Down jacket sewing method

A down jacket and down technology, which is applied in the field of down jacket sewing, can solve the problems of down jackets such as easy lumps, cold, and aging of fabrics, and achieve the effect of uniform distribution of down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

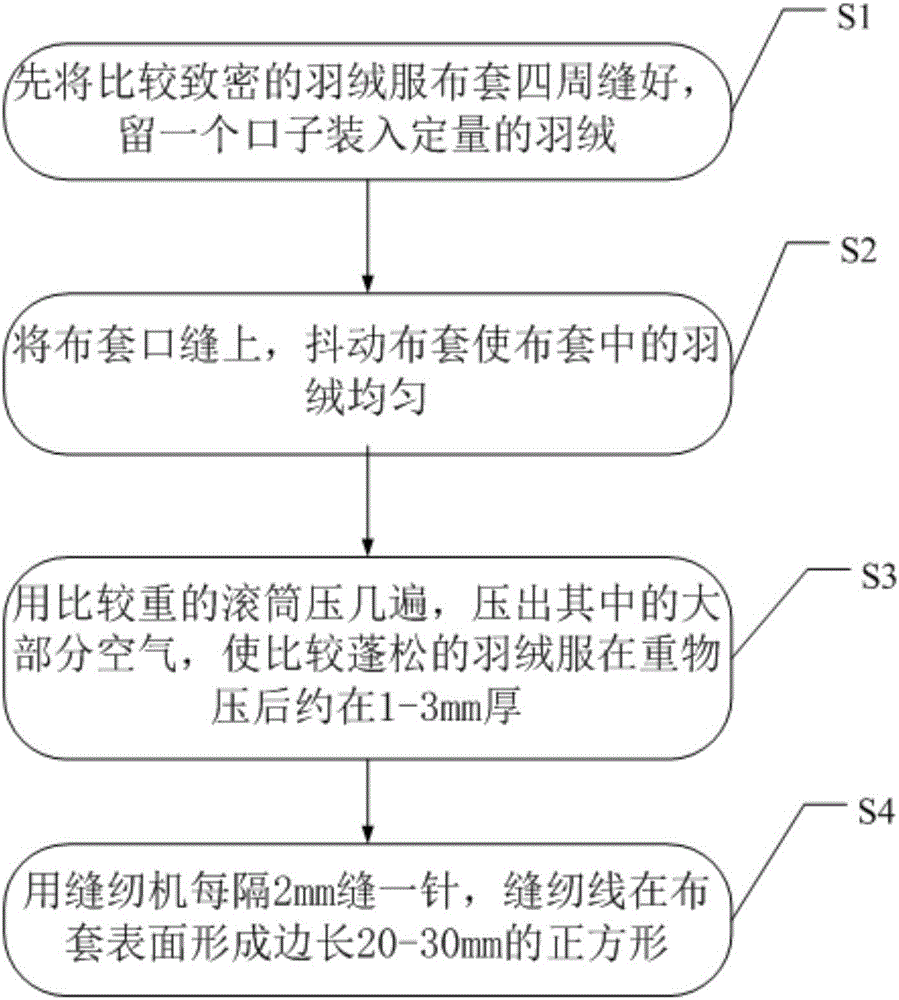

[0011] Down jacket sewing method of the present invention, as attached figure 1 shown, including the following steps:

[0012] S1: First sew the denser down jacket cover around, and leave a hole to fill in a certain amount of down.

[0013] S2: Sew the cloth cover, shake the cloth cover to make the down in the cloth cover even;

[0014] S3: Use a heavy roller to press several times to press out most of the air, so that the fluffy down jacket is about 1-3mm thick after pressing with heavy objects.

[0015] S4: Use a sewing machine to sew a stitch every 2mm, and the sewing thread forms a square with a side length of 20-30mm on the surface of the cloth cover.

[0016] Preferably, it also includes S5: after the sewing is completed, heat and dry the garment to complete the processing.

[0017] Sew a stitch every 2mm. Such dense needlework makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com