Grouting shrinkage compensation method

A compensation method and grouting port technology, applied to structural elements, building components, building reinforcements, etc., can solve problems such as grouting difficulties, and achieve the effects of simple grouting process control, reduced process requirements, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

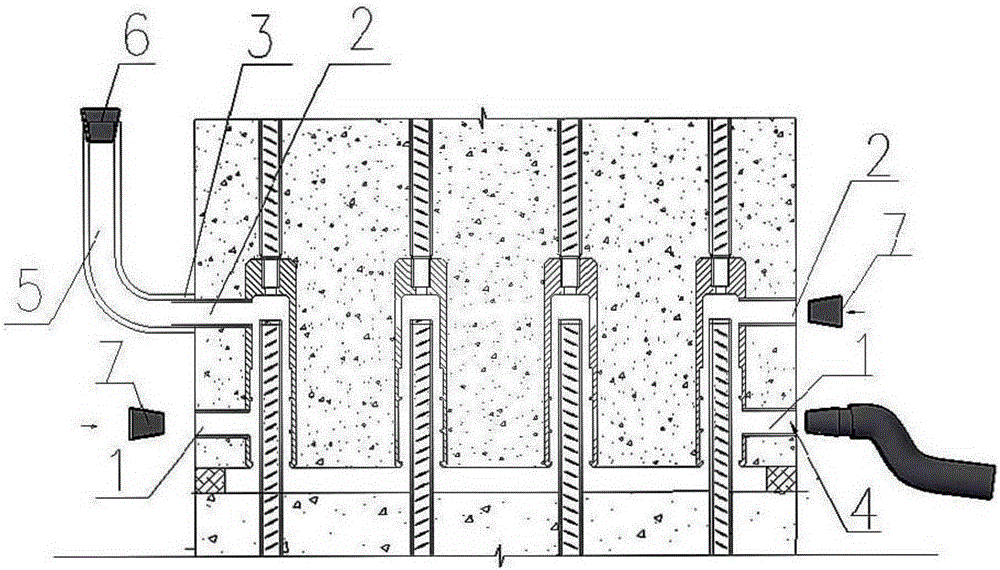

[0033] Such as Figure 1-2 As shown, the grouting shrinkage compensation method of this embodiment is used to compensate for the shrinkage of the grout volume caused by exhaust and water absorption when the vertical connection of the prefabricated concrete structure is grouted by the Unicom cavity, and mainly includes the following steps:

[0034] (1) When preparing for grouting, choose to determine a grouting port 1 as the grouting port 4, and one or more grouting ports 2 to install feeding risers 5. When the size of the Unicom cavity is small, only one riser can be used , it is preferentially installed on the slurry discharge port farthest from the filling port; when the size of the communication cavity is large, two or more risers can be installed and evenly distributed in each position of the communication cavity. Install the riser installation joint 3 on the discharge port where the feeding riser is installed. The slurry discharge pipe reserved outside the wall can be us...

