Guide structure of spraying system

A technology of spraying system and deflector, which is applied in the direction of capturing or killing insects, application, animal husbandry, etc. It can solve the problems of low flexibility in the use process, poor spray effect, complex structure, etc., and achieve airflow pressure Sufficient, simple structure, enhance the effect of spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

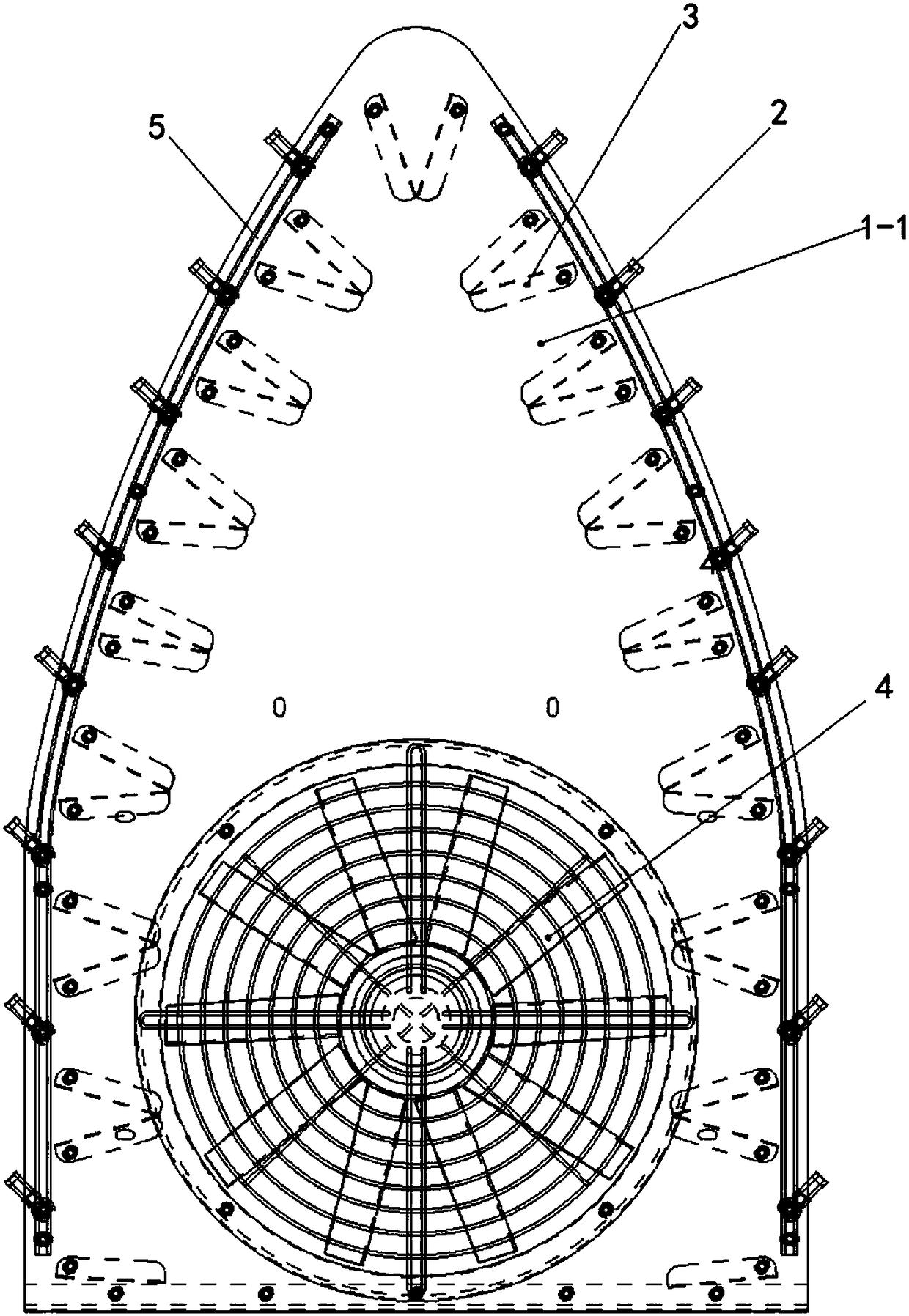

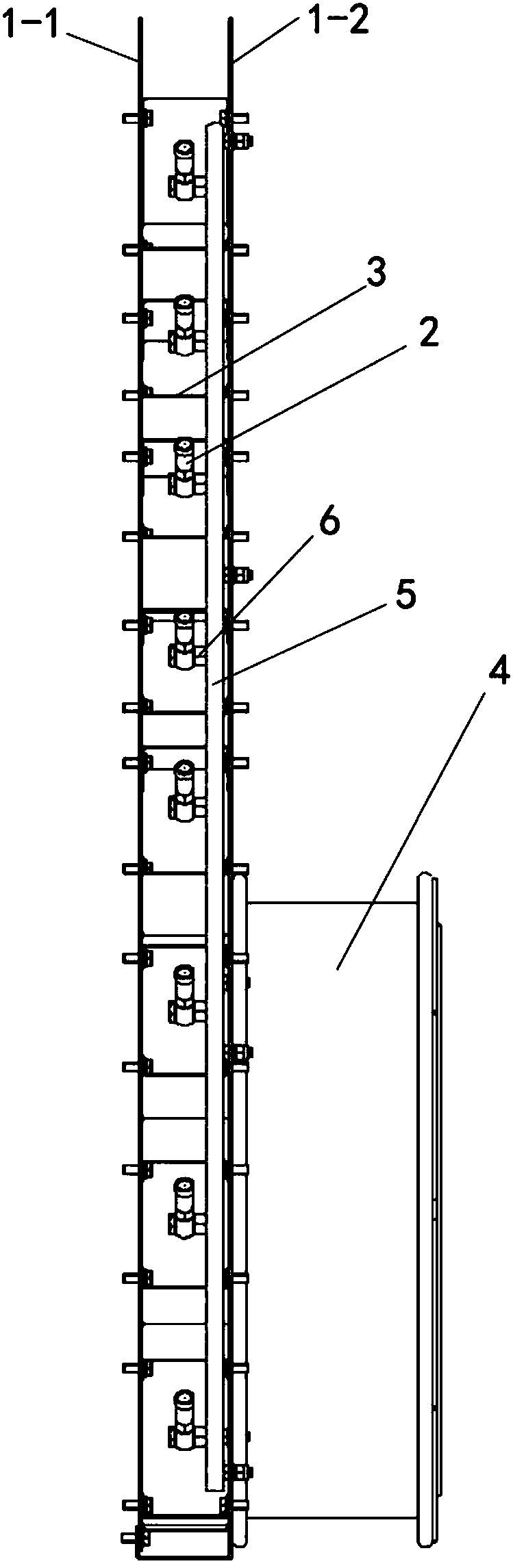

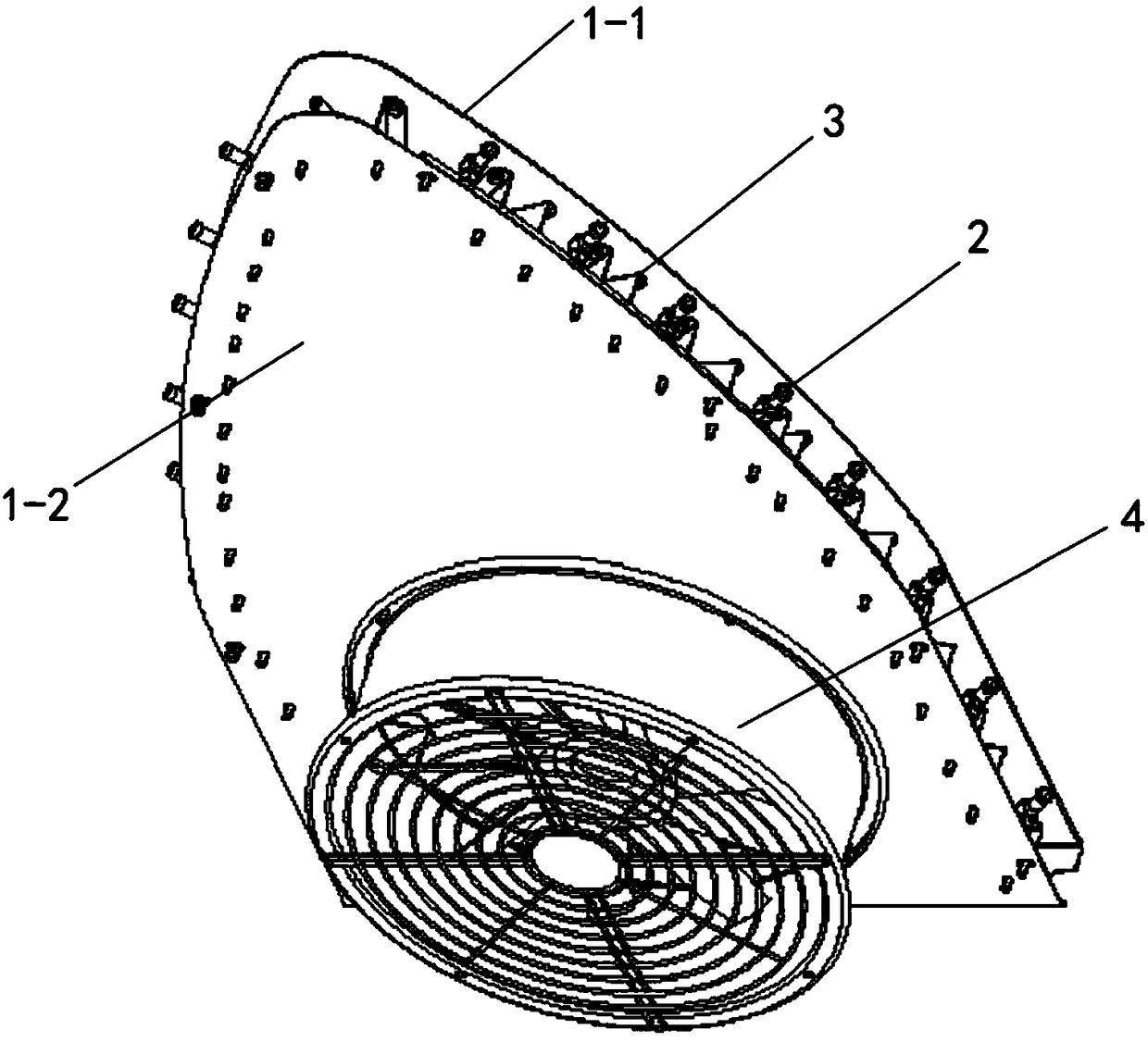

[0018] Such as Figure 1~3 As shown, a flow guide structure of a spray system includes a wind guide cover, a fan 4, an infusion pipeline 5, and a nozzle 2, and the wind guide cover includes a front cover 1-2 and a rear cover 1-1, and the front cover 1-2 Both the lower half of the cover plate 1-2 and the rear cover plate 1-1 are quadrangular, and the upper half is triangular. Adopting