Printer capable of saving printing paper and control method thereof

A control method and printing paper technology, applied in printing devices, printing, etc., can solve the problems of wasting the first printing paper, waste, etc., and achieve the effect of saving printing paper and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

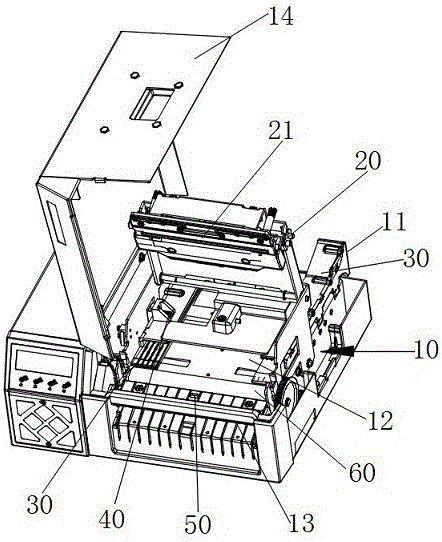

[0039] Please refer to figure 1 , a printer for saving printing paper, comprising a base 10 on which an openable cover 14 is arranged. The front end of the machine base 10 is provided with a paper outlet 13, the rear end of the machine base 10 is provided with a paper inlet 11, and a paper passage 12 is arranged between the paper outlet 13 and the paper inlet 11. . A rubber roller 60 is arranged on the machine base 10 , and the rubber roller 60 is arranged on a side close to the paper outlet 13 . An openable and closable printer on-core module 20 is provided inside the machine base 10 . The printer on-core module 20 has a thermal sheet 21 located above the rubber roller 60 . The rubber roller 60 cooperates with the thermal sheet 21 for printing and imaging. In addition, the rubber roller 60 also has the function of absorbing paper, that is, driving the movement of the printing paper.

[0040] Please refer to figure 1 , including a seam mark detection unit 40, an edge dete...

Embodiment 2

[0045]Using the above-mentioned printer, especially when only the edge detection unit 50 is set and the seam mark detection unit 40 is not set, specifically include the following steps:

[0046] S1, set the printing paper;

[0047] S2, the edge detection unit 50 detects whether there is printing paper;

[0048] S3, if the printing paper is not detected in step 2, then control the printing paper to advance, when the edge detection unit 50 detects the edge of the printing paper, control the printing paper to stop moving; if step 2 detects the printing paper, then control the printing The paper moves backwards or forwards and backwards multiple times, and when the edge detection unit 50 detects the edge of the printing paper, it controls the printing paper to stop moving.

[0049] S4, controlling the edge of the printing paper to move to the initial printing position.

[0050] Therefore, only one edge detection unit 50 is needed to realize no waste of the first sheet of printin...

Embodiment 3

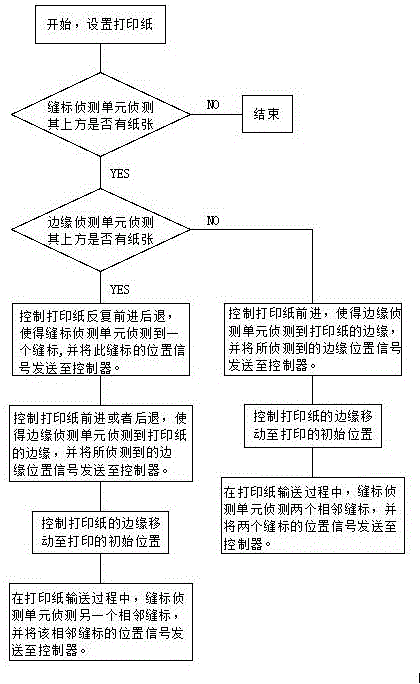

[0052] Please refer to figure 1 and figure 2 , using the above-mentioned printer, when the edge of the printing paper is located at the front end of the edge detection unit 50, such as when the printer core module 20 is loaded with paper after a paper jam, the edge of the printing paper protrudes from the outlet paper.

[0053] Specifically include the following steps:

[0054] S1, set the printing paper;

[0055] S2, when the seam mark detection unit 40 detects the paper and the edge detection unit 50 also detects the paper, then it is determined that the edge of the printing paper is located at the front end of the edge detection unit 50;

[0056] S3, controlling the printing paper to advance and retreat multiple times, the seam mark detection unit 40 detects one of the seam marks, and sends the seam mark position signal to the controller (not shown in the figure);

[0057] S4, the edge detection unit 50 detects whether there is paper above, and if paper is detected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com