Improved production scheduling algorithm for solving workshop production problem

An algorithm and problem-solving technology, applied in the field of workshop scheduling, can solve the problems of disrupting the processing sequence, not considering the problem of workpiece inventory, not considering the constraint conditions of the order cycle, etc., to ensure that it will not be disrupted and the accuracy of the algorithm is high Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

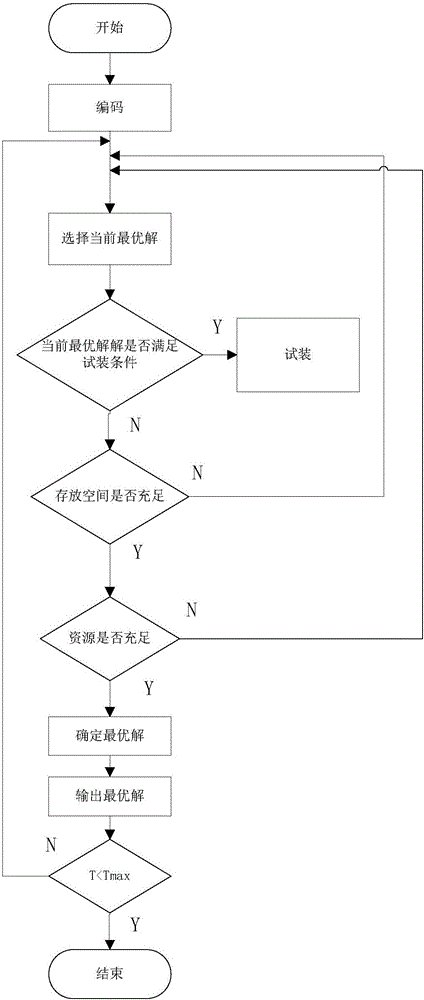

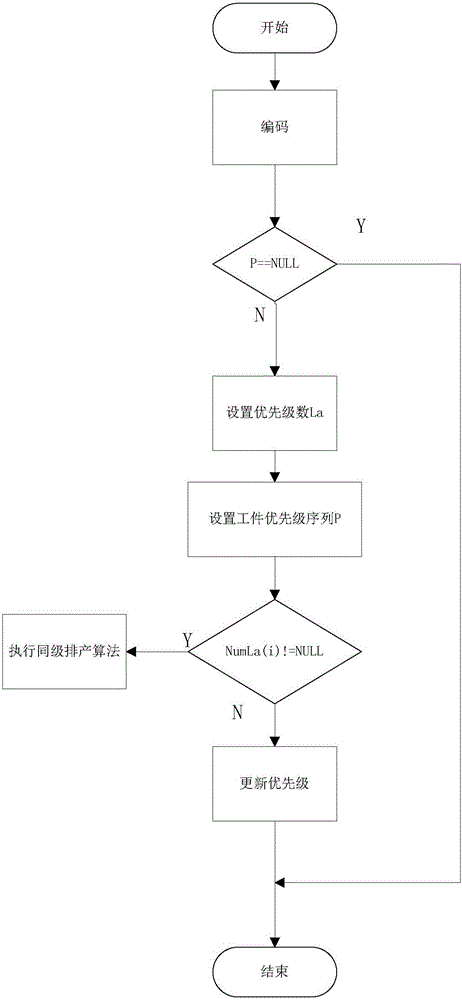

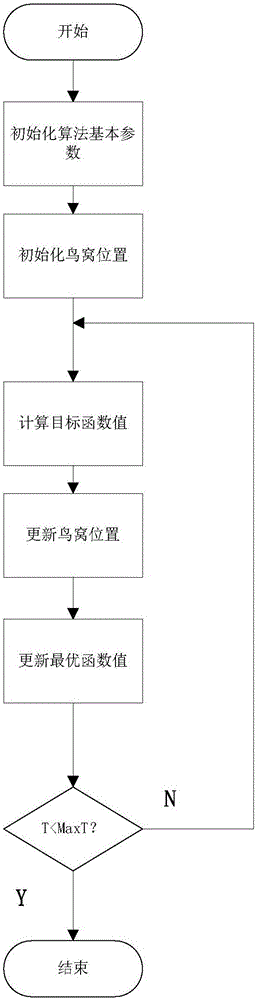

[0029] The following is attached Figures 1 to 5 , describe the present invention in detail.

[0030] 1. Combination of the trial assembly process in the actual production process Figure 4 Embodiment, description is as follows: several small wages are trial-assembled into a relatively large wage, and this large workpiece just carries out its procedure processing, when processing to a certain extent (not finishing all its procedures), it needs to be disassembled , Its small parts and workpieces continue to go back to process the processes that have not yet been processed by the workers. After reaching certain conditions, the workers are assembled again, and then continue to process the subsequent processes required by the workpiece. Repeat the operation sequentially until the termination condition is met. Its embodiment combines Figure 4 As follows: workpiece 3 is assembled from workpiece 1 and wager 2, workpiece 1 has 5 processes to be processed, and wager 2 has 9 process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com