Embodiment 2

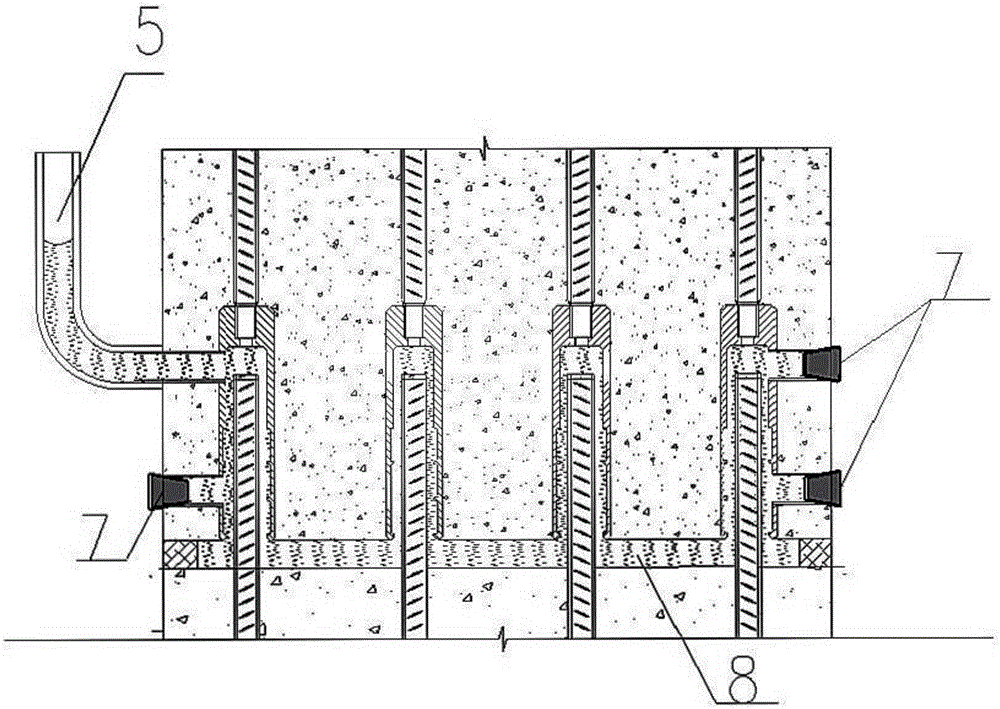

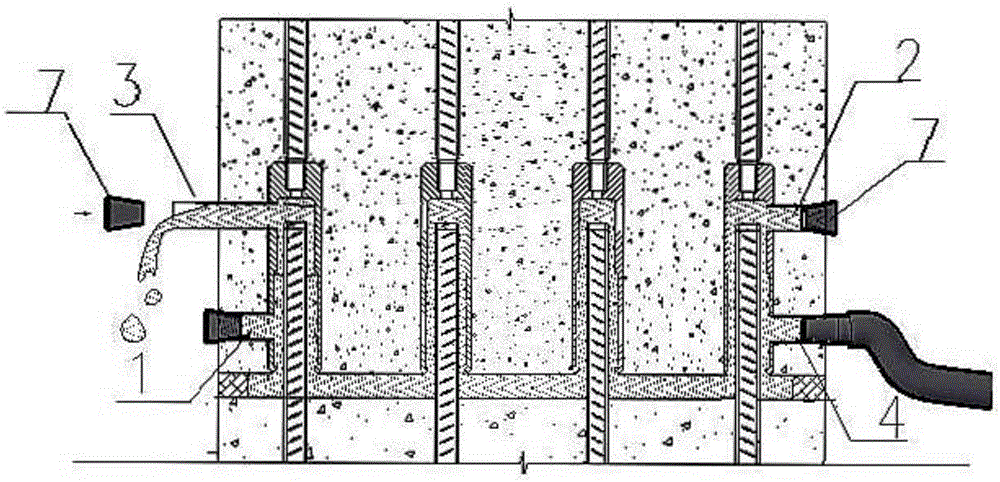

[0039] Such as Figure 3-Figure 5 As shown, the grouting shrinkage compensation method of this embodiment is used to compensate for the shrinkage of the grout volume caused by exhaust and water absorption when the vertical connection of the prefabricated concrete structure is grouted by the Unicom cavity, and mainly includes the following steps:

[0040] (1) Same as embodiment one step (1).

[0041] (2) Use the pressure grouting method to inject the grouting material from the filling port 4. During the grouting process, when the grout flows out from the grouting port 1 or the grouting port 2, immediately block it with the grouting port and the grouting port plug 7 until all grouting After the grout is discharged from the port (except the pouring port) and the grouting port, the grouting is suspended.

[0042](3) Remove the plug 7 on the riser installation joint 3, install the feeding riser 5 on the installation joint 3, and continue grouting until the slurry in the riser 5 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com