Cover pressing device for automatic assembly line of EPS bearing

An assembly line and gland technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of deformation of dust cover, affecting the quality of dust cover, and failure to guarantee the flexibility of bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail.

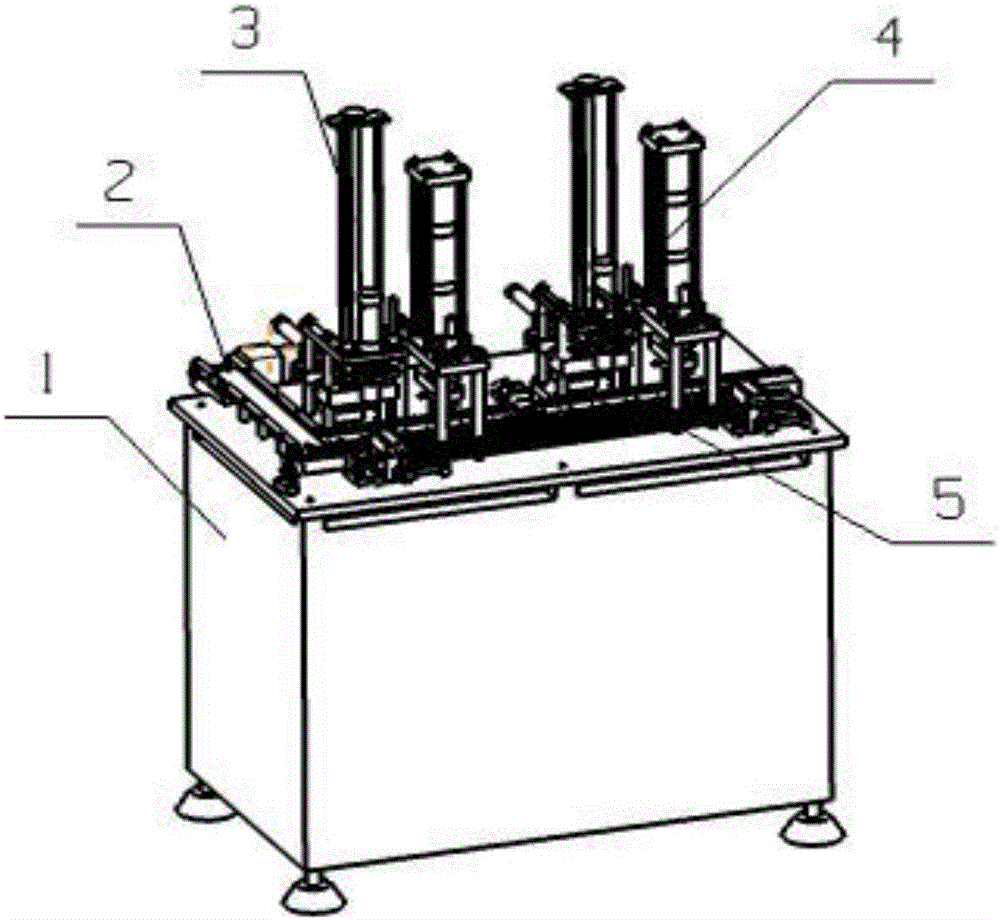

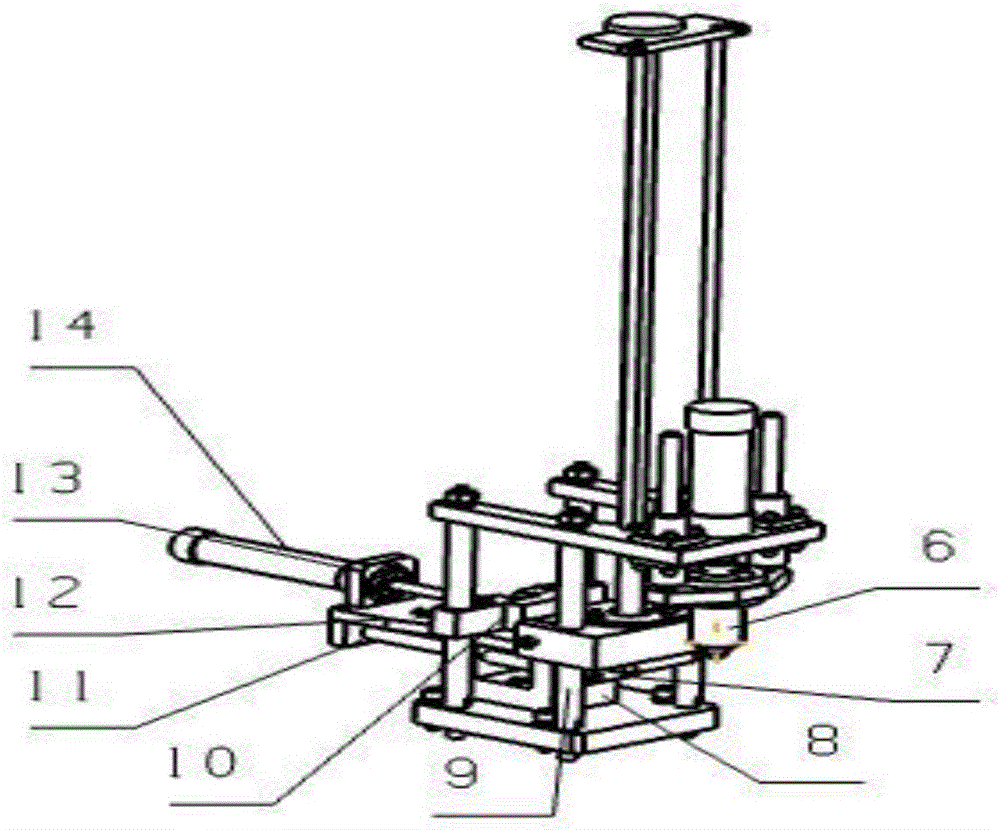

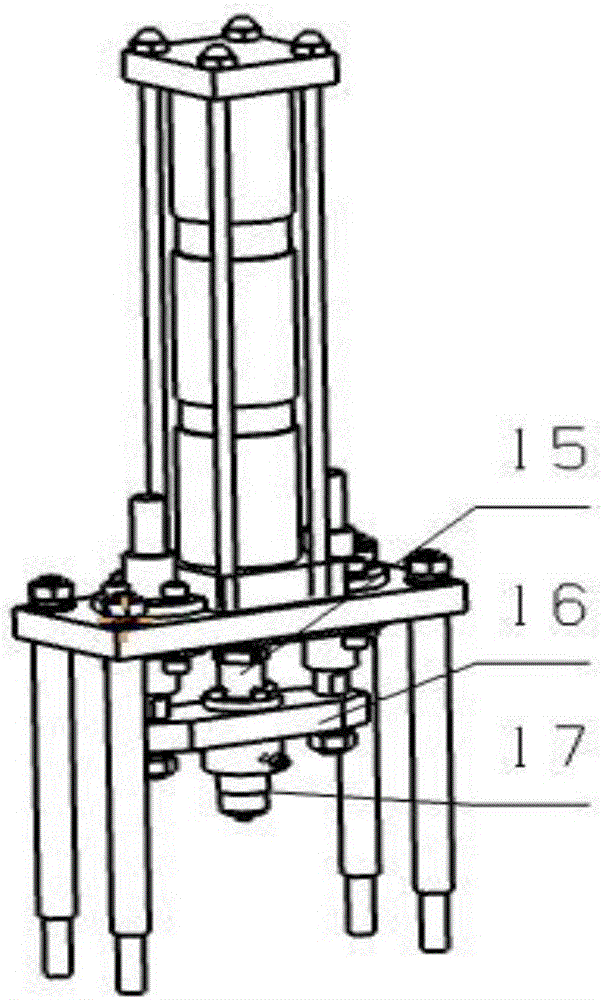

[0020] exist figure 1 Among them, a capping device for EPS bearing automatic assembly line, mainly consists of a base (1), a belt conveying mechanism (2), a cap feeding mechanism (3), a capping mechanism (4) and a fork conveying mechanism (5) Connection composition. The belt conveying mechanism (2) and the fork conveying mechanism (5) are arranged at the edge of the base (1), and the cap feeding mechanism (3) and the capping mechanism (4) are vertically arranged at the center of the base (1). The two cap feeding mechanisms (3) and the cap pressing mechanism (4) are fixed at vertical positions at intervals. During the working process, through the friction in the belt conveying mechanism (2), the EPS bearing of the previous process will be conveyed to the middle of the shift fork conveying mechanism (5). First, the shift fork (18) carries out axial movement, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com