Pneumatic punching-in tool

A technology of driving into tools and air type, applied in the direction of nailing tools, manufacturing tools, etc., can solve problems such as difficulty in suppressing wind noise, achieve the effect of ensuring stability and improving the assembly state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of an air driving tool for carrying out the present invention will be described with reference to the drawings.

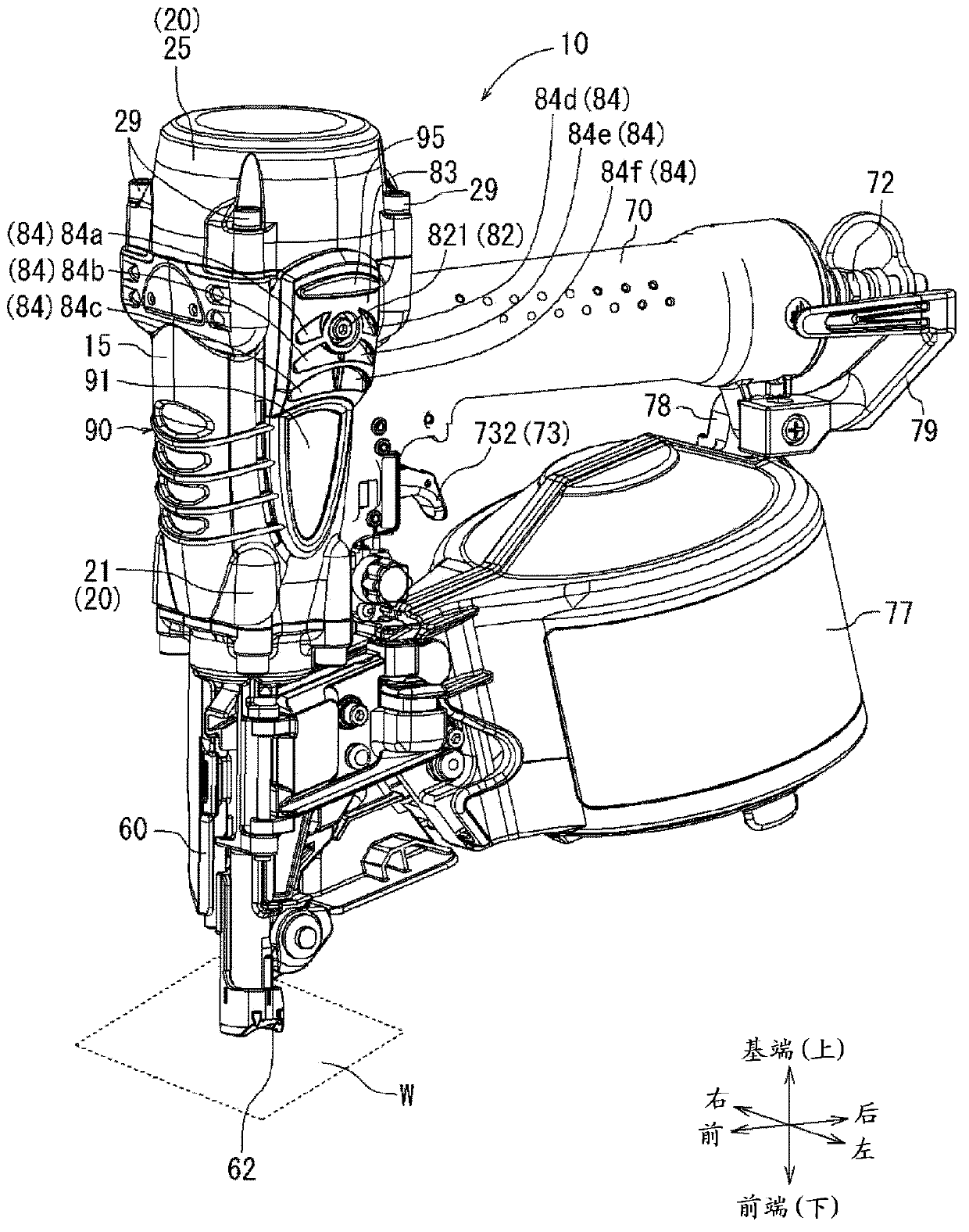

