Photovoltaic battery assembly aluminum alloy joist

A photovoltaic cell and photovoltaic module technology, applied in photovoltaic power generation, electrical components, photovoltaic modules and other directions, can solve the problems of large gap between components and components, lack of limit measures, component falling off, etc., to improve construction efficiency, improve aesthetics, The effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

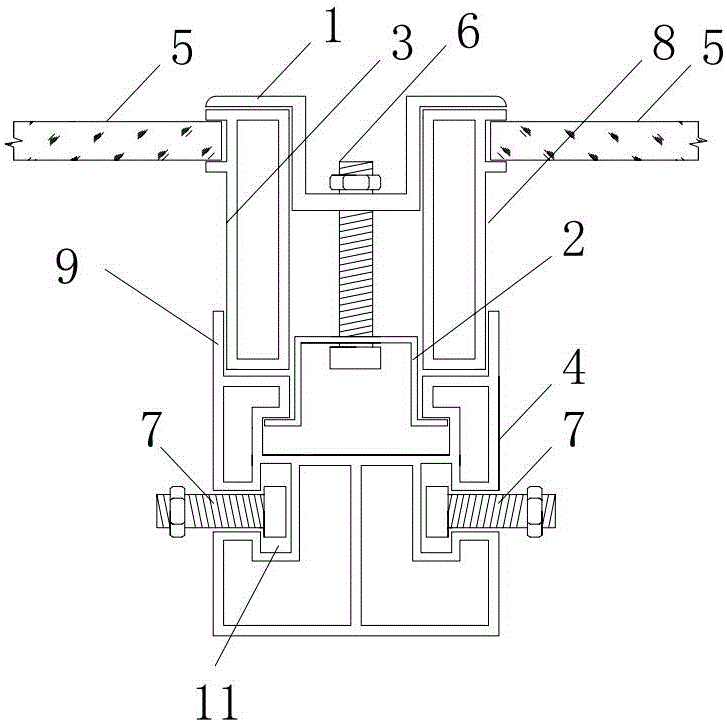

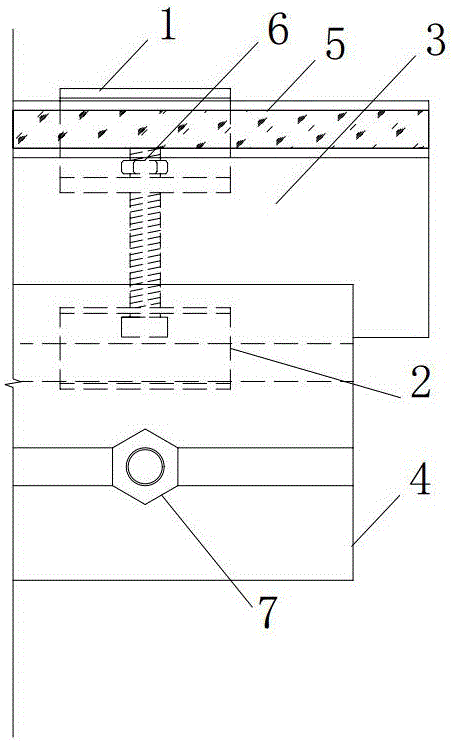

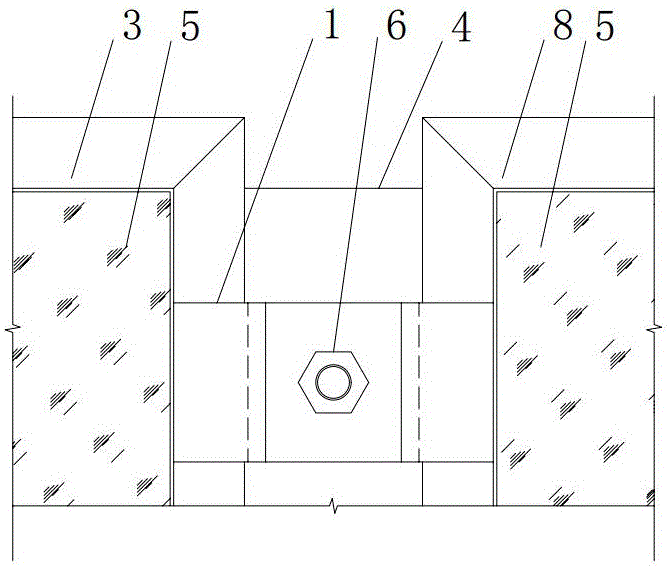

[0013] An aluminum alloy joist for a photovoltaic cell module described in Embodiment 1, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes the aluminum alloy joist 4 and the left photovoltaic module aluminum frame 3 and the right photovoltaic module aluminum frame 8 that cooperate with the aluminum alloy joist to limit the installation and clamp the solar panel 5, and the aluminum alloy joist The aluminum alloy lower buckle 2 is embedded in it, and the aluminum alloy lower buckle is fixedly connected with the aluminum alloy upper buckle 1 by stainless steel locking bolts 6, and the aluminum alloy upper buckle clamps the top and inner sides of the aluminum frames of the left and right photovoltaic modules. The side and limit the left and right photovoltaic module aluminum frames to form a certain installation distance; the top of the aluminum alloy lower buckle protrudes from the top of the aluminum alloy joist piece, and the two sides of the aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com