Titanium alloy skeleton skin structure welding device

A welding device and titanium alloy technology, applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of affecting the quality of the weld, being invisible, and wasting a lot of time, so as to ensure the quality of the weld and control the welding deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

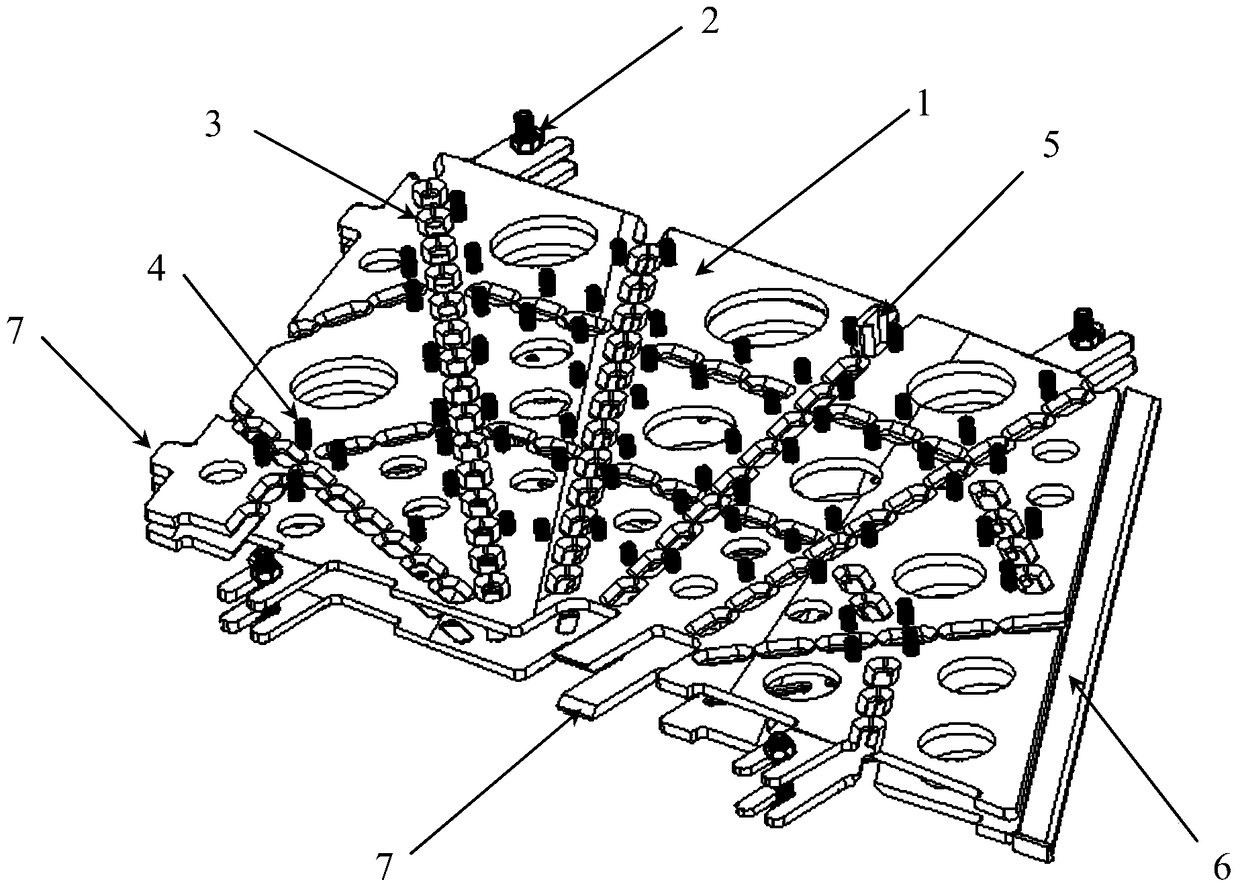

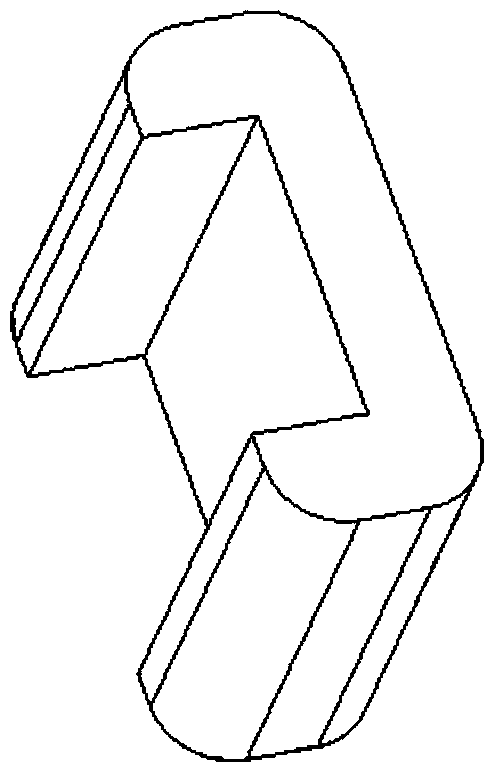

[0022] like figure 1 A welding device for a titanium alloy skeleton skin structure is shown, the device includes a profile pressing plate 1, a clamping member 2, a pressing piece 4, a marking block 5, and a plug block 6; two profile pressing plates are in four Under the action of the clamping member 2, the outer skin of the welded part is pressed and fixed; the pressing part 4 is installed on the profile pressing plate 1, and is used to clamp the skin and skeleton of the welded part; the plug 6 is placed on the welded part The upper and lower skin edges of the parts are used to prevent the edge skin welding deformation.

[0023] There are light-removing holes on the profile pressing plate 1, the inner profile of the profile pressing plate 1 adapts or coincides with the shape of the welded part, and the positioning datum 7 is set in two directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com