Edge sealing method for grouting construction of grouting-type composite pavement

A composite pavement, pouring technology, applied in roads, roads, road repair and other directions, can solve problems such as unsatisfactory enclosure effect, insufficient slurry filling, and inability to form, to improve the appearance and construction quality of the pavement, reduce Construction cost and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

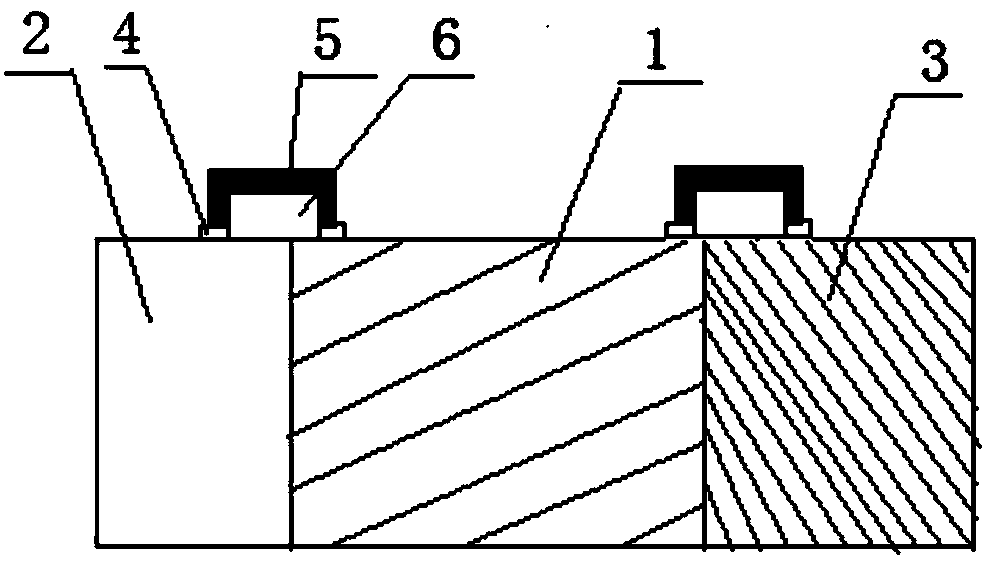

[0020] figure 1 It is a cross-sectional view of the pavement structure during the edge sealing of the pouring composite pavement grouting construction of the present invention.

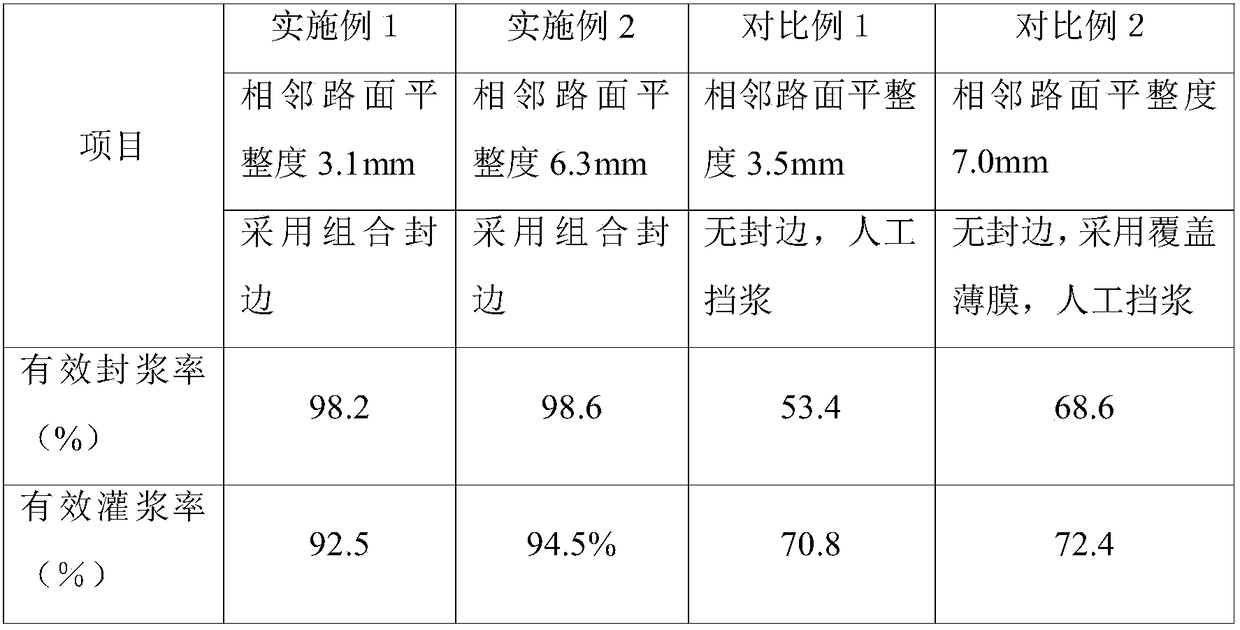

[0021] The average flatness of the adjacent asphalt pavement before construction of the poured composite pavement is 3.1mm, which is good. During the cooling process after the large-pore asphalt mixture is paved, before the grouting construction, use a forest fire blower and a broom to clean up the asphalt pavement 3 and curb 2 adjacent to the grouting area 1, and then clean the grouting area 1 Adjacent all around put foam spacer strip 6 (material is polyurethane sponge, the single size that adopts is: wide 10cm, height 5cm, length 400cm), press channel steel bar 5 on foam spacer strip 6 again (single size is: Width 12cm, height 5cm, length 400cm), at last the gap between the road surface and the foam isolation strip 6 is filled up with leak-stopping agent 4 (water-based silica gel).

Embodiment 2

[0023] The average flatness of the adjacent asphalt pavement before construction of the poured composite pavement is 6.3 mm, which is poor, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com