this structure can effectively improve the distribution uniformity of the airflow inside the windshield, especially to ensure the upper airflow Have enough pressure to ensure the overall spray effect. The lower part of the front cover 1-2 is provided with the fan 4, the nozzle 2 communicates with the infusion pipeline 5, and a plurality of "V"-shaped deflectors 3 are distributed inside the wind deflector. The plate 3 is distributed along the outer periphery of the wind deflector, and the top inside the wind deflector is distributed with a deflector 3, which also prevents strong air from blowing o...

specific Embodiment 2

[0019] The difference between this embodiment and Embodiment 1 is that: it also includes an air guide tube assembly, which is distributed behind each of the nozzles 2; the air guide tube assembly includes a flexible bellows 7 and a sealing Plate 8; the bellows 7 in this embodiment adopts a plastic bellows for guiding the wind and ensuring that it can turn. between two adjacent deflectors 3, and seal the air outlet between two adjacent deflectors 3; the rear end of the spray head 2 is connected to the The inner chamber of bellows 7 front ends is combined. When in use, the airflow inside the air guide hood can only be blown out through the bellows 7. When adjusting the direction of the nozzle as required, the plastic bellows can be bent to ensure that the wind direction is consistent with that of the nozzle and significantly improve the spraying effect.

specific Embodiment 3

[0020] The difference between this embodiment and Embodiment 1 is that the deflector is in a "U" shape, and a control valve is provided between the nozzle and the connecting pipe. Through the control valve, each The direction of the nozzle flow is controlled or closed to prevent the waste of liquid medicine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com