Bogie bolster spring and wedge disassembling detection robot system

A robot system and bogie technology, applied in instruments, manipulators, measuring devices, etc., can solve the problems of high labor intensity and heavy weight, and achieve the effect of obtaining the height of the pillow spring and the precise pillow spring height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

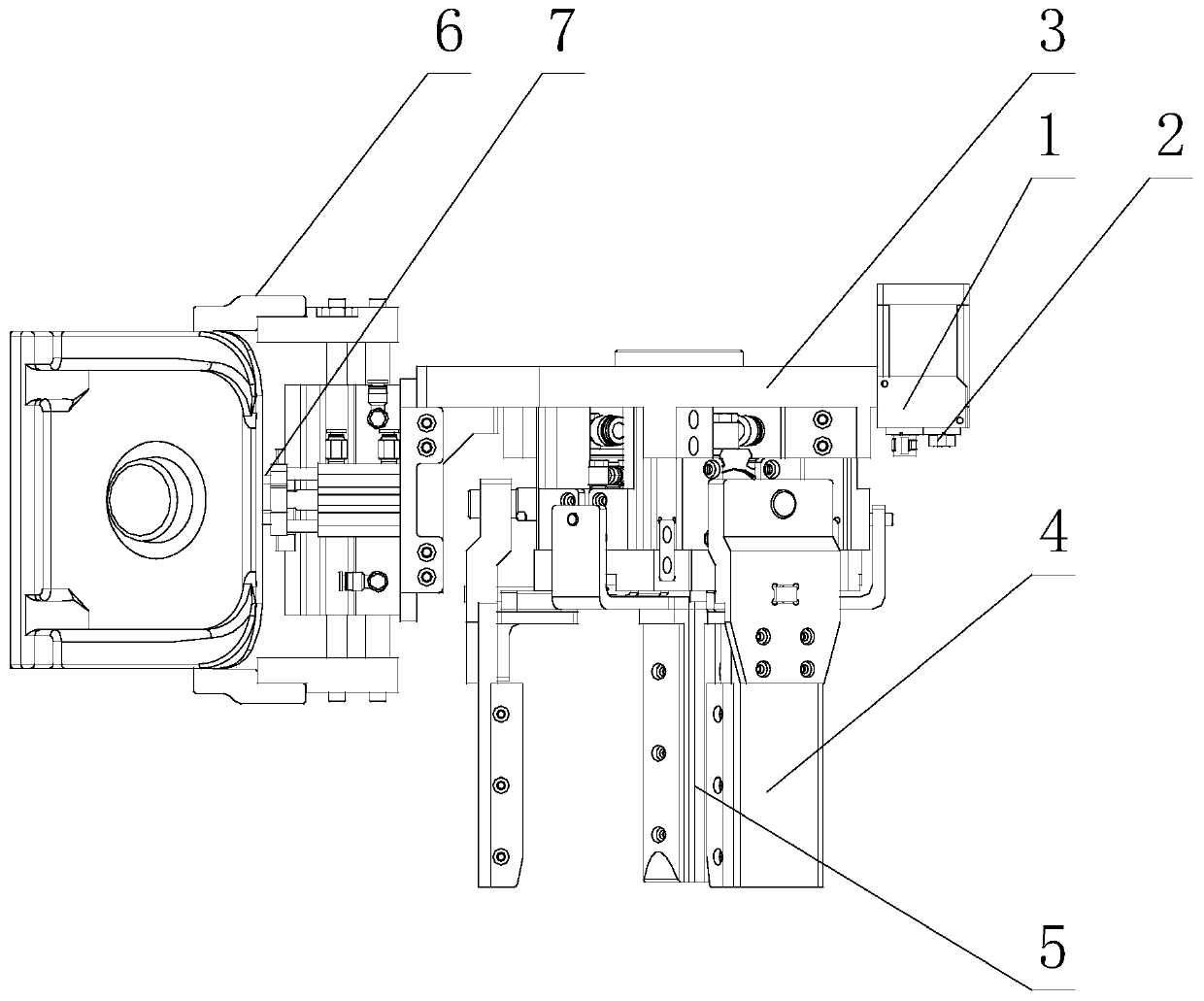

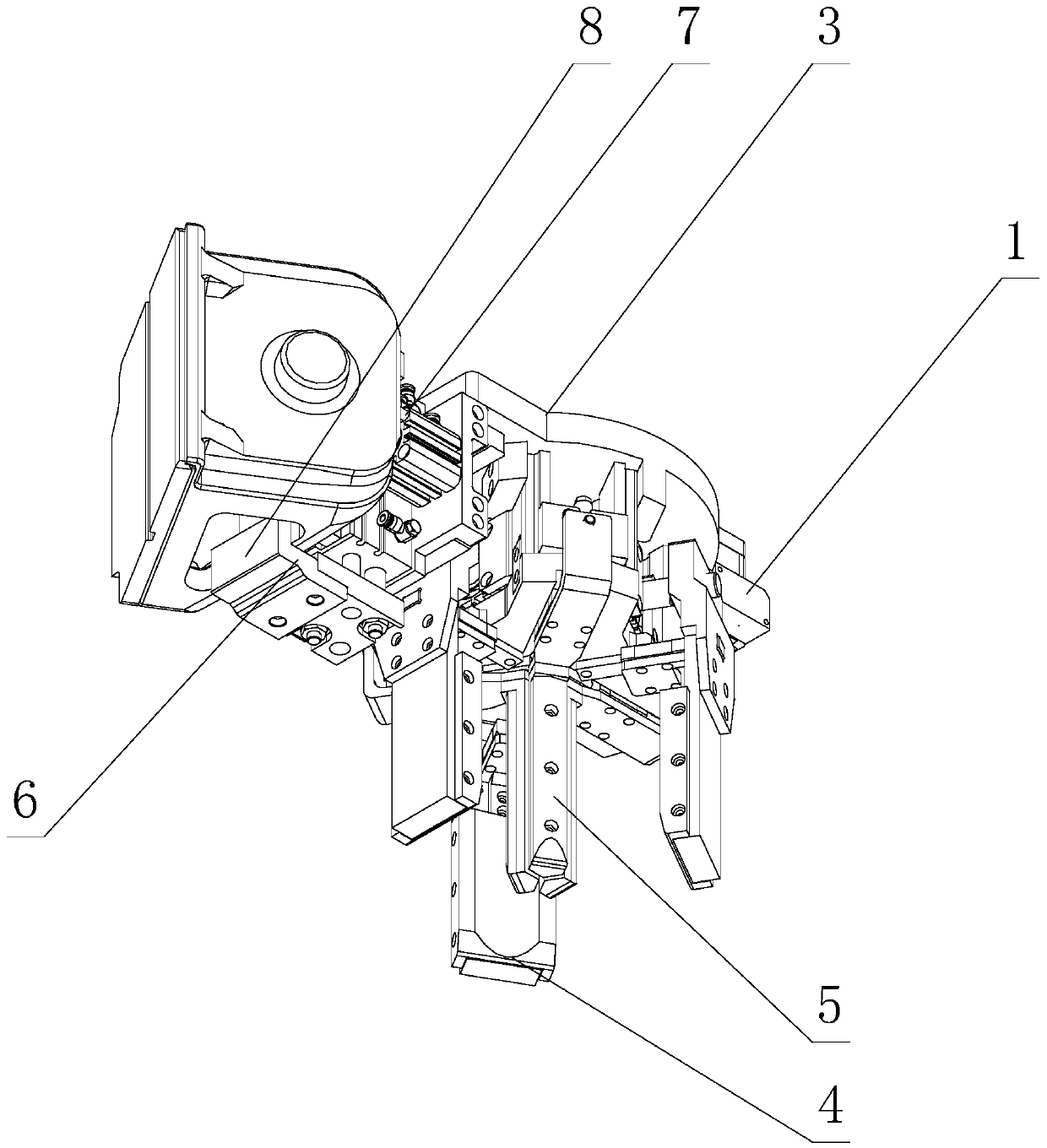

[0028] Such as figure 1 with figure 2 As shown, the bogie bolster spring and wedge decomposition detection robot system includes a decomposition device for decomposing the bogie, a manipulator, and a detection tool installed on the action end of the manipulator, and the manipulator is used to adjust the detection tool in the The position in the space, the detection tool includes a tool frame 3, and a distance measuring sensor 1 and a camera 2 are also installed on the tool frame 3, and the camera 2 is used to obtain the image information of the pillow spring and the wedge. Distance sensor 1 is used to detect the height of the pillow spring.

[0029]Aiming at the purpose of promoting the automation of bogie overhaul and production, this program provides a robot system that can detect wedges and pillow springs decomposed from the bogie. Specifically, the manipulator is used to realize the position transfer of the detection tool in space, so that the distance measuring sensor ...

Embodiment 2

