Self-stress buckling-resistant support for threaded connection and assembly method thereof

A technology of anti-buckling support and screw connection, which is applied in the direction of earthquake resistance, building material processing, building types, etc., can solve the problem of section waste and achieve the effect of fully yielding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

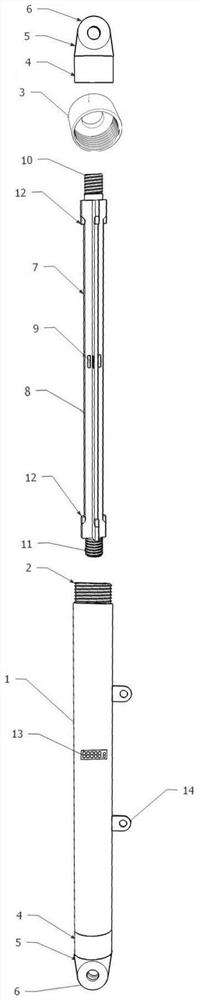

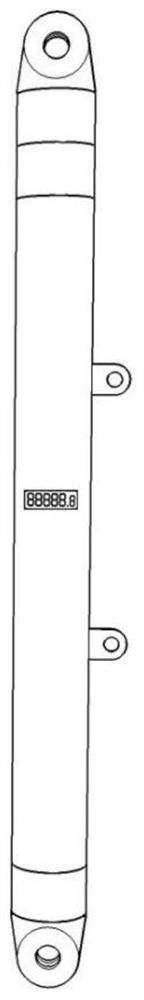

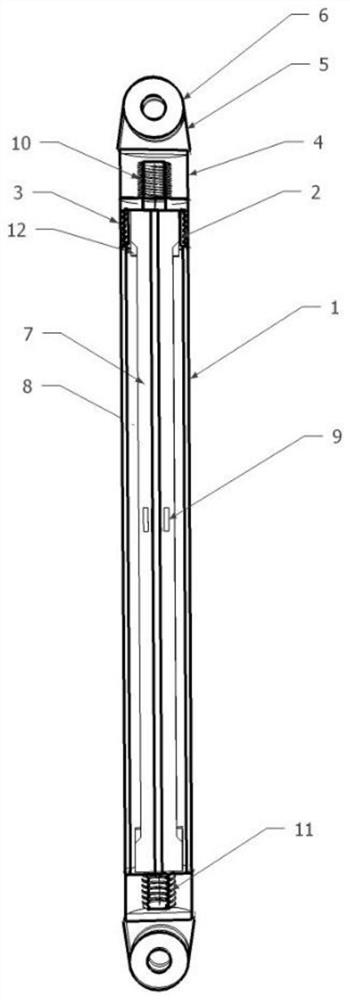

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0030] The self-stress buckling-resistant support for threaded connection of the present invention includes an outer component mainly providing restraint, a core component providing bearing capacity, an end component providing connection function and a threaded connection component applying prestress. The difference between the support of the present invention and the common buckling-constrained support is that the outer sleeve, as an external component, can bear the load without affecting the lateral restraint effect on the core cross-shaped steel support. The characteristic of pressure instability, and also has the mechanical properties of ordinary steel support full-section yield under tension, this support member can provide a more economical and practical support deepening scheme for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com