Spiral multisurface paint spraying device

A technology of spiral and spiral slideway, which is applied in the configuration or installation of nozzles, and can solve the problems of low painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

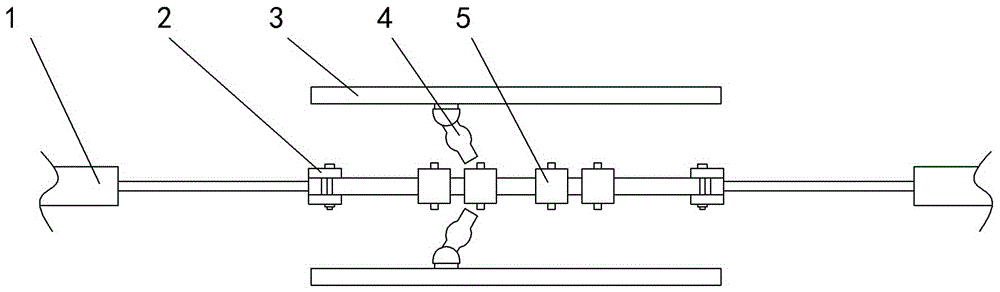

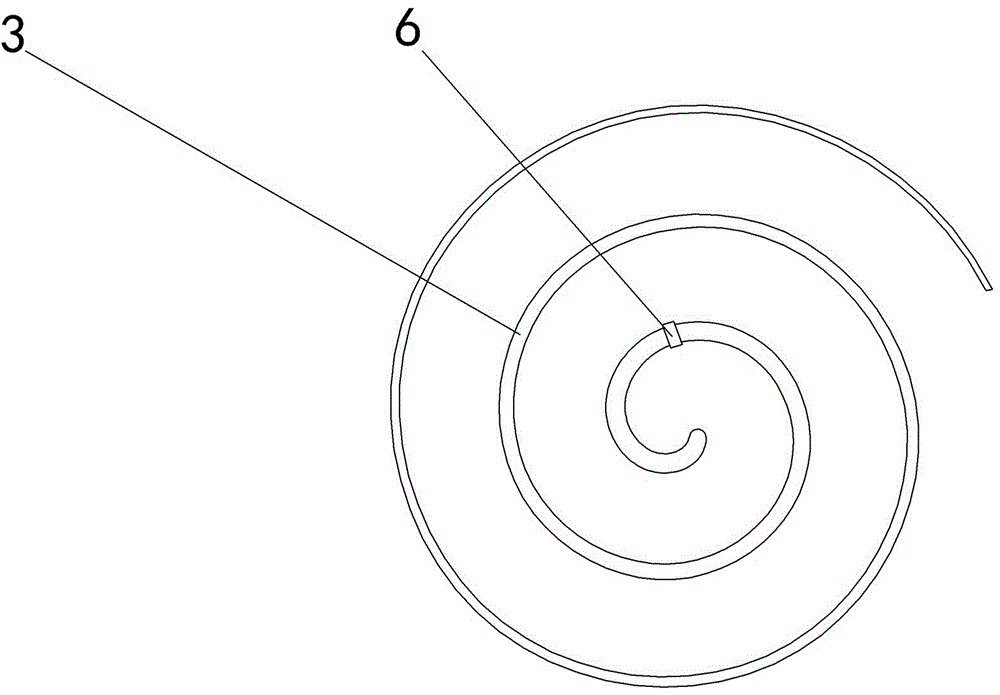

[0017] Embodiment: The spiral multi-faceted paint spraying device in this scheme is used for spraying paint on the door leaf, as shown in Figure 1, includes oil fixing frame, paint pump and two hydraulic cylinders 1, and the output end of hydraulic cylinder 1 is equipped with for clamping The fixture 2 of the door leaf, the fixture 2 includes a base plate and two splints, the two splints are slidingly connected with the base, and the base is welded on the output end of the hydraulic cylinder 1, and the two splints are provided with adjusting bolts. The clamps 2 on the two hydraulic cylinders 1 respectively clamp the two ends of the door leaf in the length direction. The movement path of the door leaf is located on the center line between the two spiral slides. The paint roller 5, the spiral slideway is located in the thickness direction of the door leaf, the paint roller 5 is located in the width direction of the door leaf, and the hydraulic cylinder 1, the spiral track and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com