Combined Drill Bit for High Jet Mixing Cement and Soil Pile

A cement-soil pile and combined technology, which is applied in the direction of drill bit, earth square drilling, sheet pile wall, etc., can solve the problems of no inspection hole, poor ground adaptability, mud inclusion phenomenon, etc., so as to improve construction efficiency and stratum adaptability Strong and reduce the effect of drilling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

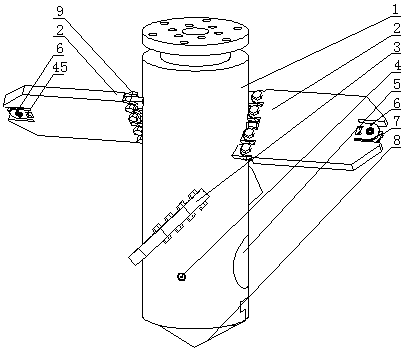

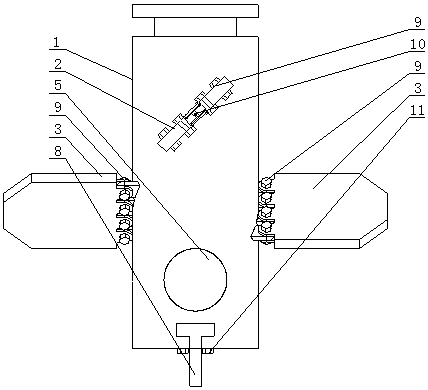

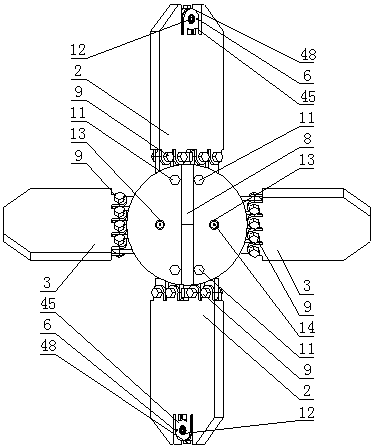

[0050] Embodiment 1: as figure 1 , 2 , 3, a combined drill bit suitable for high-jet mixing cement-soil piles, it includes a drill body 1 that is hollow cylindrical and has a built-in air path and a slurry path. One first stirring fin 2 and two second stirring fins 3, the first stirring fin 2 is located above the second stirring fin 3, the projections of the first stirring fin 2 and the second stirring fin 3 on the horizontal plane are perpendicular to each other; The lower part of the outer wall of the main body 1 is located below the second stirring fin 3 and is provided with a second nozzle 4 .

[0051] like Image 6 As shown, a drill pipe bolt hole 21, an air inlet hole 22 and a slurry inlet hole 23 are arranged on the top of the drill body 1, and a first stirring fin mounting plate 30 and a second stirring fin mounting plate are arranged on the outer wall of the drill bit body 1. 26. There are bolt holes on the first stirring fin mounting plate 30 and the second stirri...

Embodiment 2

[0066] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0067] like Figure 11 , 13 , 15, the basic structure of the first stirring fin 2 and the second stirring fin 3 adopts the rake-tooth structure, and the first stirring fin 2 includes a central steel rod 41 which is hollow and horizontally arranged, and on the central steel rod 41 Several longitudinally long steel rods 42 are arranged, the middle part of the longitudinally long steel rods 42 intersects the central steel rod 41 perpendicularly, the two ends of the longitudinally long steel rods 42 are provided with tapered tips, and on the outermost one longitudinally long steel rods 42 Two horizontal short steel rods 43 are provided, one end of the horizontal short steel rod 43 is connected with the vertical long steel rod 42, and the other end is provided with a tapered tip, and the horizontal short steel rod 43 is provided with a Longitudinal short s...

Embodiment 3

[0072] A method for using a combined drill bit suitable for high jet mixing cement-soil piles, comprising the following steps:

[0073] (1) Determine the diameter of the drill according to the design documents. If there is a stirring fin with a diameter that meets the requirements after being connected to the drill body 1, then directly select it. If there is no stirring fin of suitable size to choose from, the stirring fin that meets the requirements can be manufactured without reprocessing the entire drill bit.

[0074] (2) Judging the softness and hardness of the local stratum according to the survey report. If the formation is soft, the first nozzle 7 can be adjusted to spray upwards; if the formation is moderately soft and hard, the first nozzle 7 can be adjusted to spray horizontally; if the formation is hard, the first nozzle 7 can be adjusted to spray downward.

[0075] (3) Connect the drill pipe 46 and the drill bit body through the bolt 47, and connect the grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com