Device for marinating chicken feet with mentha

A technology of making chicken feet and material boards made of lotus brine, which is applied in the direction of food science, etc., can solve the problems of incomplete cooling of chicken feet, long draining time, poor draining effect, etc., and achieve good draining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Hammer: A heavy object that travels downwards by the force of gravity.

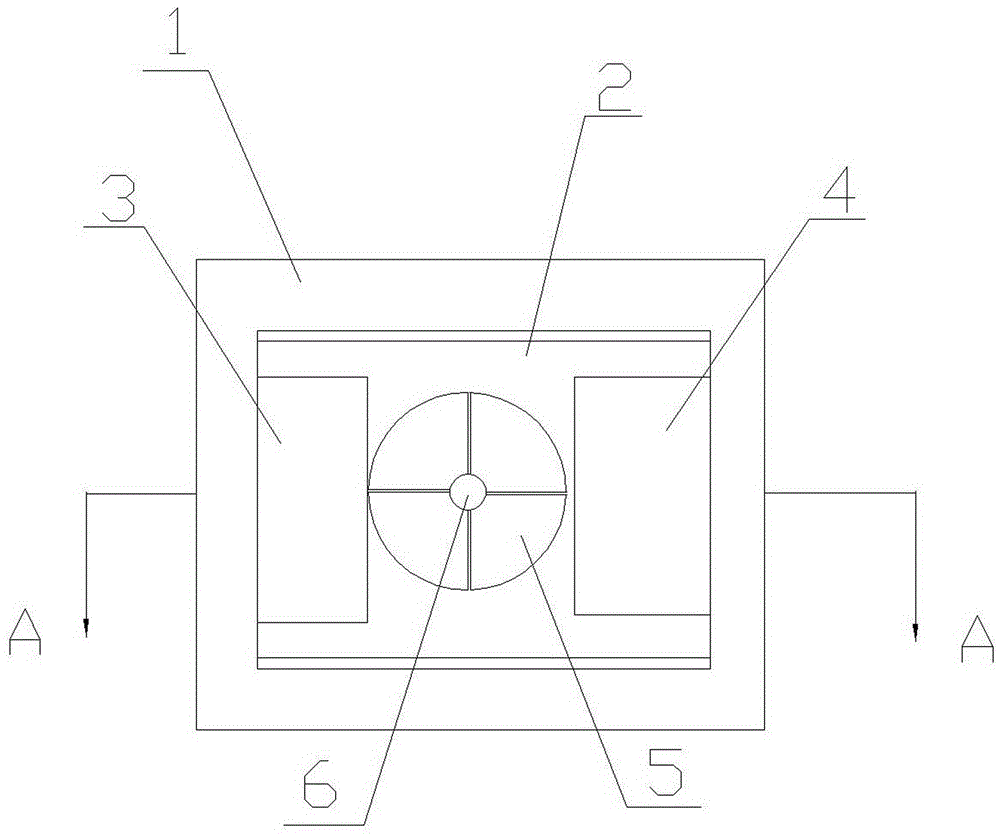

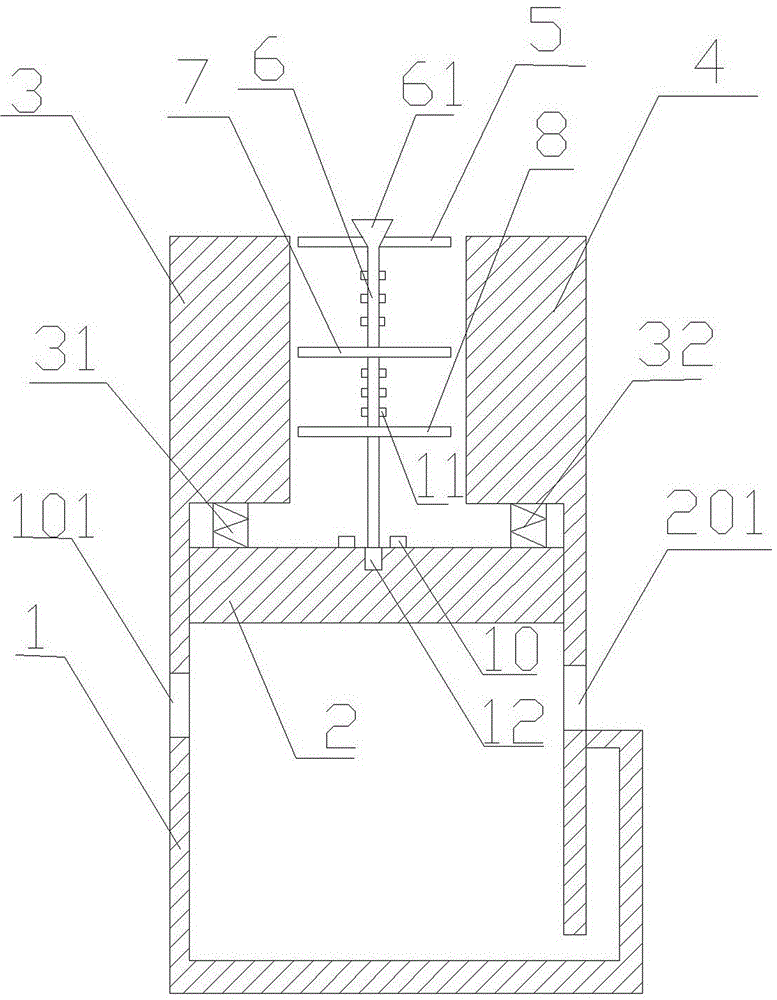

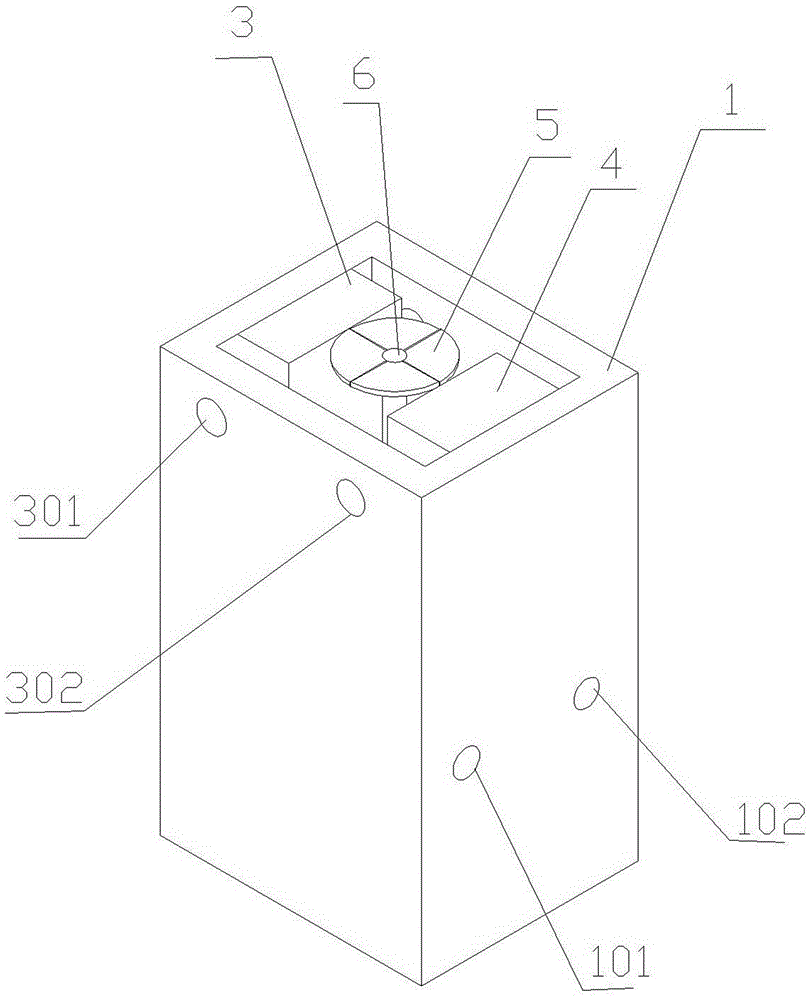

[0022] like figure 1 As shown, the cabinet 1 is included, and the cabinet 1 is divided into two layers, and the two layers are detachable. The feed port is set as a bar-shaped feed port, the first weight 3 and the second weight 4 are arranged on both sides above the material plate 2, and the first pressure spring 31 is arranged at the lower end of the first weight 3 , the other end of the first compression spring 31 is fixed on the material plate 2, the lower end of the second weight 4 is provided with a second compression spring 32, the other end of the second compression spring 32 is fixed on the material plate 2, the first weight 3 A rotating shaft 6 is arranged between the second heavy hammer 4, such as figure 2 As shown, three equidistant crushing disks are installed on the rotating shaft 6, which are respectively the first crushing disk 5, the second crushing disk 7 and the third crushing ...

Embodiment 2

[0025] The difference from Example 1 is that, as figure 2 As shown, a liquid level detection device is provided on one side of the lower part of the cabinet 1, and the liquid level detection device is made of a transparent material. A cavity is provided in the rotating shaft 6, and a feeding groove 61 is provided at the upper end of the rotating shaft 6. The groove can be Add any batching, be provided with six nozzles 11 communicating with the cavity on the rotating shaft 6, wherein three nozzles 11 are equally arranged between the first crushing disc 5 and the second crushing disc 7, and the other three nozzles 11 It is evenly arranged between the second crushing disc 7 and the third crushing disc 8, and a heater 10 is respectively arranged on both sides of the bottom of the rotating shaft 6. The specific operation of this embodiment is as follows:

[0026] After the heater 10 is energized, the blower in the heater 10 blows the air into the heater, so that the air passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com