Production scheduling algorithm for solving job shop production problem

A job shop, algorithm technology, applied in computing, computing model, artificial life and other directions, to achieve good real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

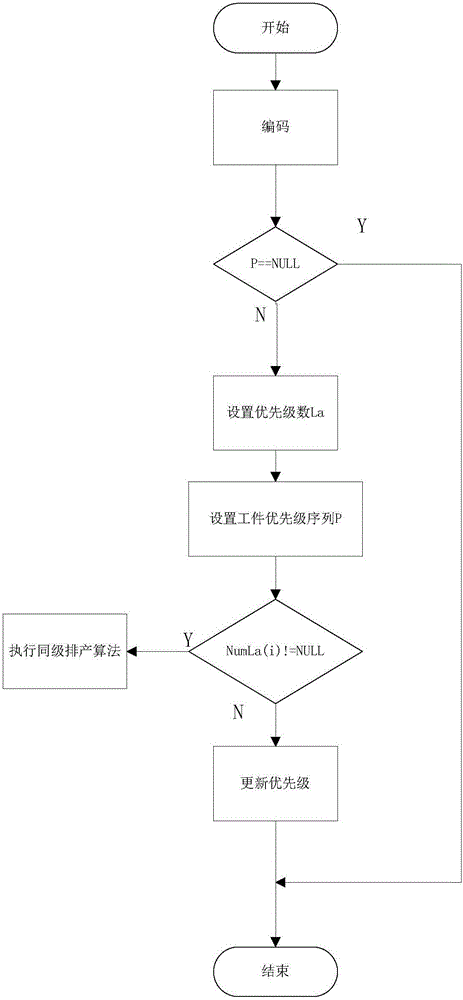

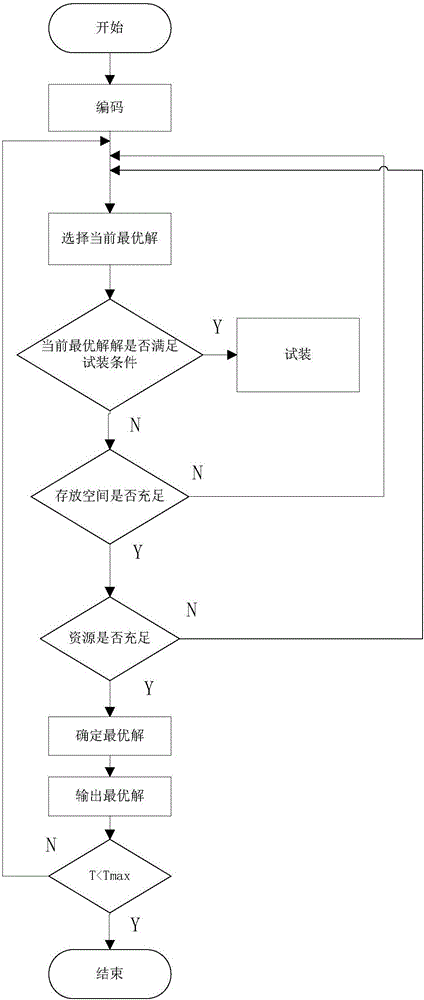

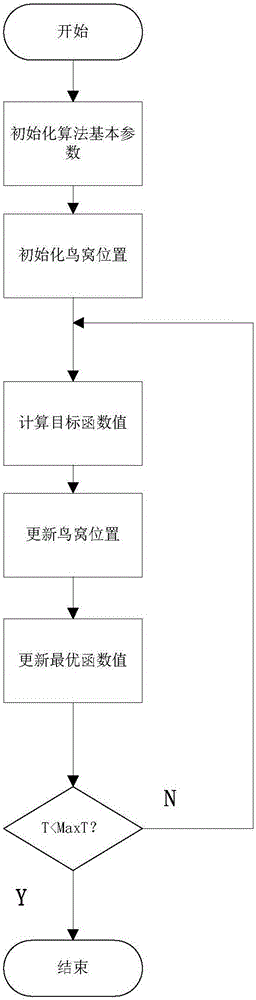

[0028] The following is attached Figure 1 to 5 , A detailed description of the present invention.

[0029] 1. Combination of trial assembly process in the actual production process Figure 4 The embodiment is described as follows: A number of small labor costs are trial-assembled into a relatively large labor price, and this large workpiece is processed in its process. When it is processed to a certain level (all its processes have not been completed), it needs to be disassembled , Its small parts and workpieces continue to go back to the process that has not been processed at the labor price, and after certain conditions are met, the labor costs are assembled again, and then the subsequent processes required for processing the workpiece are continued. The operation is repeated in sequence until the termination condition is met. The embodiment combines Figure 4 As follows: Workpiece 3 is assembled by work piece 1 and labor cost 2. Workpiece 1 has 5 procedures to be processed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com