One-machine and multiple-head type dispersion machine

A multi-head type, dispersing machine technology, applied in the direction of mixers, mixers with rotating stirring devices, dissolving, etc., can solve the problems of affecting work efficiency, wasting time, cumbersome replacement of mixing heads, etc., and achieves wide application range and high work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

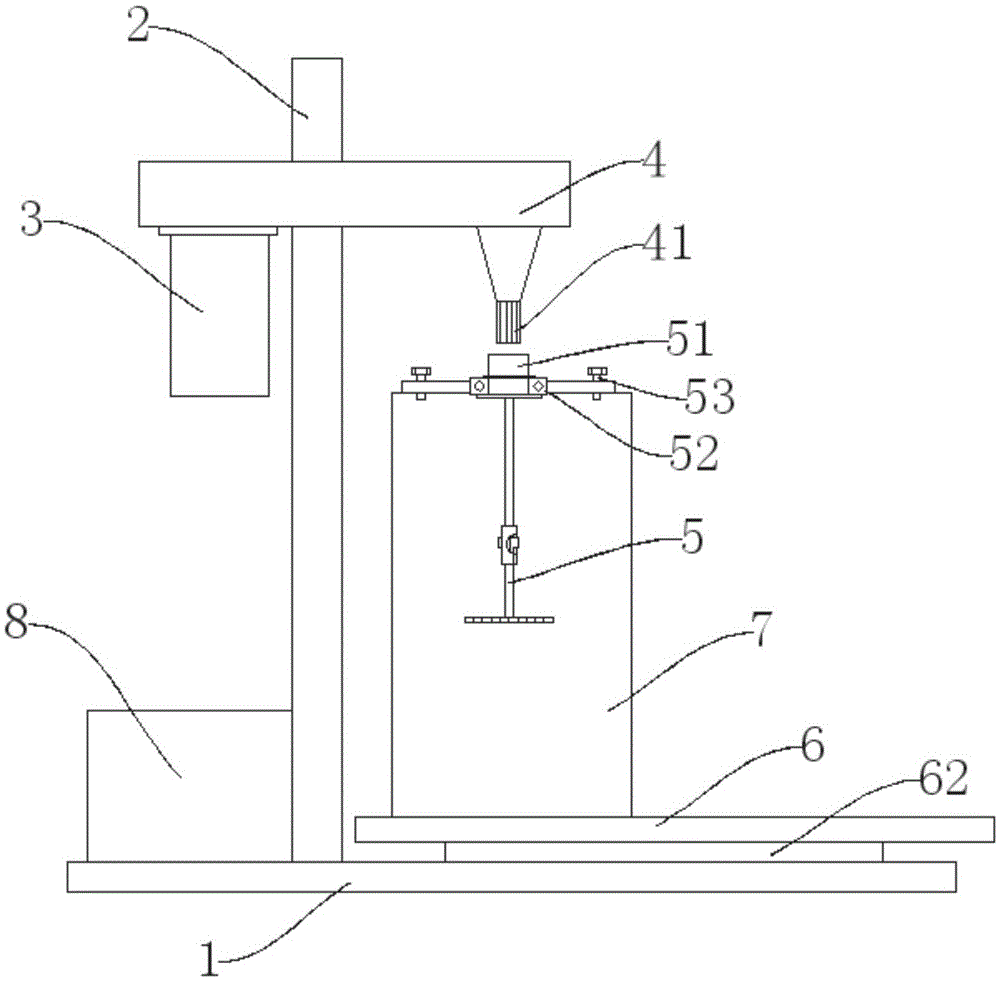

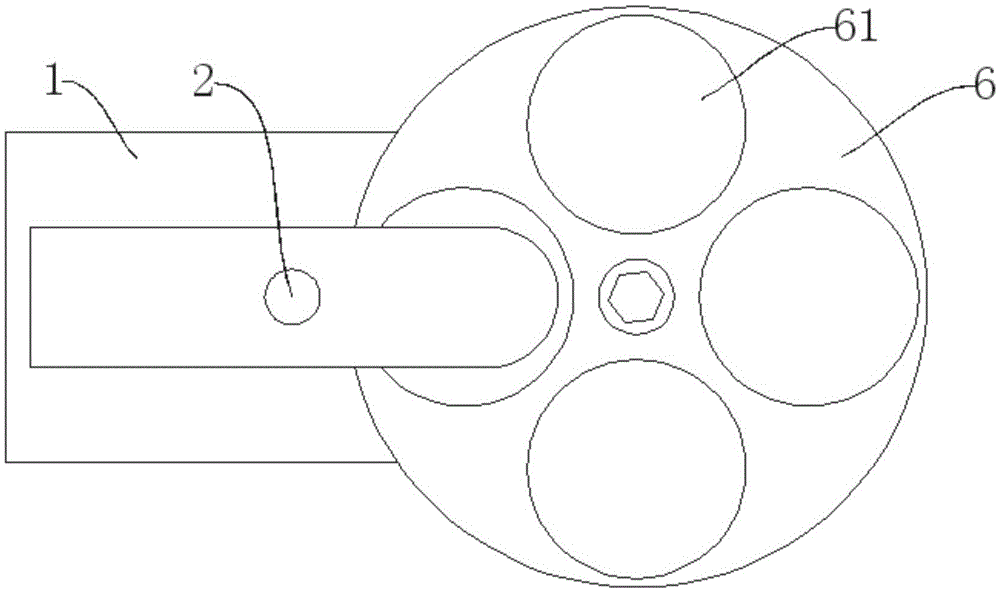

[0014] As shown in the figure, a kind of multi-head dispersing machine of the present invention comprises a base 1, a support frame 2, a body 4, a motor 3 and a container 7, and the body 4 is provided with a rotating head 41, and the The rotating head 41 is driven by the motor 3 to rotate at a high speed, the rotating head 41 is an external spline structure, the container 7 is provided with a stirring head 5, and the stirring head 5 includes a shaft, a shaft positioned below the shaft The mixing knife and the connecting sleeve 51 located above the shaft, the connecting sleeve 51 is fixed on the container 7 through bearings 52 and bolts 53, and the connecting sleeve 51 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com