A rubber punching station in an automatic punching and cutting stacked sheet swing device

An automatic punching and punching technology, applied in metal processing and other directions, to achieve the effect of improving practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

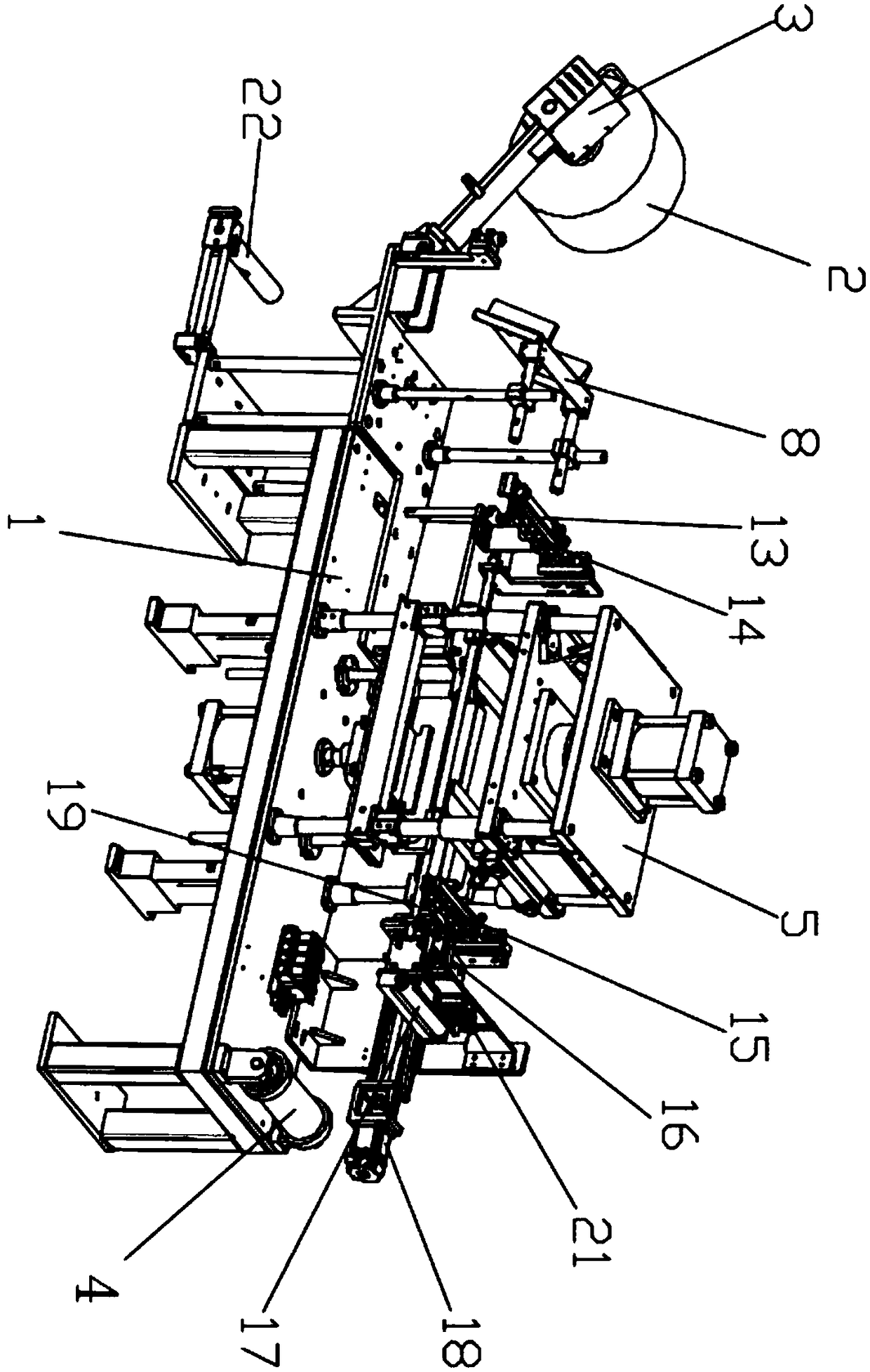

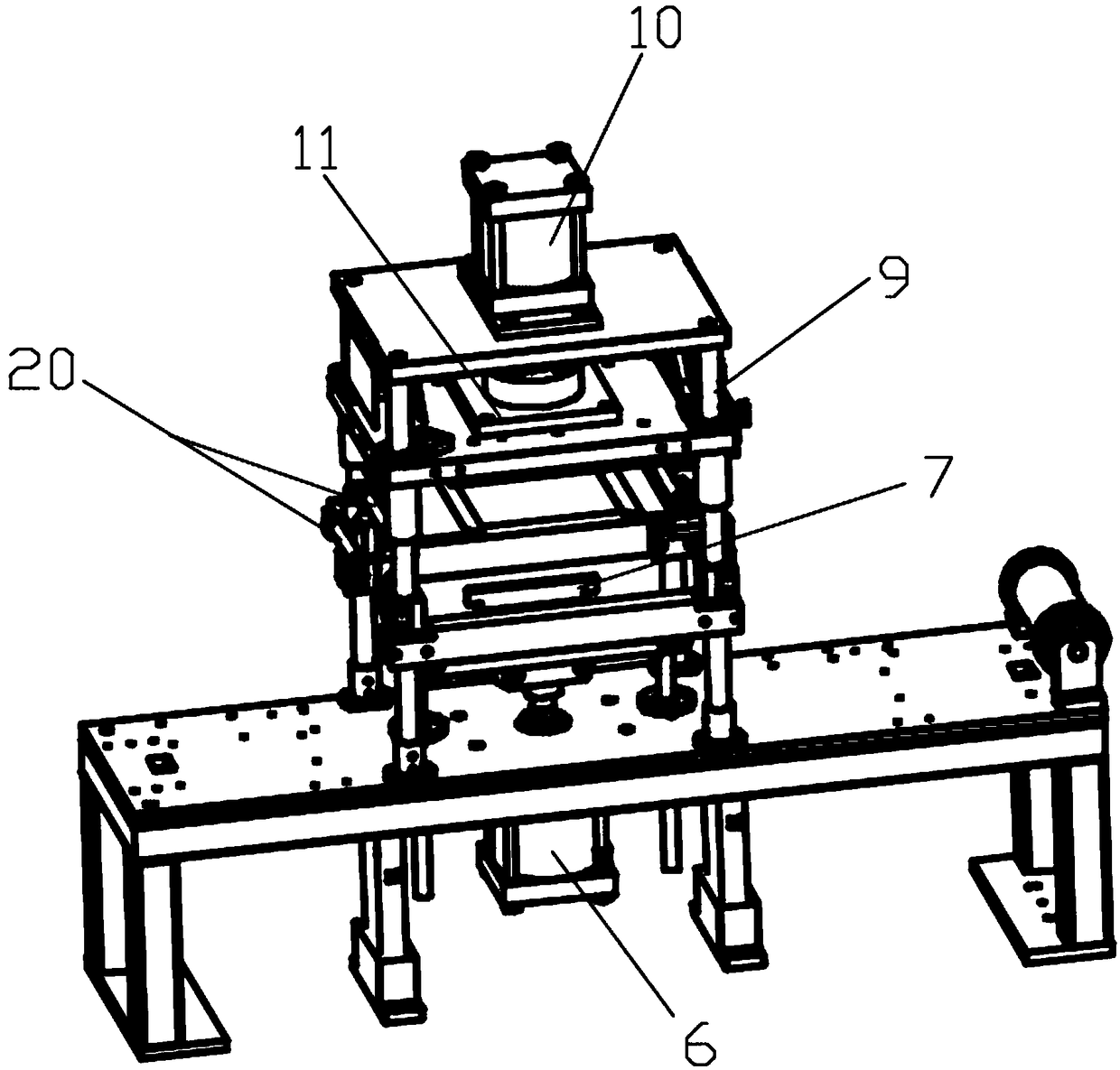

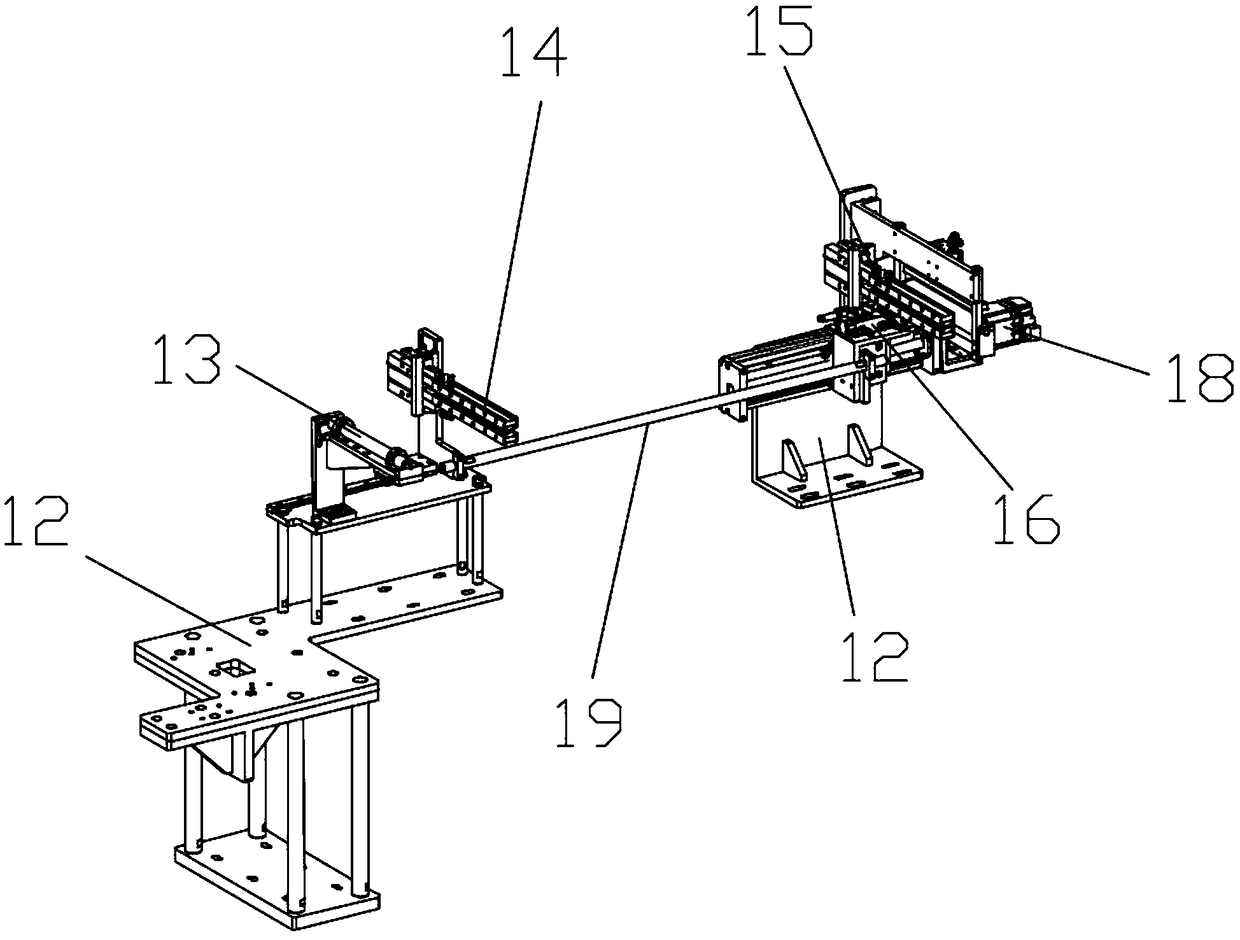

[0022] Such as figure 1 with image 3 The rubber blanking station in an automatic punching and stacking sheet swing device shown includes a bracket 1, a feeding roller, a feeding slide 8, a feeding roller 4, a cutting die 5, a conveying device and a lifting Cylinder 6, the discharge roller is connected to the discharge motor 3, the discharge motor 3 is connected to one end of the bracket 1 through the mounting bracket, and the feeding slide 8 is installed on the same end of the discharge roller Bracket 1, the described blanking roller 4 is installed on the other end of the bracket 1, and the described cutting mold 5 is installed on the bracket 1, and the described cutting mold 5 is located between the feeding slide 8 and the blanking roller 4 Between, the conveying device is installed on the rubber blanking support 1 between the loading slide 8 and the unloading roller 4, the conveying device passes through the cutting die 5, and the jacking cylinder 6 is installed At the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com