A skylight noise reduction component and a method for determining its optimum opening

A technology for determining methods and components, applied to vehicle parts, roofs, transportation and packaging, etc., can solve problems such as fatigue, boredom, and reduced car comfort, and achieve the effect of suppressing wind vibration noise and suppressing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the following further describes the present invention with reference to the accompanying drawings and specific embodiments.

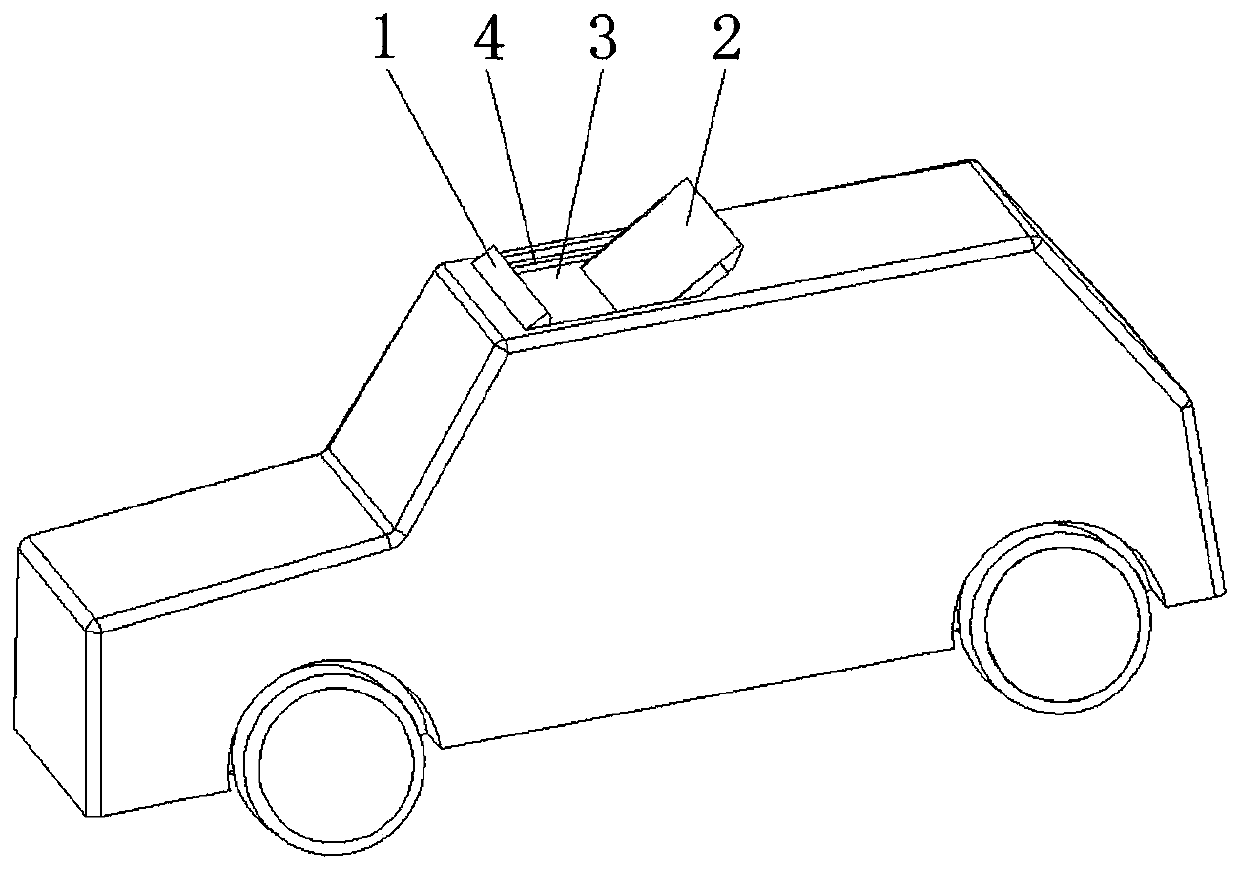

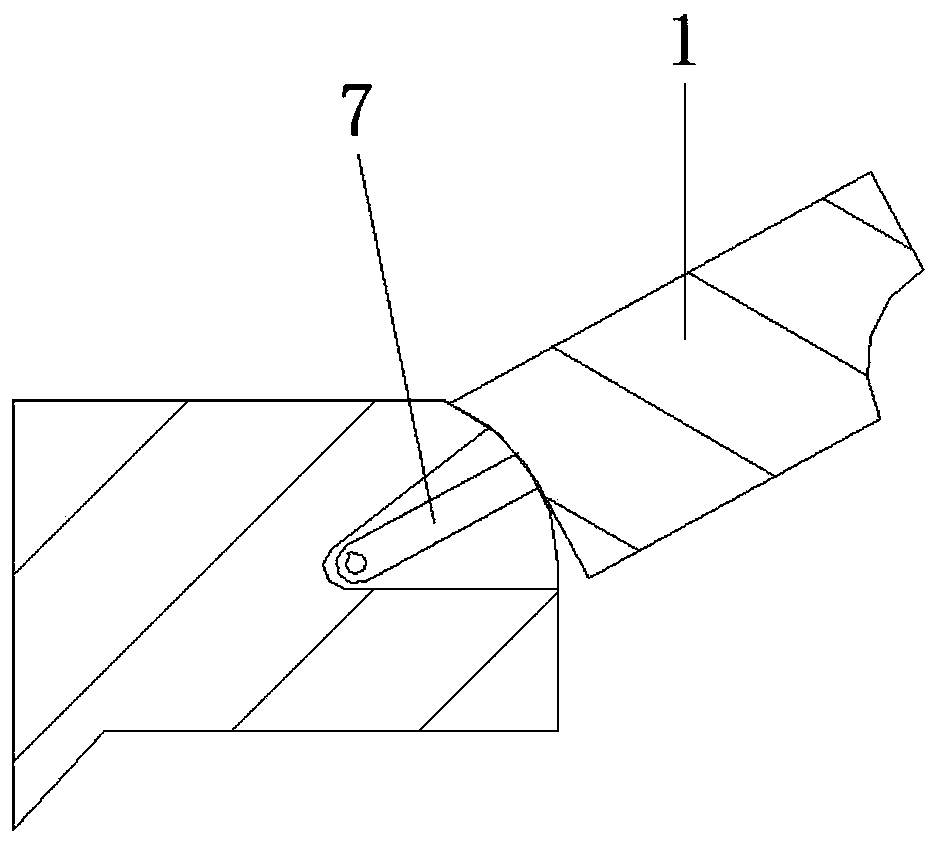

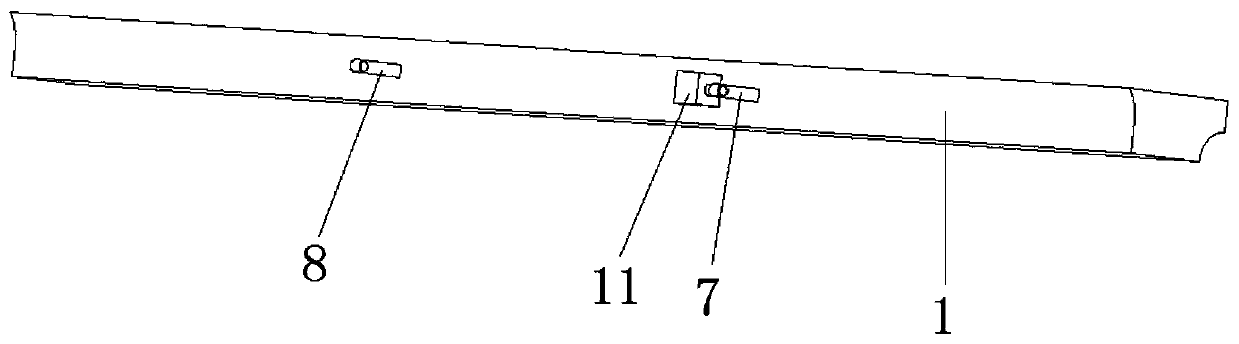

[0041] Such as figure 1 The noise reduction assembly of a sunroof shown includes a front assembly, a rear assembly and a control unit. The front assembly includes a front panel 1 and a front driving mechanism 11, and the rear assembly includes a rear panel 2 and a rear driving mechanism. , The front driving mechanism 11 and the rear driving mechanism are respectively connected to the control unit; the front end of the front panel 1 is connected to the front driving mechanism 11 provided at the front end of the inner edge of the sunroof 3, and the rear end of the front panel 1 It can be turned up and down under the action of the front drive mechanism 11; the rear end of the front panel 2 can be close to the front end surface of the rear panel 2, and the rear end surface of the rear panel 2 can be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com