[0032] Such as figure 1 with figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: in order to improve the working efficiency of the system, it is set that: the viewfinder end of the camera 2 faces the same direction as the signal acquisition end of the distance measuring sensor 1 . When this solution is used in practice, if the viewfinder and the signal acquisition end are all installed to face downwards in the working state, after the pillow spring is placed under the viewfinder and the signal acquisition end, the image information obtained by the camera 2 After identifying the positions of the inner and outer springs of the pillow spring, guide the laser ranging sensor 1 to complete the height measurement of the pillow spring in a translational manner.

[0033] Considering the adaptability of the camera 2 and the ranging sensor 1 to the position of the measured object, it is set that the manipulator is a multi-axis robot. Preferably, the mul...

Embodiment 3

[0035] Such as figure 1 with figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: as mentioned above, when the above system realizes the detection function, the state of the pillow spring and the wedge is the state of being unloaded from the bogie, in order to make the system After the detection is completed, it has the functions of pillow spring and wedge transfer, so as to avoid the increase of difficulty in overcoming mutual interference caused by setting too many manipulators when realizing automatic assembly line work. Fixing device, oblique wedge fixing device, the pillow spring fixing device is used to realize the fixing of the pillow spring on the manipulator, and the oblique wedge fixing device is used to realize the fixing of the oblique wedge on the manipulator. In actual use, after the pillow spring fixing device and the wedge fixing device complete the fixing of the corresponding pillow spring and wedge, the position transfer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com