a packaging machine

A packaging machine and packaging bag technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of low packaging efficiency, waste of manpower and time, and achieve the effect of efficient automatic packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

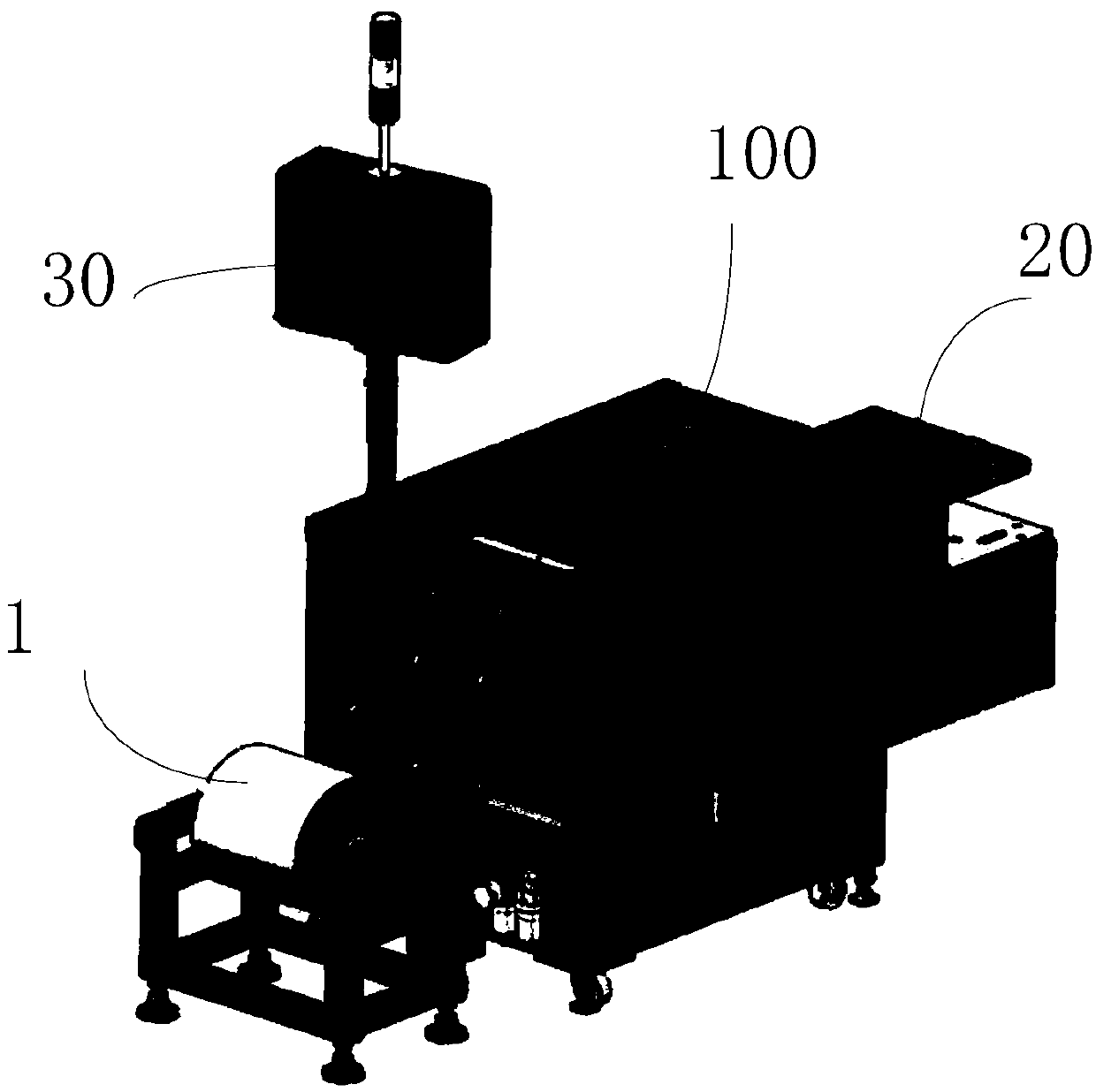

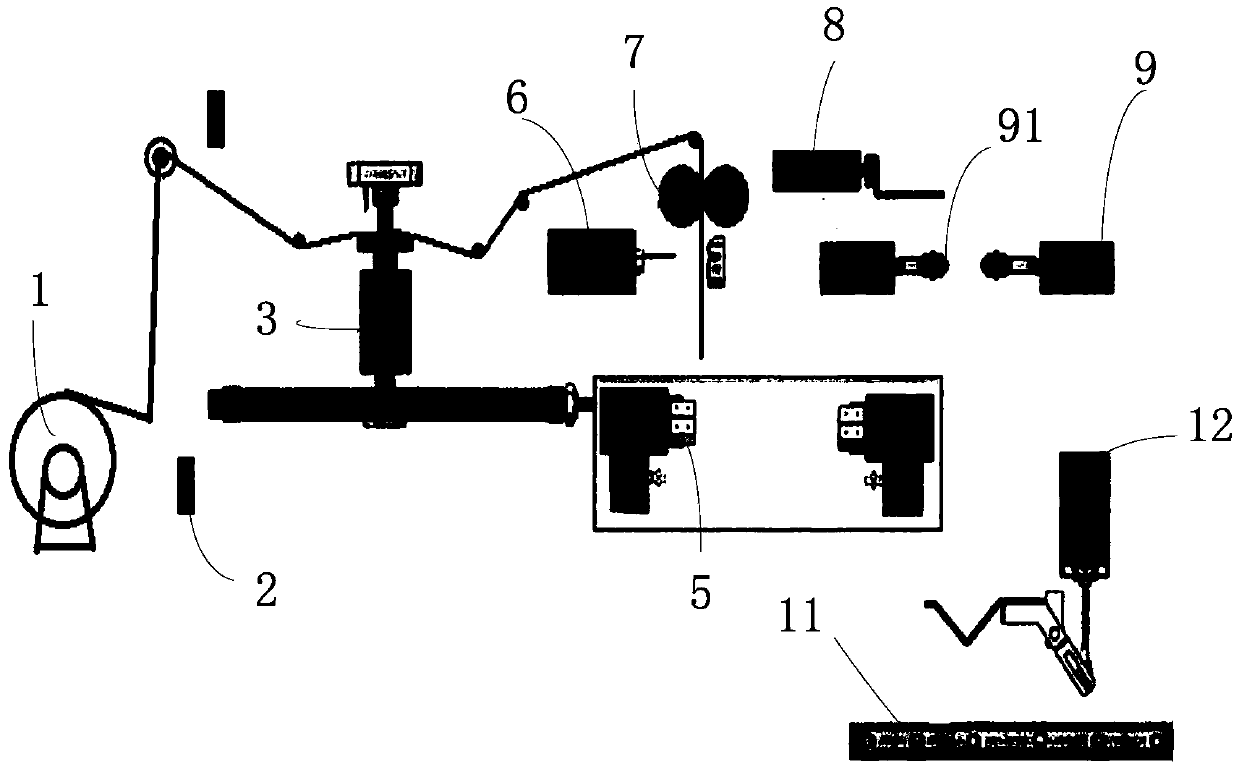

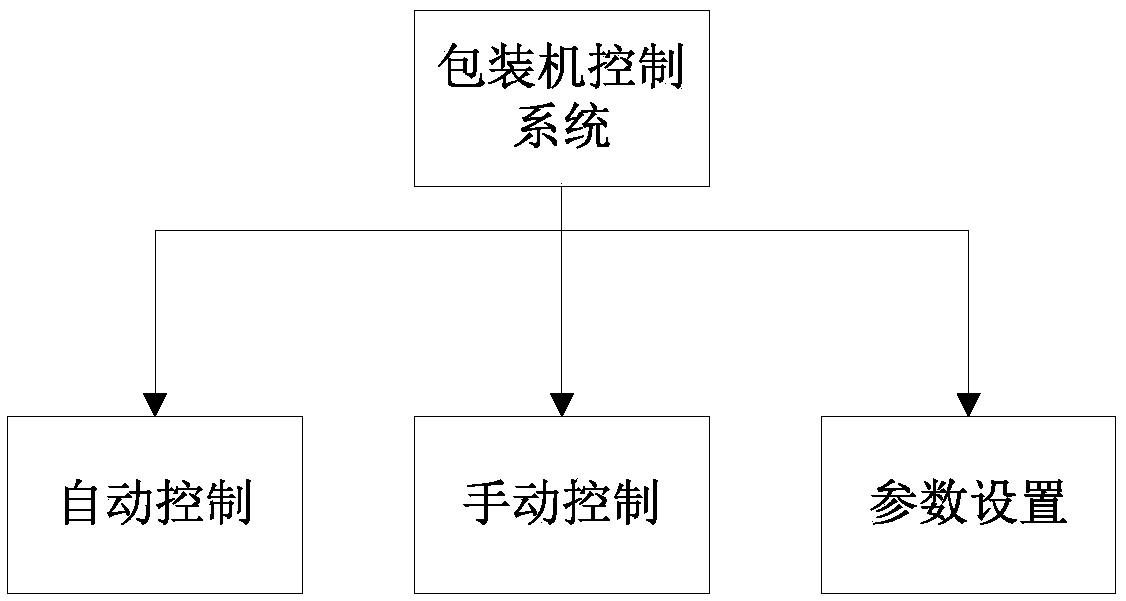

[0022] refer to Figure 1-4 As shown, a packaging machine, such as figure 1 , figure 2 As shown, the complete machine 100 is included, and the complete machine 100 includes a packaging bag reel 1, a sealing device 3, a driving device 7, a cutting device 6, a clamping device 5, a suction device 9, a supporting device 12, a conveyor belt 11. Discharge tray 20, control system 30; the packaging bag is wound on the packaging bag reel 1; the sealing device 3 is used to load the workpiece with packaging and seal the packaging bag; the driving device 7. Conveying the packaging bag; the cutting device 6 is used to cut and separate the sealed packaging bag; the clamping device 5 is used to clamp the packaging bag that has been cut and separated; the suction device 9 is used to It is used to pick up the packaging bag clamped by the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com