Precast concrete culvert pipe, precast utility tunnel and maintenance method of utility tunnel

A technology of prefabricated concrete and comprehensive pipe gallery, which is applied in water conservancy projects, artificial islands, road bottom layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

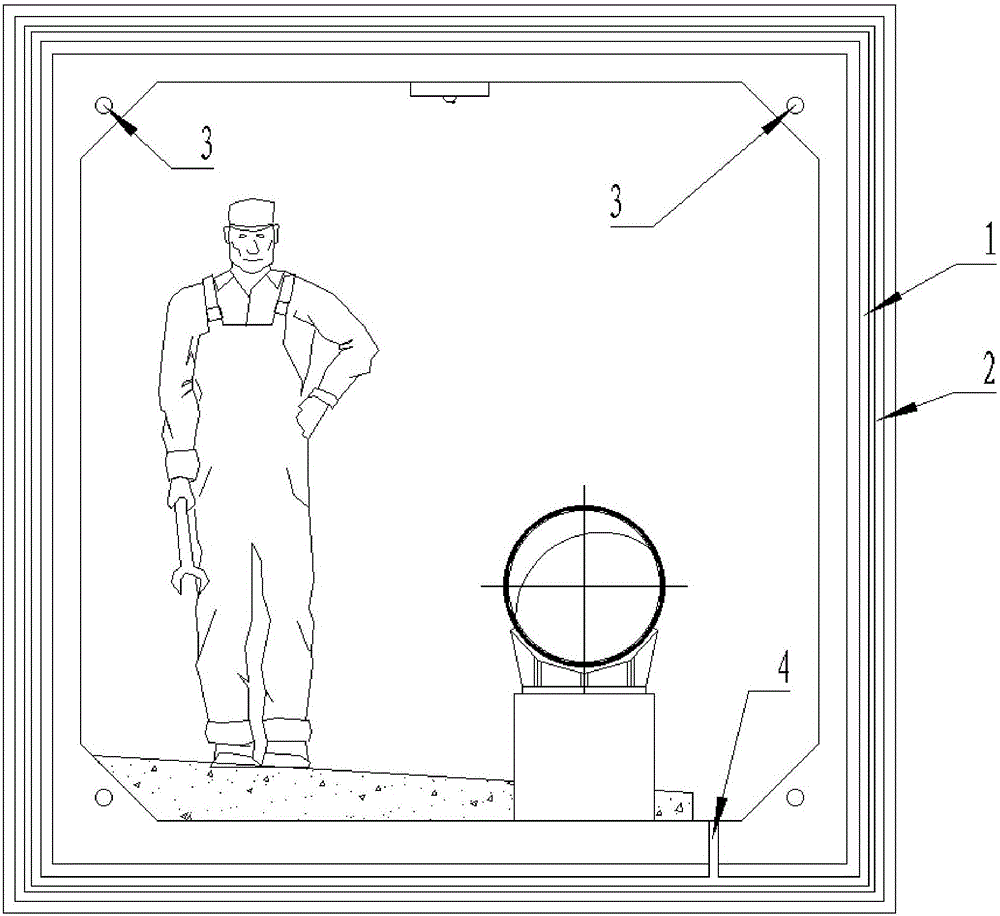

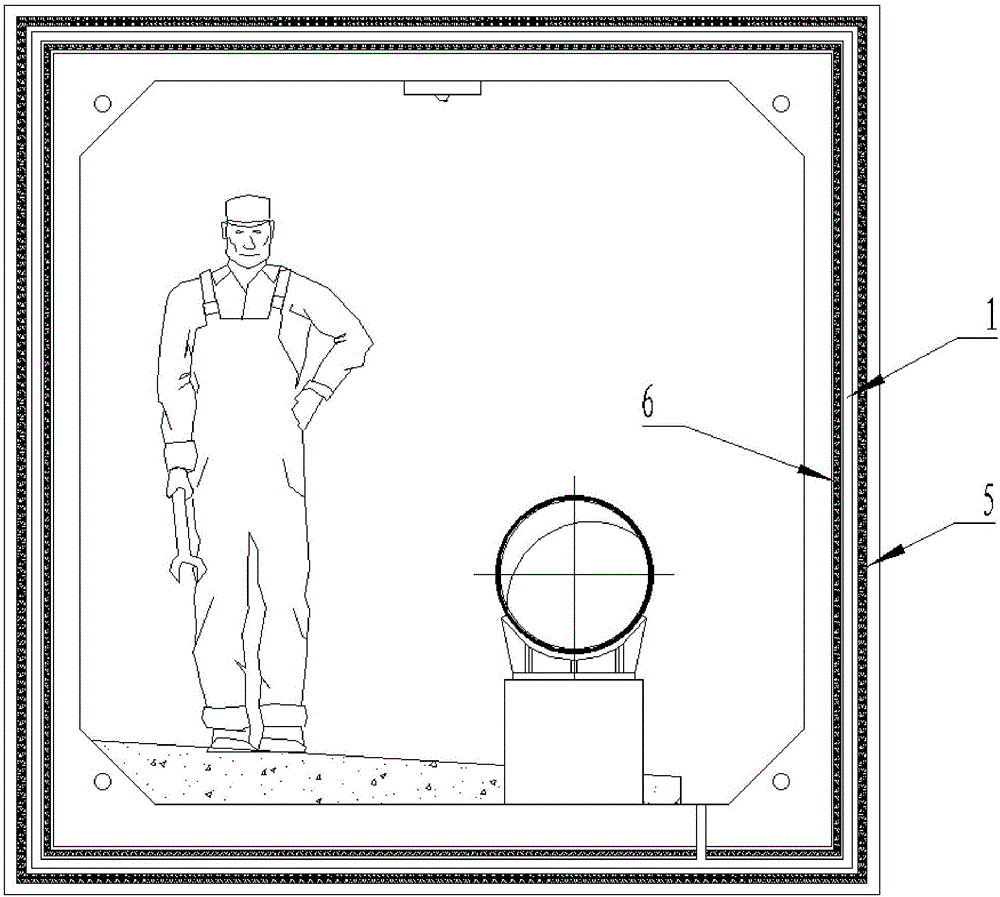

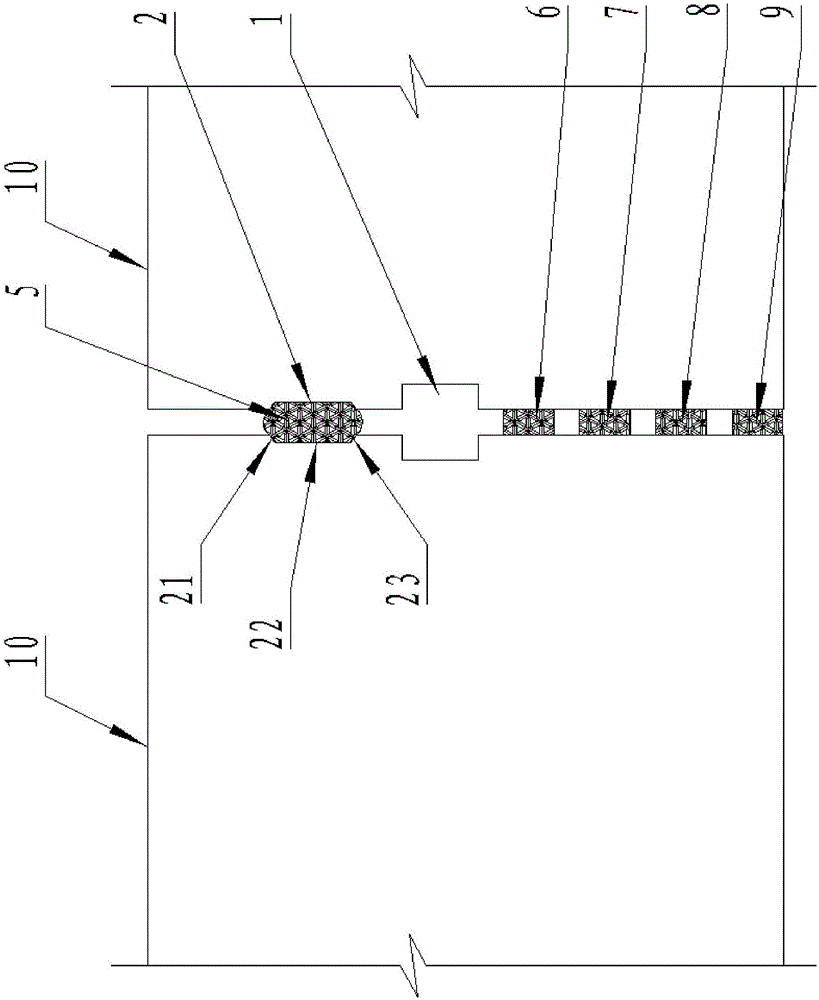

[0032] A prefabricated concrete culvert pipe, the prefabricated concrete culvert pipe has a waterproof drainage structure on both ends of the annular end surface, and the waterproof drainage structure includes a drainage groove 1 and a sealing strip installation groove 2 arranged along the circumference of the prefabricated concrete culvert pipe. Both the water tank 1 and the sealing strip installation groove 2 are arranged along the circumference of the prefabricated concrete culvert, the sealing strip installation groove 2 is located between the drainage groove 1 and the outer surface of the prefabricated concrete culvert, and the drainage groove 1 is connected to the prefabricated concrete cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com