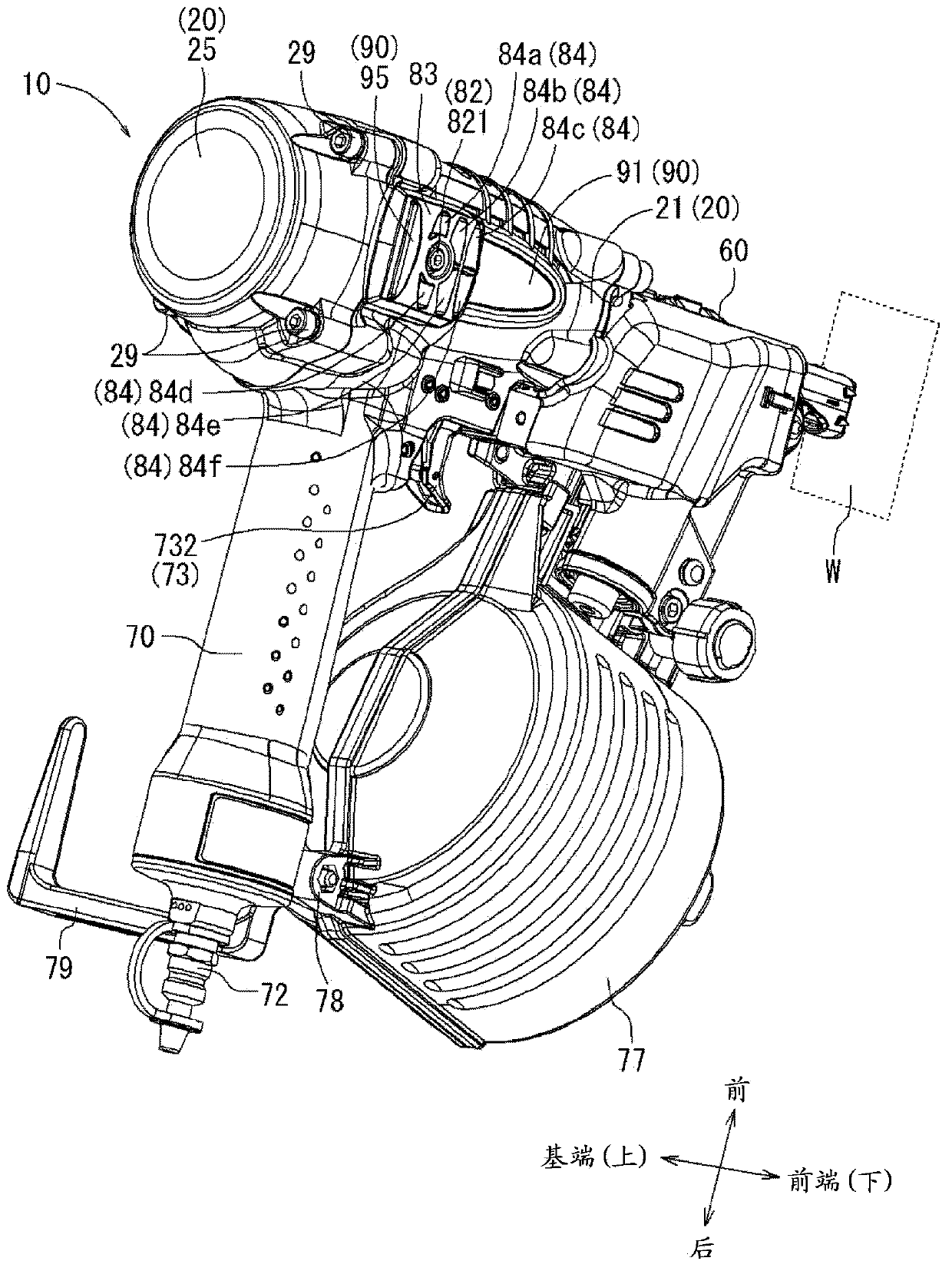

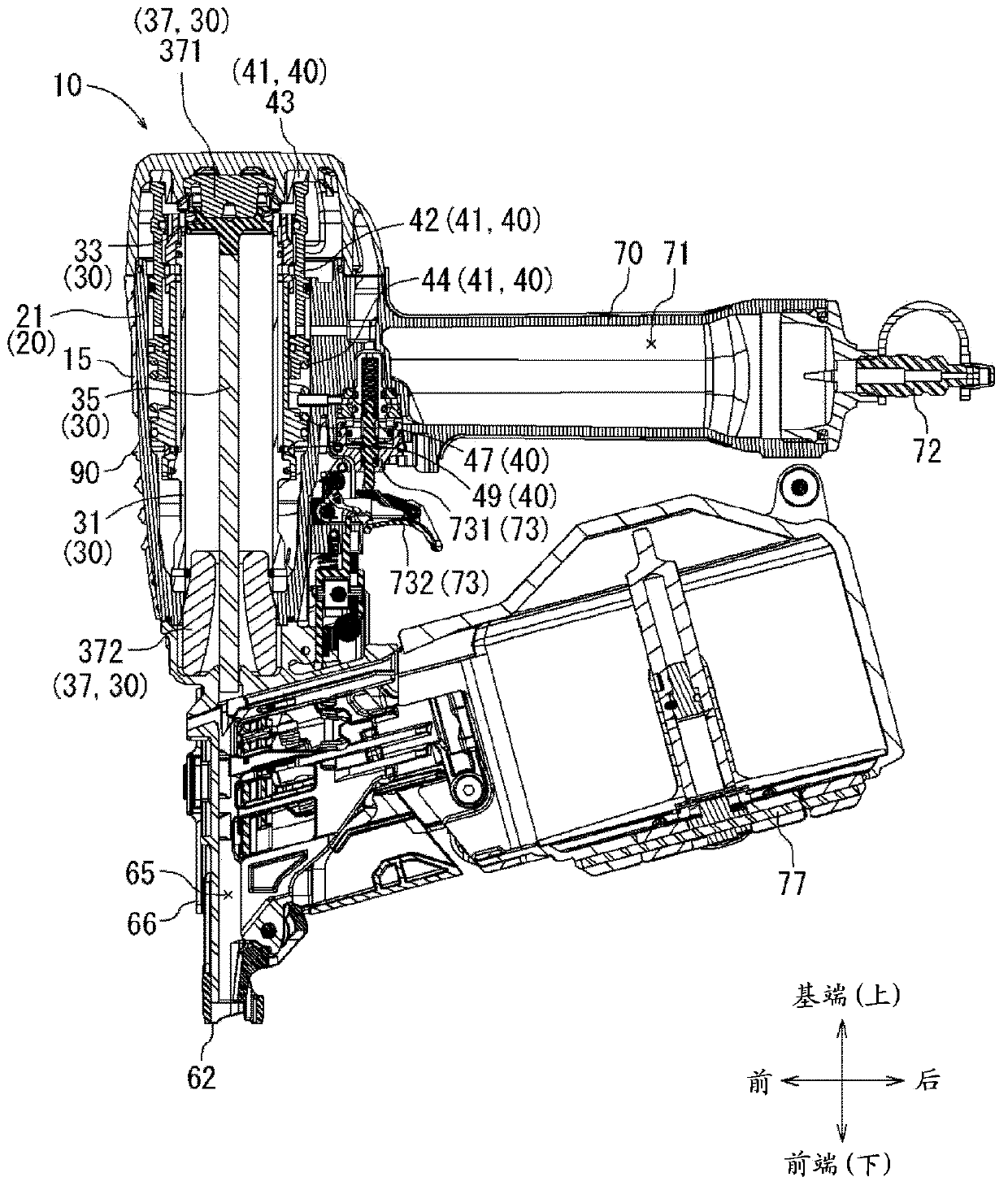

[0036] figure 1 as well as figure 2 In , an air driving tool 10 using compressed air as a driving source is shown. The air driving tool 10 is a driving tool configured as an air nail driving machine that drives a nail (not shown) as a driver. also, figure 1 This is an overall appearance view of the tool showing the overall appearance of the air driving tool 10 at an oblique angle. figure 2 so with figure 1 The overall appearance of the air driving tool 10 is shown at different oblique angles. image 3 This is an overall sectional view of the tool showing the internal structure of the air driving tool 10 in half section. in addition, Figure 4~Figure 7 It is a cross-sectional view showing the internal structure of the tool body 15 in the driving operation state of the air driving tool 10 . which is, Figure 4 is a cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com