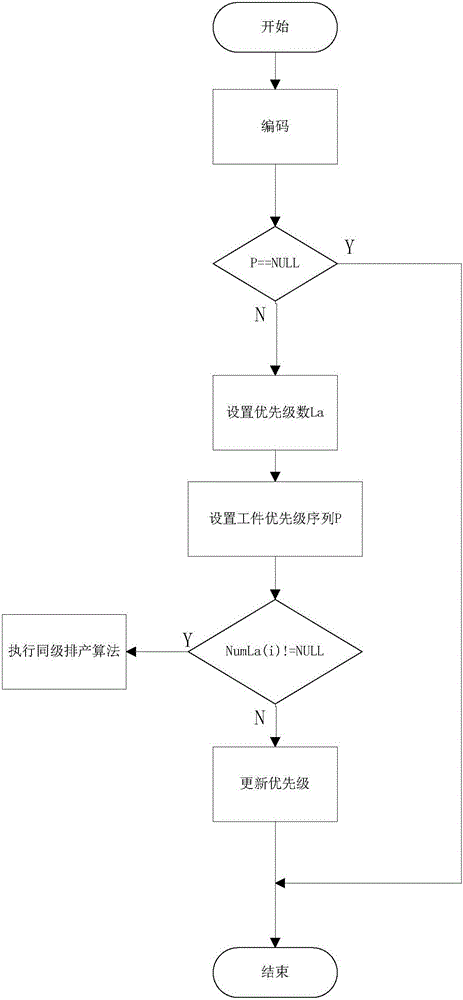

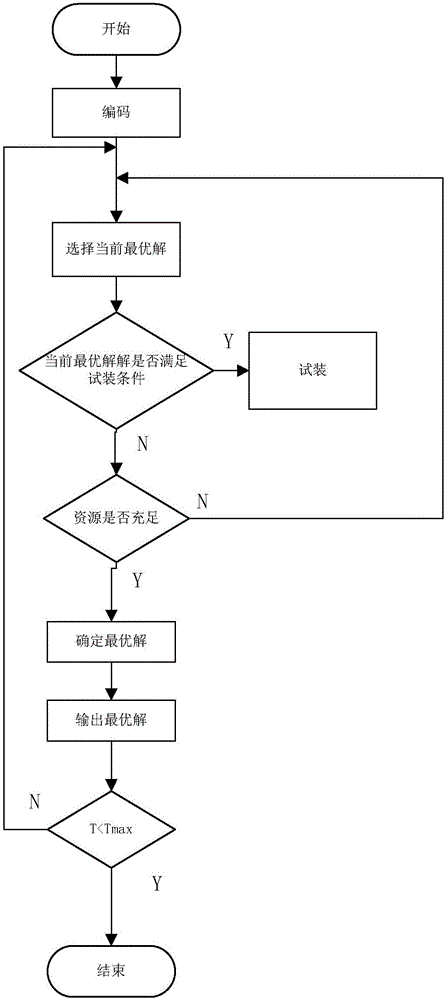

[0022] The present invention solves the above problems by adopting a new production scheduling algorithm for solving job shop scheduling problems, combining Figure 1 to Figure 3 , the specific implementation process of the algorithm is as follows:

[0023] Step 1: Coding, using process-based coding rules, that is, chromosomes are composed of w×n×m genes, which represent a sequence of processes. In this sequence of processes, each job number appears m times at most, and the chromosomes are composed of A two-dimensional space point (x, y) represents, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com