Three-in-one integrated test system for preventing condensation inside vibration table

A test system and a three-integrated technology, applied in the field of mechanical environment test equipment, can solve the problems of frost and condensation on electric vibration tables, achieve the effect of solving frost and condensation, avoiding frost and condensation, and achieving low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

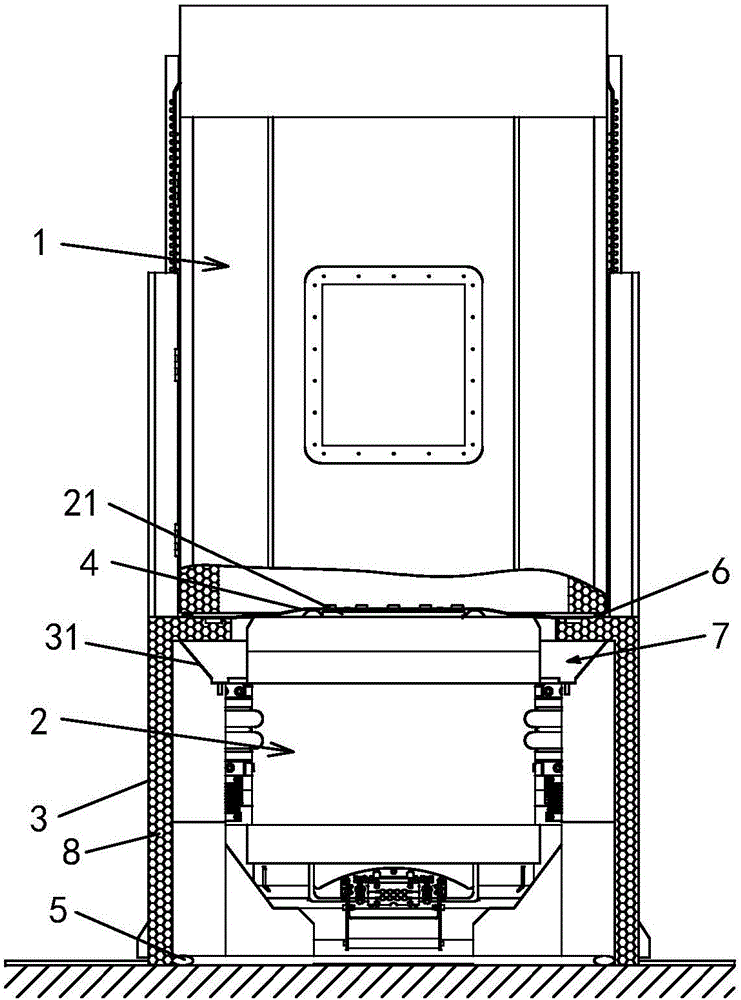

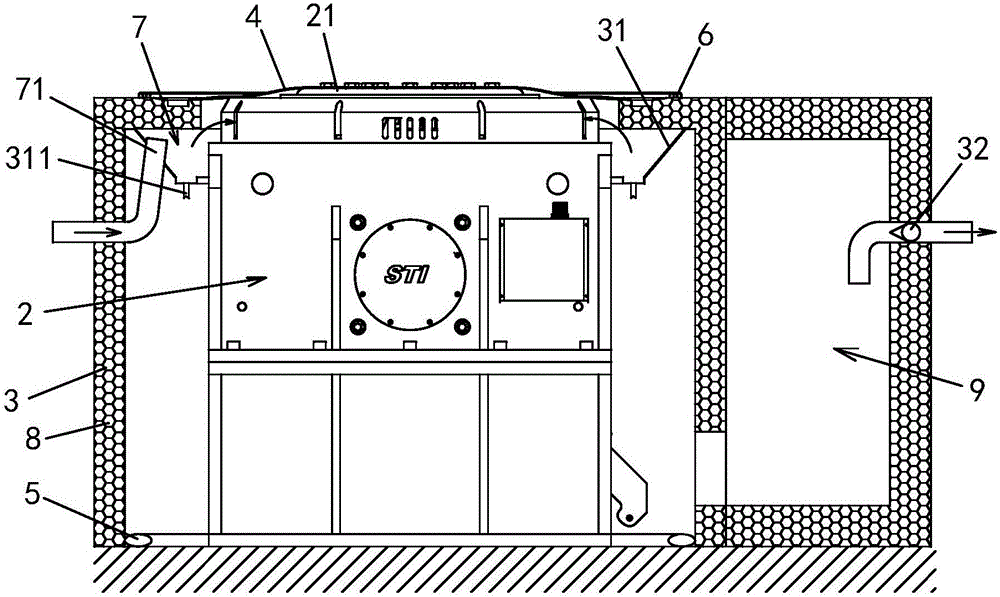

[0021] Example: see Figure 1-2 Shown:

[0022] A three-comprehensive test system for anti-condensation inside the vibration table, see figure 1 As shown, it includes a temperature control box 1 and an electric vibration table 2. The temperature control box 1 is placed on the electric vibration table 2, and the table 21 of the electric vibration table 2 extends into the temperature control box.

[0023] see figure 1 , figure 2 As shown, the outer cover of the electric vibrating table 2 is provided with an isolation cover 3, and the table top 21 of the electric vibrating table 2 stretches out from the top port of the isolation cover 3, between the top port of the isolation cover 3 and the table top 21 of the electric vibration table 2 The flexible membrane 4 is used to seal the connection, and the bottom end of the isolation cover 3 is sealed to connect with the ground with a sealed airbag 5, so that the inside of the isolation cover 3 becomes a pair of externally closed ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com