Shoe last two-section development method

A two-stage, shoe last technology, applied in shoe lasts, footwear, applications, etc., can solve the problems of increasing repetitive work and material costs, inconvenience in the overall design and development of shoe lasts, and inconvenient matching and selection, etc., and achieve savings. Material cost and labor cost, convenient and flexible selection of matching combinations, and the effect of improving design and development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

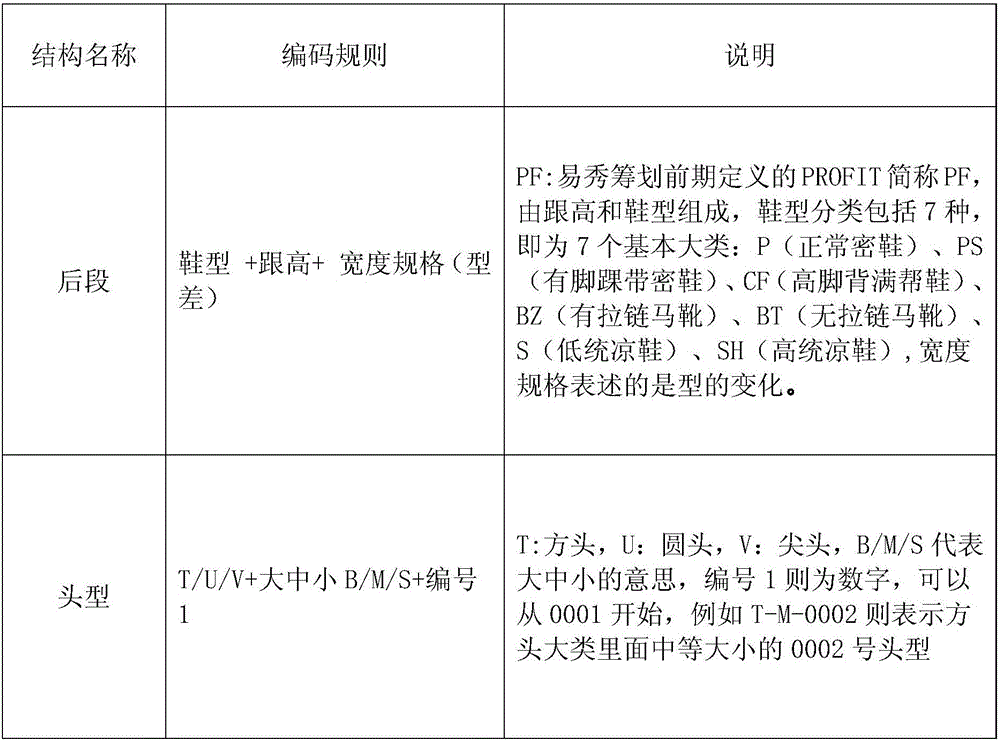

[0009] The present invention is a two-stage development method for a shoe last. The shoe last is divided into two sections, the back section and the head shape. The joint area is located at the connecting line between the first metatarsal and the fifth metatarsal in the shape of the foot. The rear section is classified according to shoe type, including high-cut sandals, low-cut sandals, riding boots with zipper, riding boots without zipper, and ankle straps. Shoes, normal close-fitting shoes, and high-instep full-top shoes have seven large series of rear sections. The head types are classified according to shape, including square toe, round toe, and pointed toe. The seven large series of rear sections are combined with three One-to-one arbitrary mutual matching of large series of head shapes to form a complete shoe last. The seven large rear series and the three large head series can also be appropriately expanded or changed to increase the possible variable rear series or lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com