Edge sealing method for injected compound pavement grouting construction

A compound pavement and pouring technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems that adjacent roads are easily polluted, the foaming agent is not sprayed evenly, and is not beautiful, so as to improve the appearance and construction quality of the pavement , Reduce construction cost, good grout sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

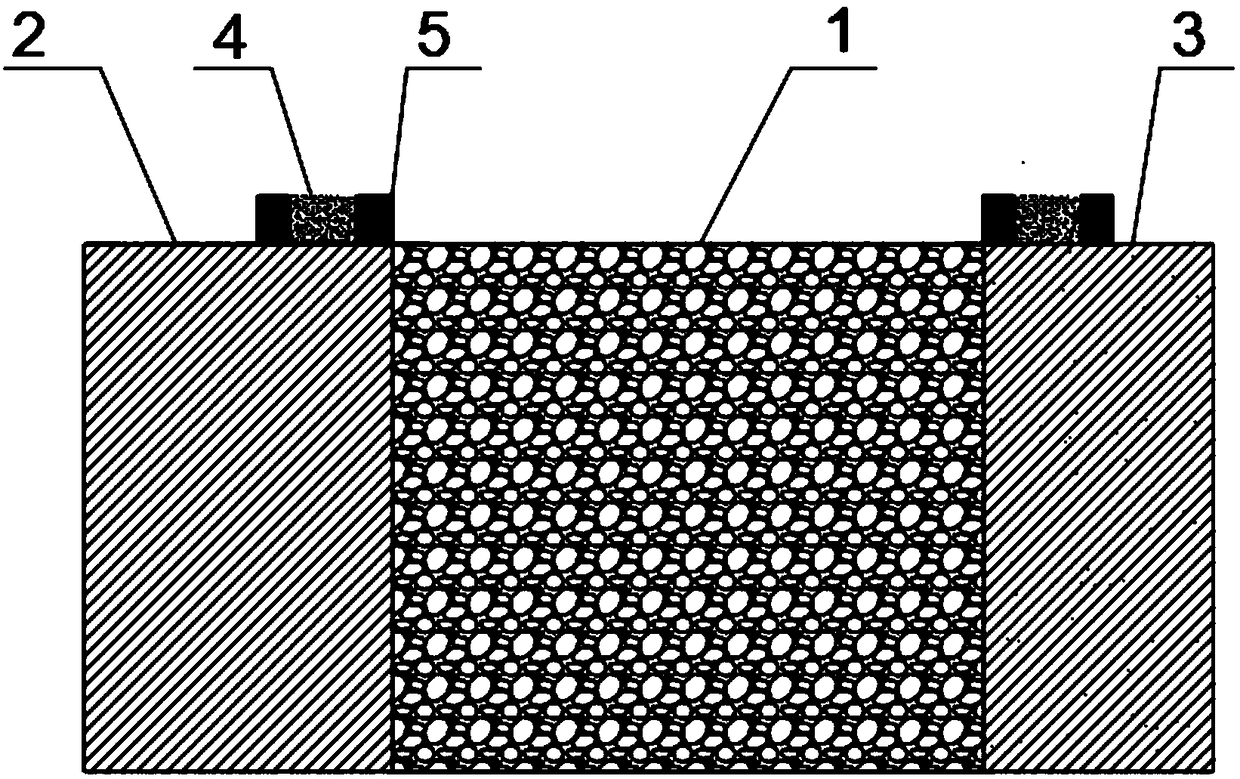

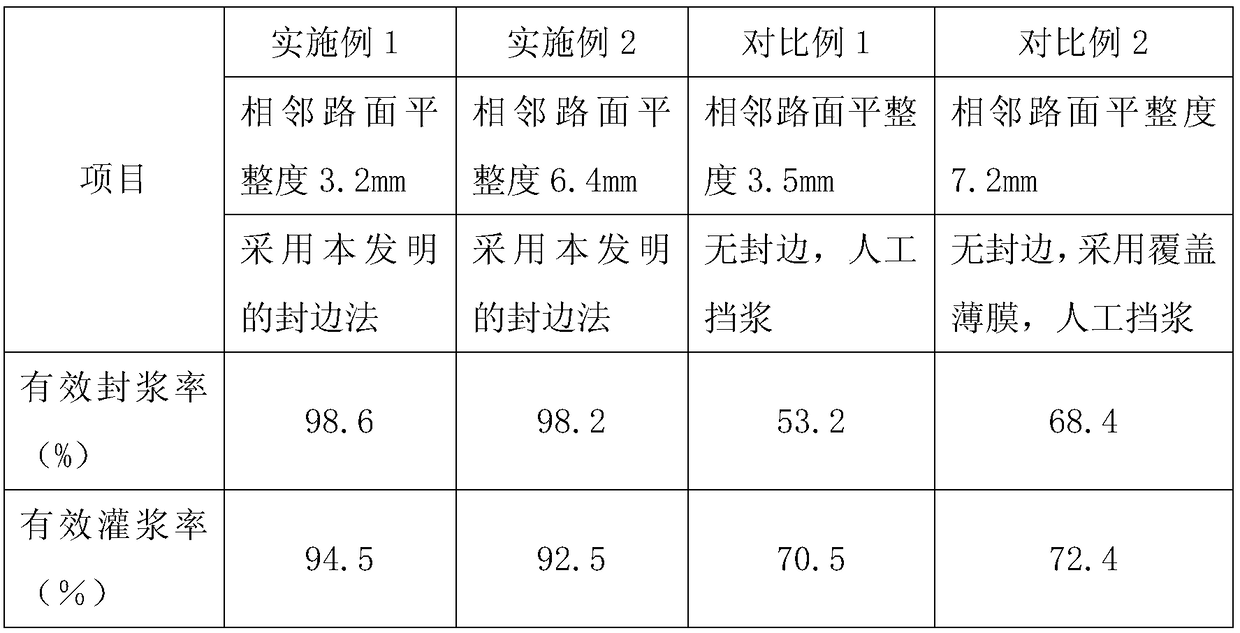

[0023] The average flatness of the adjacent asphalt pavement 3 is 3.2mm before construction of the poured composite pavement, and the flatness of the pavement is relatively good. During the cooling process after the asphalt mixture with large pores is paved, before the grouting construction, use a forest fire blower and a broom to clean up the asphalt pavement 3 or curbstone 2 adjacent to the grouting area 1, and then in the grouting area 1 Two rows of edge banding strips with a certain height and weight are placed in parallel on both sides along the length direction of the grouting area. The width of a single edge banding strip 5 is 5cm, the height is 5cm, and the length is 400cm. The material is rubber. Construction conditions Tightly splice the edge banding strips 5 section by section along the length direction of the grouting area. The gaps between the strips 5 are filled, and the edge strips 5 are removed after the mortar is formed. The filling material 4 is early-streng...

Embodiment 2

[0025] The average flatness of the adjacent asphalt pavement 3 is 6.4mm before the construction of the poured composite pavement, and the flatness of the road surface is poor. During the cooling process after the asphalt mixture with large pores is paved, before the grouting construction, use a forest fire blower and a broom to clean up the asphalt pavement 3 or curbstone 2 adjacent to the grouting area 1, and then in the grouting area 1. Two rows of edge banding strips 5 with a certain height and weight are placed in parallel on both sides along the length direction of the grouting area. The width of a single edge banding strip 5 is 5 cm, the height is 8 cm, and the length is 600 cm. The material is rubber. The specific construction conditions are to closely splice the edge strips 5 one by one along the length direction of the grouting area. The gap between the two rows of edge strips 5 is controlled between 1cm and 3cm. The gap between the edge strips 5 is filled, and the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com