Power transmission assembly of model airplane

A power transmission and power group technology, applied in the field of model aircraft, can solve the problems of difficult maintenance, easy damage, large power gear group, etc., and achieve the effect of reducing weight, reducing damage and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

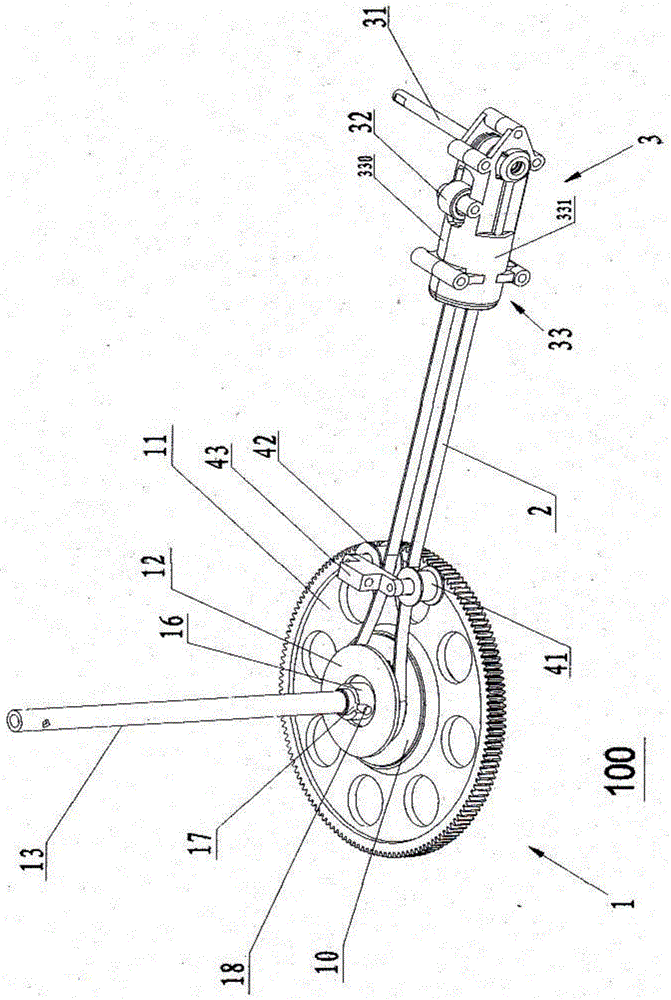

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] The power transmission assembly 100 of the present invention is installed in the fuselage body and the tail body of the aircraft model to constitute the power part of the aircraft model. It includes a power group 1, an empennage transmission unit 3 and a transmission member, and the empennage transmission unit 3 and the power group 1 are installed at both ends of the transmission member respectively. The work of the empennage transmission unit 3 is driven by the power pack 1 .

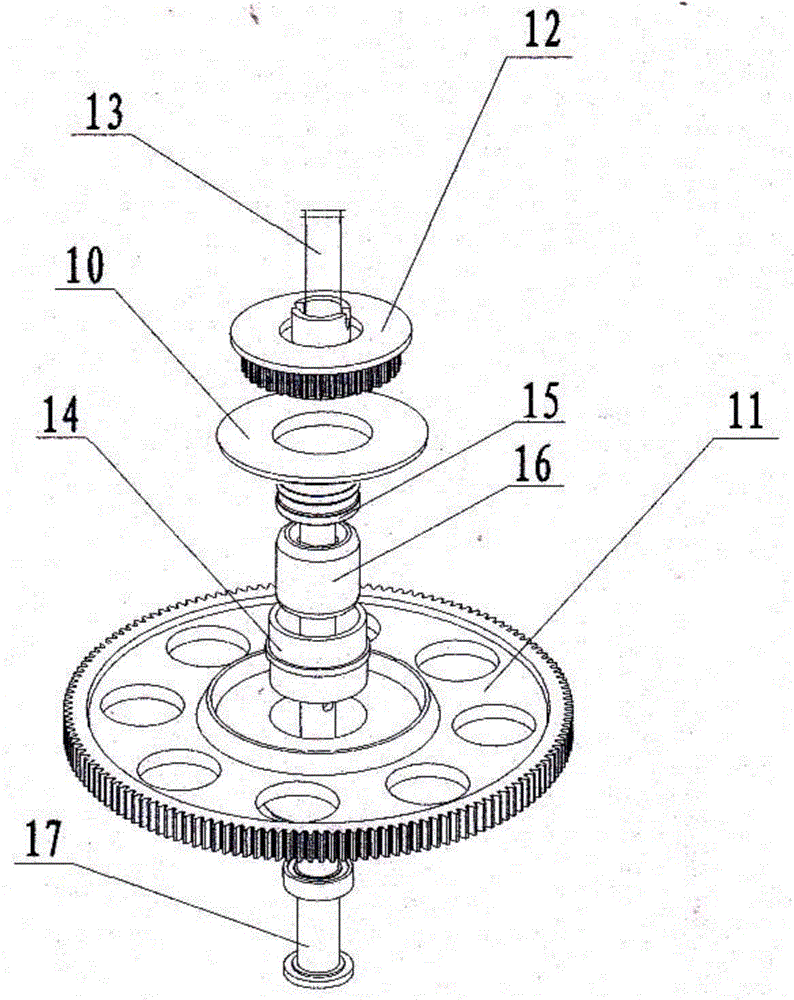

[0019] Power group 1 comprises motor bull gear 11, driving pulley 12, driving pulley cover 10 and main shaft 13, and main shaft 13 runs through motor bull gear 11, driving pulley 12 and driving pulley cover 10. The driving pulley 12 is placed on the driving pulley cover 10 and is installed in the motor bull gear 11, and the rotation of the whole power mechanism is driven by the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com